Kooperatives Forschungsprojekt mit Alcantara S.p.A.

Team

Prof. Axel Kufus

Dipl. Des. Jörg Höltje

Guest Teachers

Jerszy Seymour

Klaudia Kruse

Fabian Hemmert

Marco Dessi

18 Students

Bettina Bühr

Camilla Richter

Eva Feldkamp

Christ van Leest

Franziska Müller

Fynn Freyschmidt

Malte Licht

Gunnar Sören Petersen

Julinka Ebhardt

Lene Fischer

Magdalena Kovarik

Ulf Brauner

Max Schäth

Milena Kling

Pascal Hein

Stephanie Horing

Theresa Lusser

“supersoft” is softer than soft, “knallhart” is brisker than tough.

Complementary to the luxury which usually forms the backdrop of Alcantara® when used in cars, fashion, yachts and interior design, our project group at Universität der Künste Berlin opted for the radical and experimental, setting out to discover unexpected qualities of surfaces and structures and to explore new combinations of materials and applications. Just as we had agreed upon with Giulio Cappellini, the art director of Alcantara®.

What kind of material is this which can be called neither fabric nor cloth nor substitute leather?

Can we recognize it as skin, fur, peel, membrane, layer, boundary stratum? How does it bristle or nuzzle, when does it tremble or crinkle, vibrate or bleed, tense or wrinkly, face lifted, blown up, irritated, sensitive, strained to the max or completely relaxed. Don’t touch me or touch me.

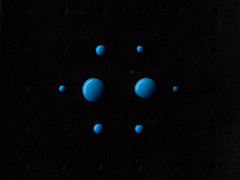

Alcantara® fibers are way too fine to get wet. Instead of getting wet they induce water to contract into drops and roll off. We made use of this hydrophobia and transformed liquid glue into a pearl structure, using specifically perforated materials – an inseparable connection. Alcantara® melts before it burns. Under the brazing flame its edges fuse inseparably with stone, concrete, wood or metal. We used the hot tip of a soldering iron in order to pad a monobloc chair or create flexible hinges with fine “point welding” instead of the usual upholstery nails. Wrinkles are often feared like old age. But how wonderfully can light with all its shadings indulge in the lush lining of an envelope!

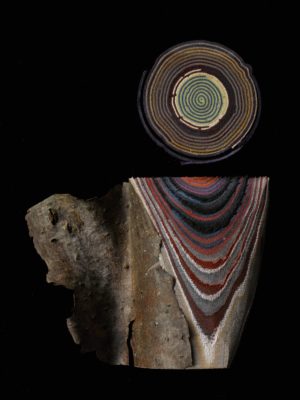

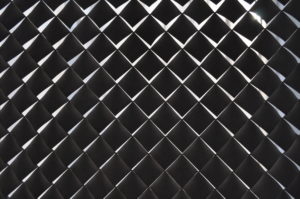

Using various backside coatings we created characteristic wrinkles: latex crumples when tightened, aluminum foil crinkles. Or we used artificial resin to fix the manipulated wrinkles and folds in their desired forms and thus transformed them into stable objects that give a whole new look to Alcantara®. Since its inner structure forms complex interconnections, Alcantara® can hardly be ripped even when split into very thin stripes – it is much more robust than fabric, foils or leather. We used laser to cut intricate geometrical patterns and marveled at the fantastic changes in form that can be induced by tension, pressure, bending or torsion.

Looking at the very different designs developed by the 18 students who participated in the project, these are only some of the issues we wanted to highlight; they are aptly captured and interpreted in the images of photographer Hans Hansen. We were able to unveil the hitherto hidden qualities and potentials of a classic material in very short time – thanks to the experimental courage of our students, the encouragement of the guest teachers we invited and the trustful support of Alcantara Company. In the end it is always the same question design has to face: how to use inventiveness, intelligence and care in order to create artificial objects that can match the unsurpassable examples set by nature.