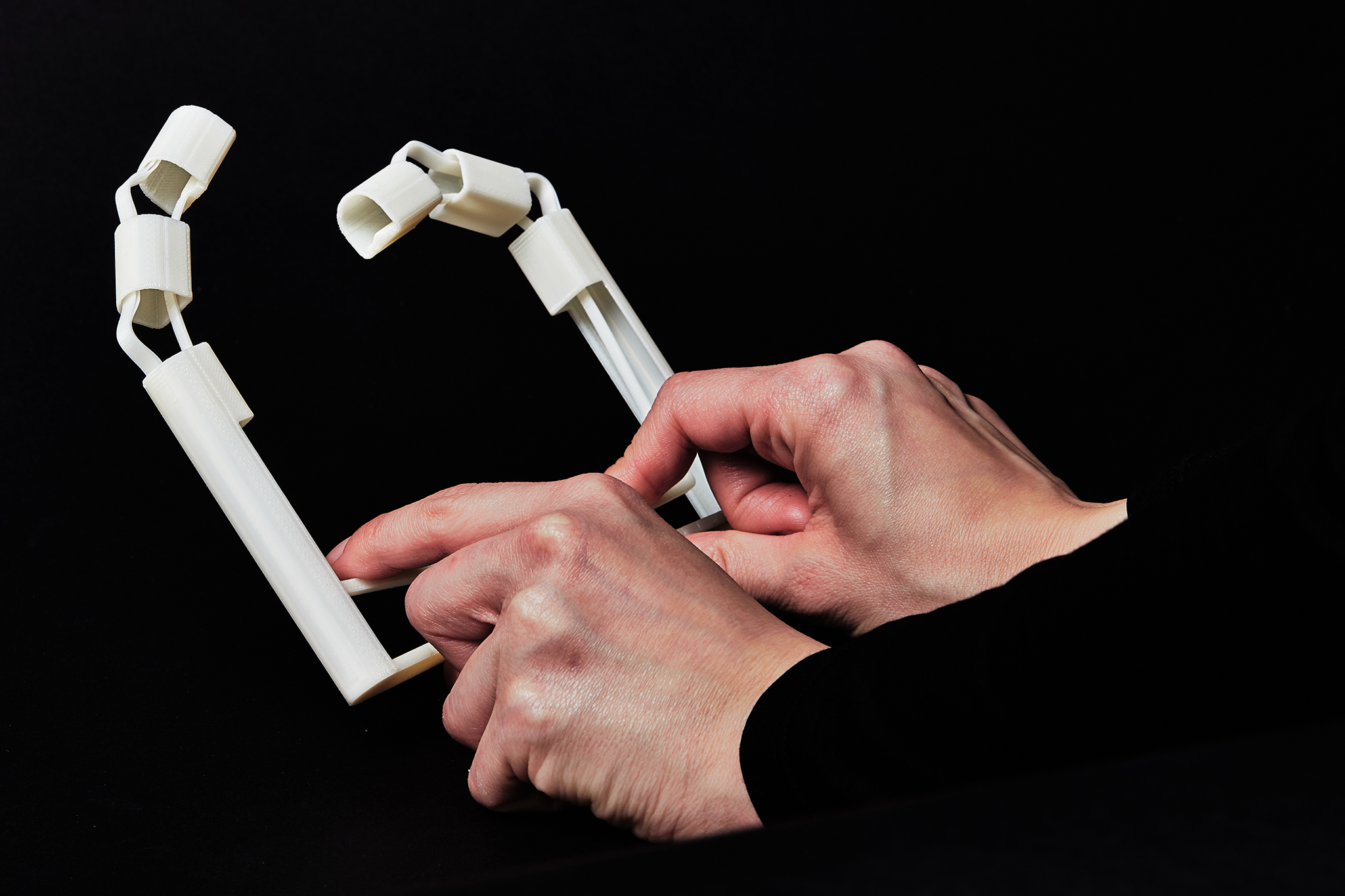

compliance | Bachelorarbeit 2019

Turning off the alarm clock, pulling up the window shades, pushing the button of the coffee machine, opening and locking the door, changing the gears, tapping on the keyboard, unscrewing the wine bottle, switching off the light — all are common daily routines. These routines have one common single success-enabling factor — mechanisms. These products are made possible by their incorporation.

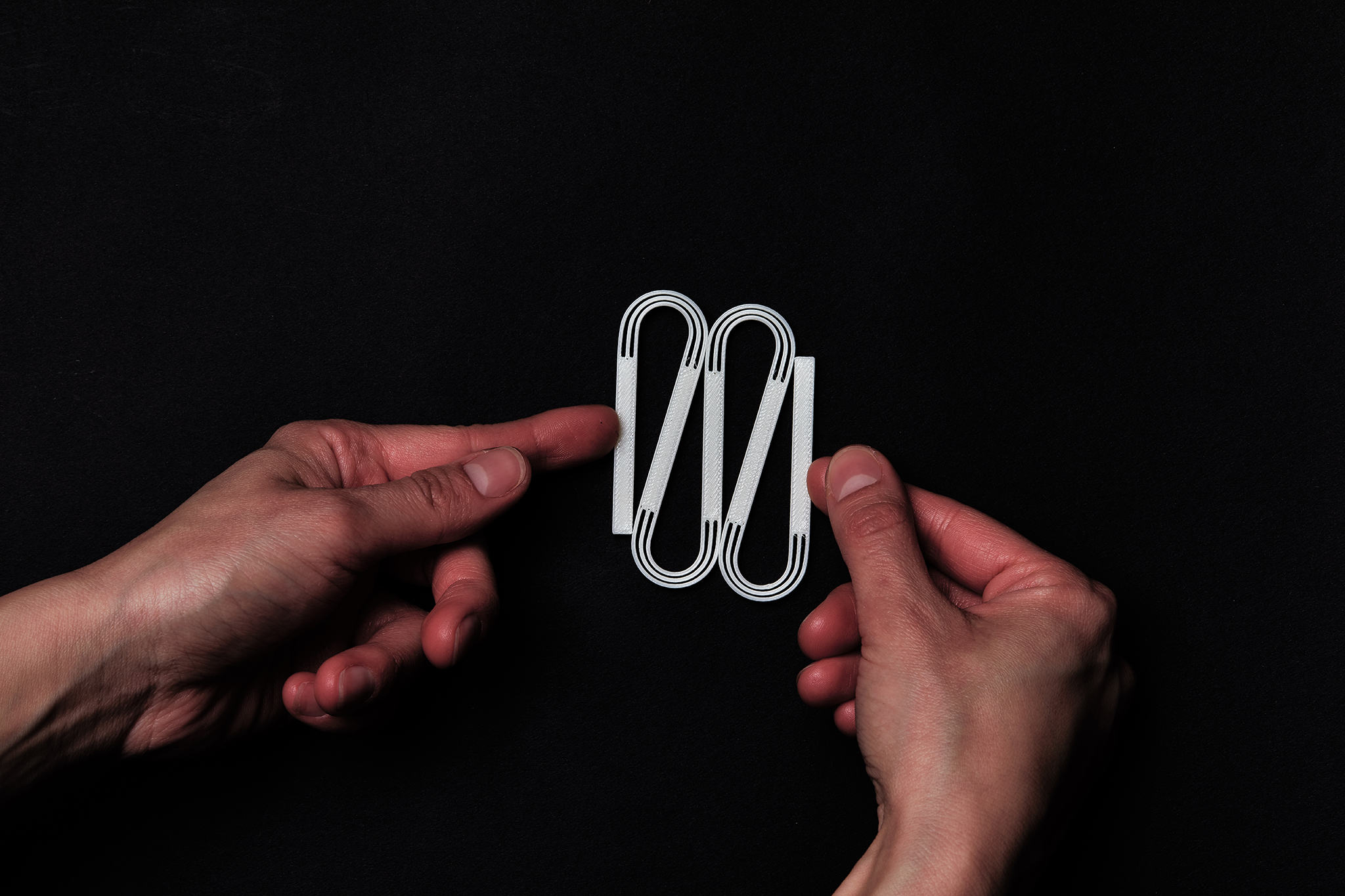

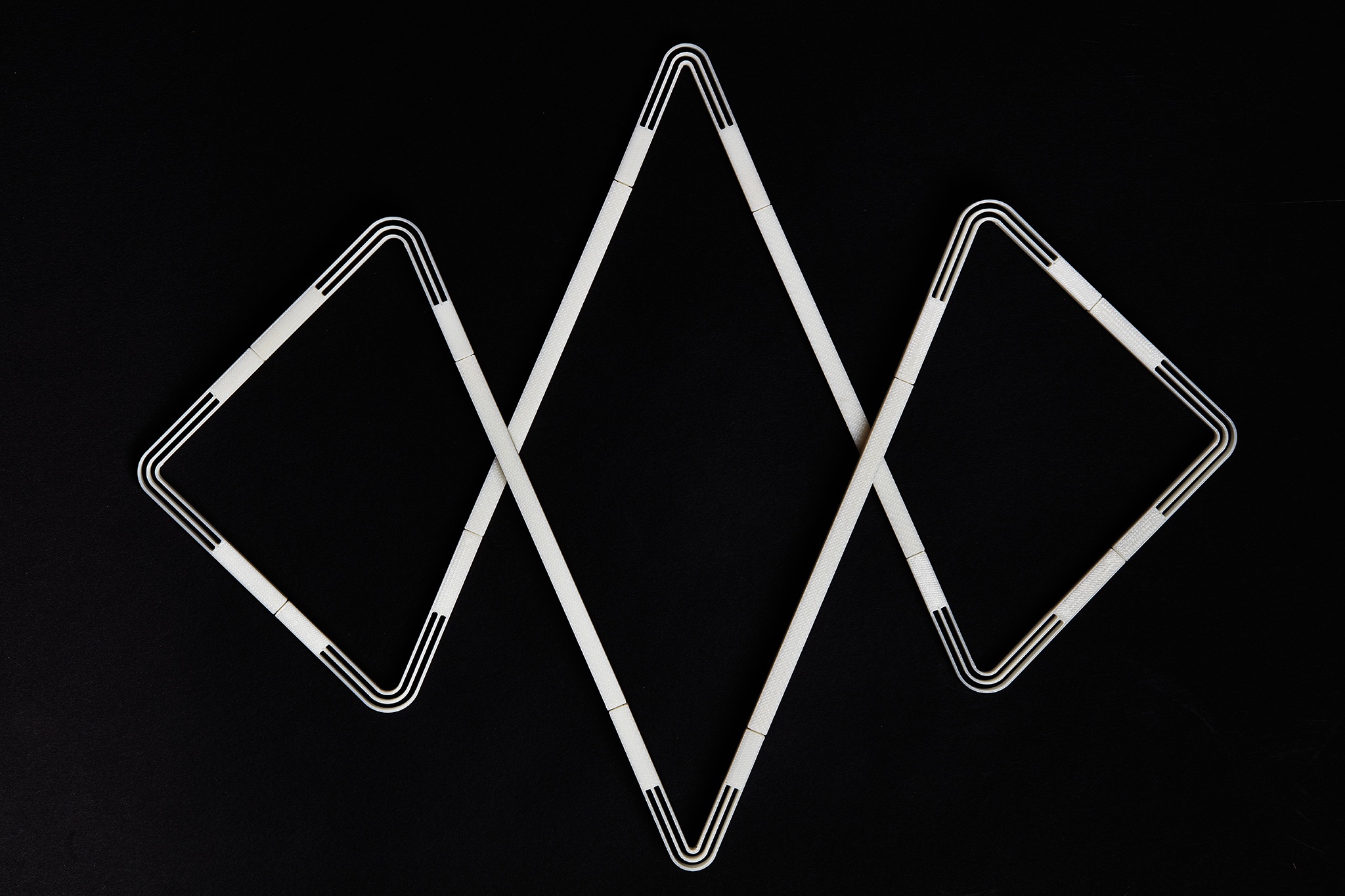

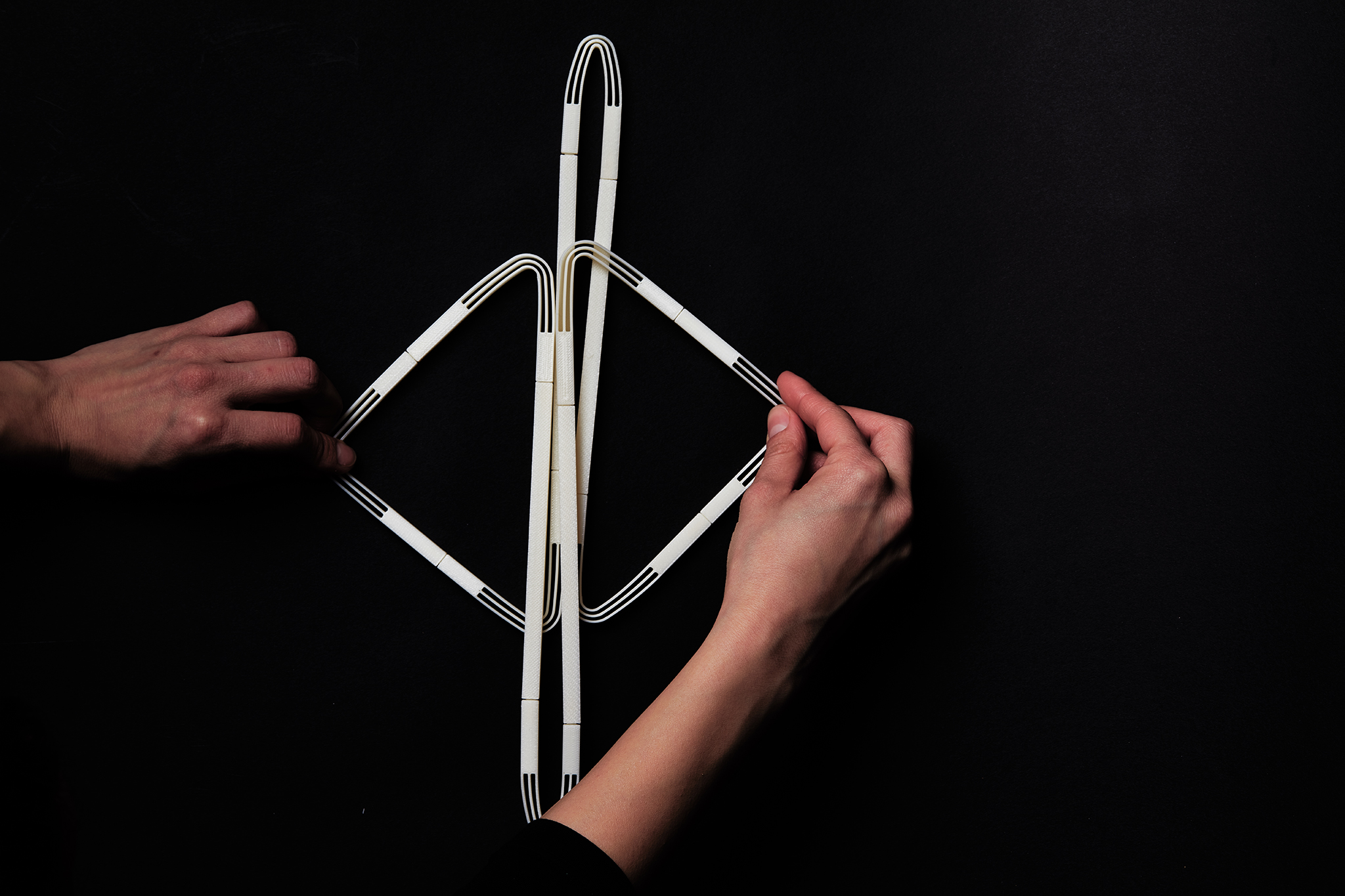

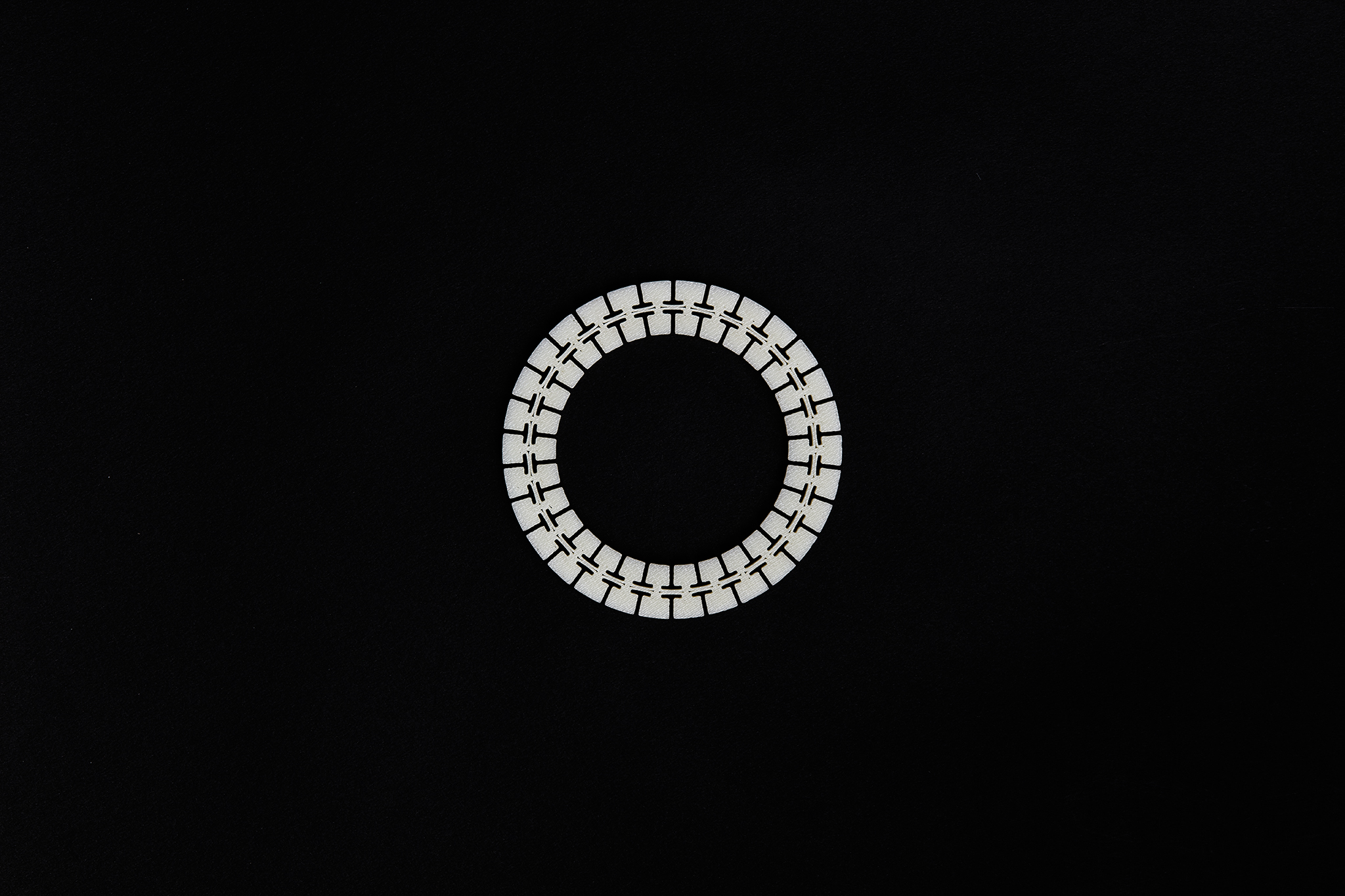

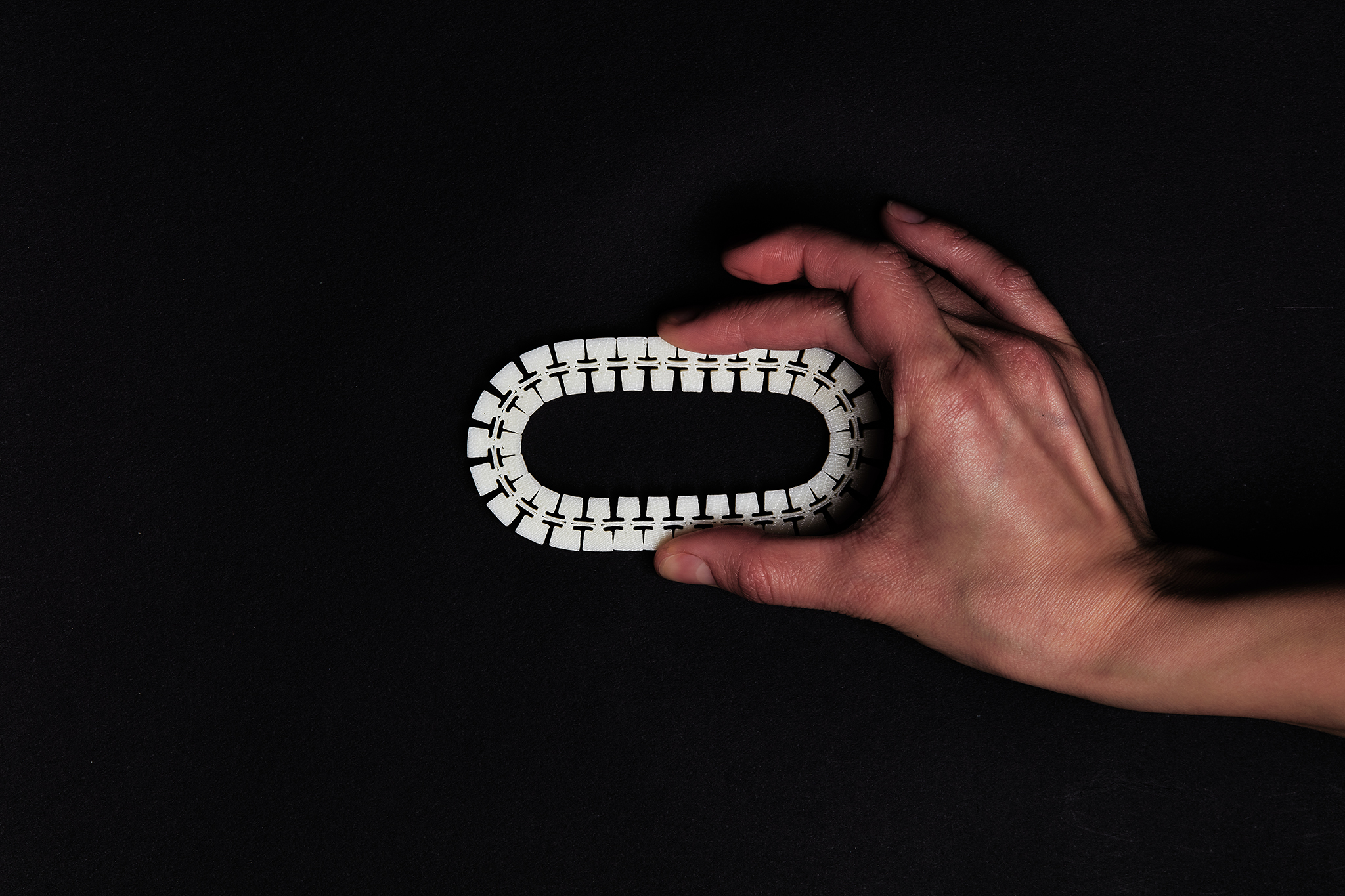

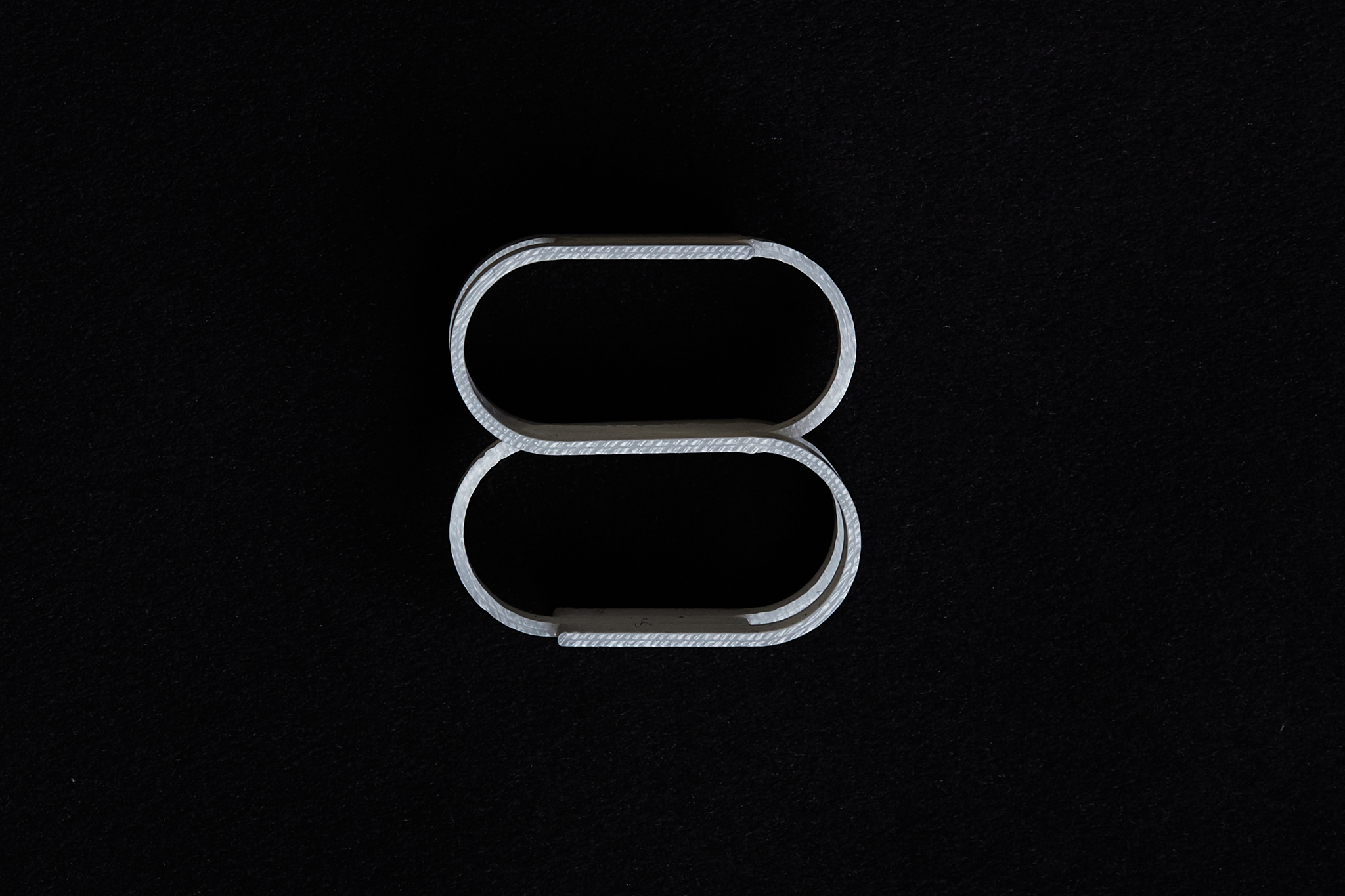

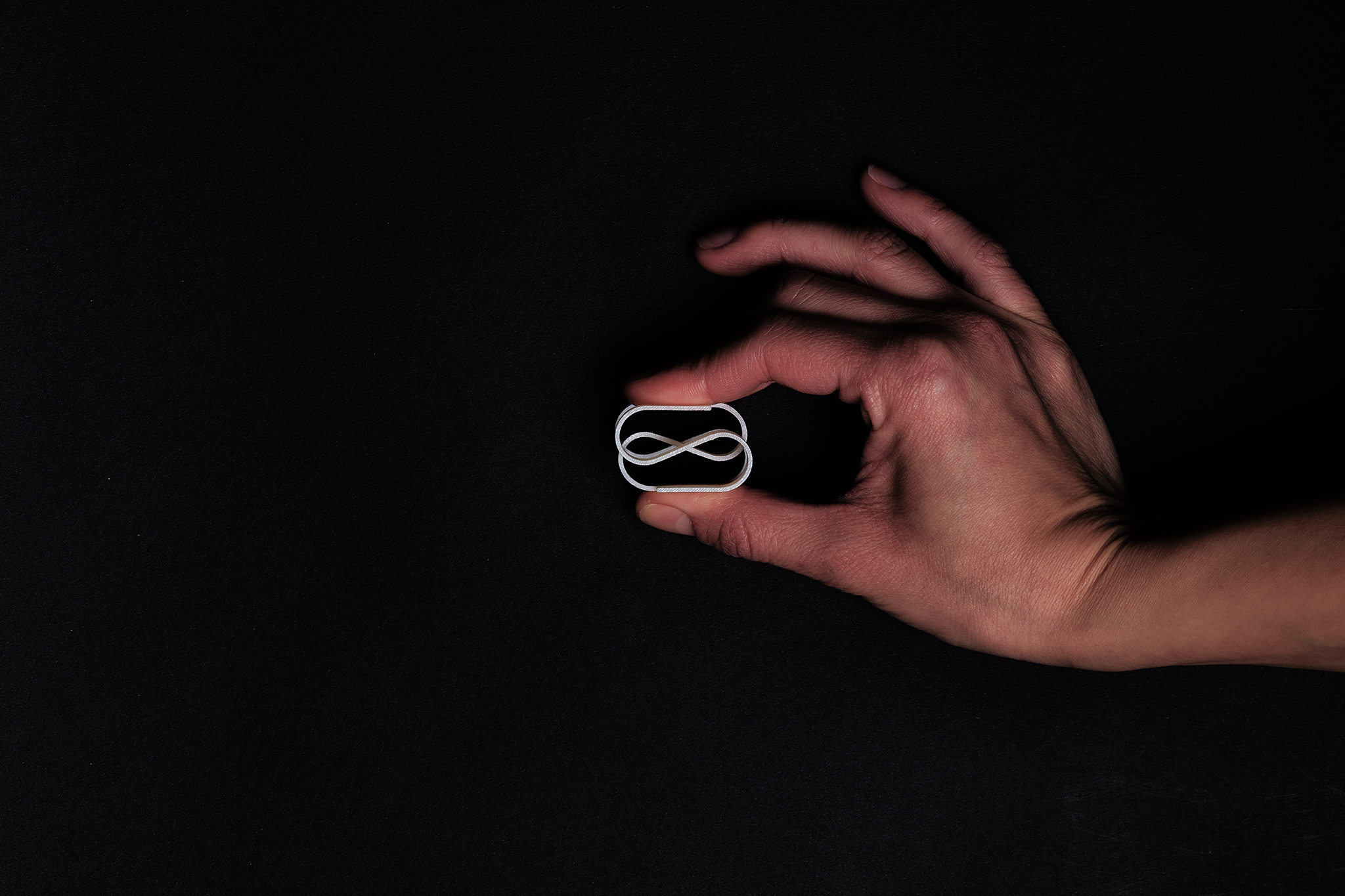

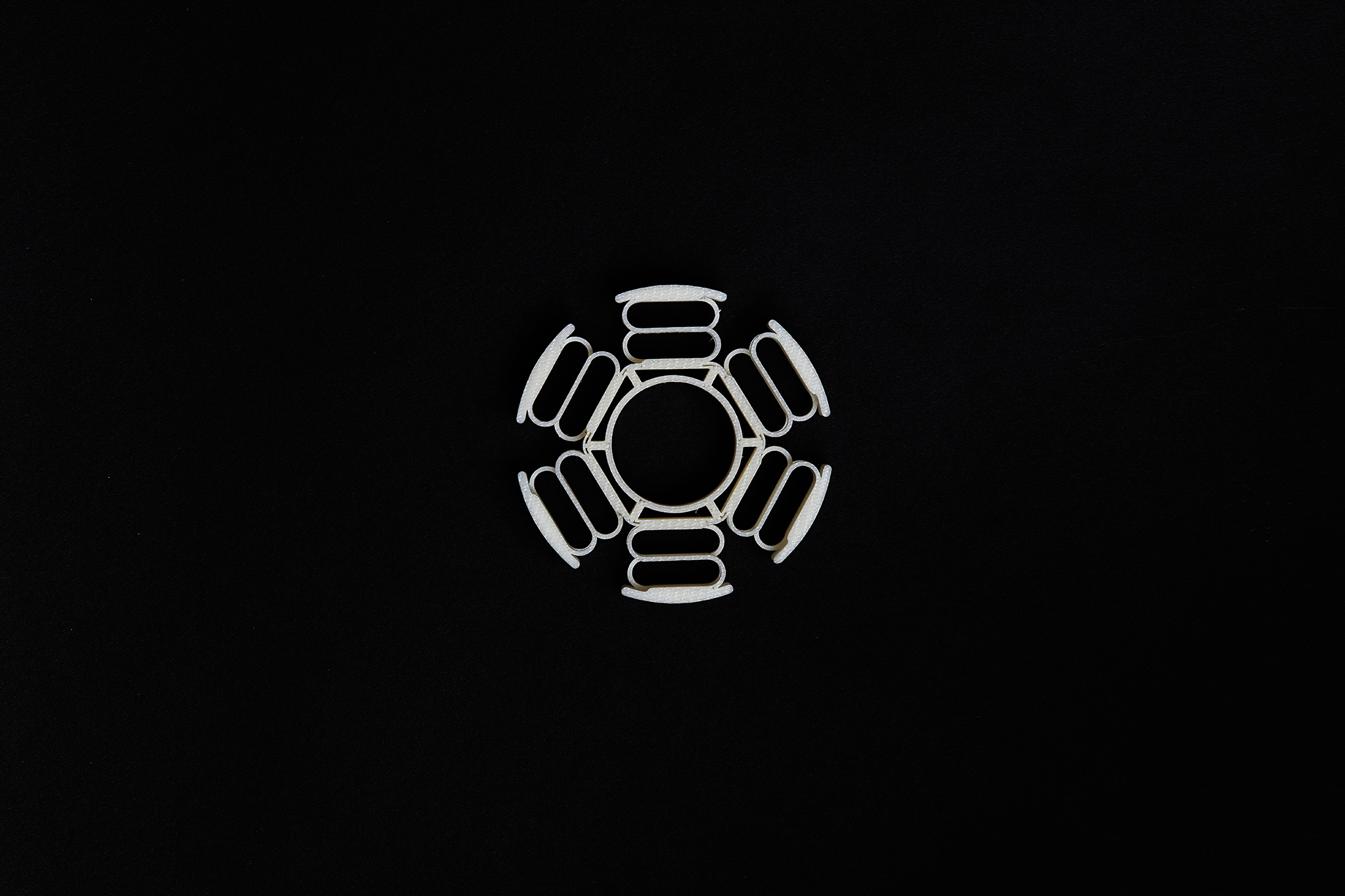

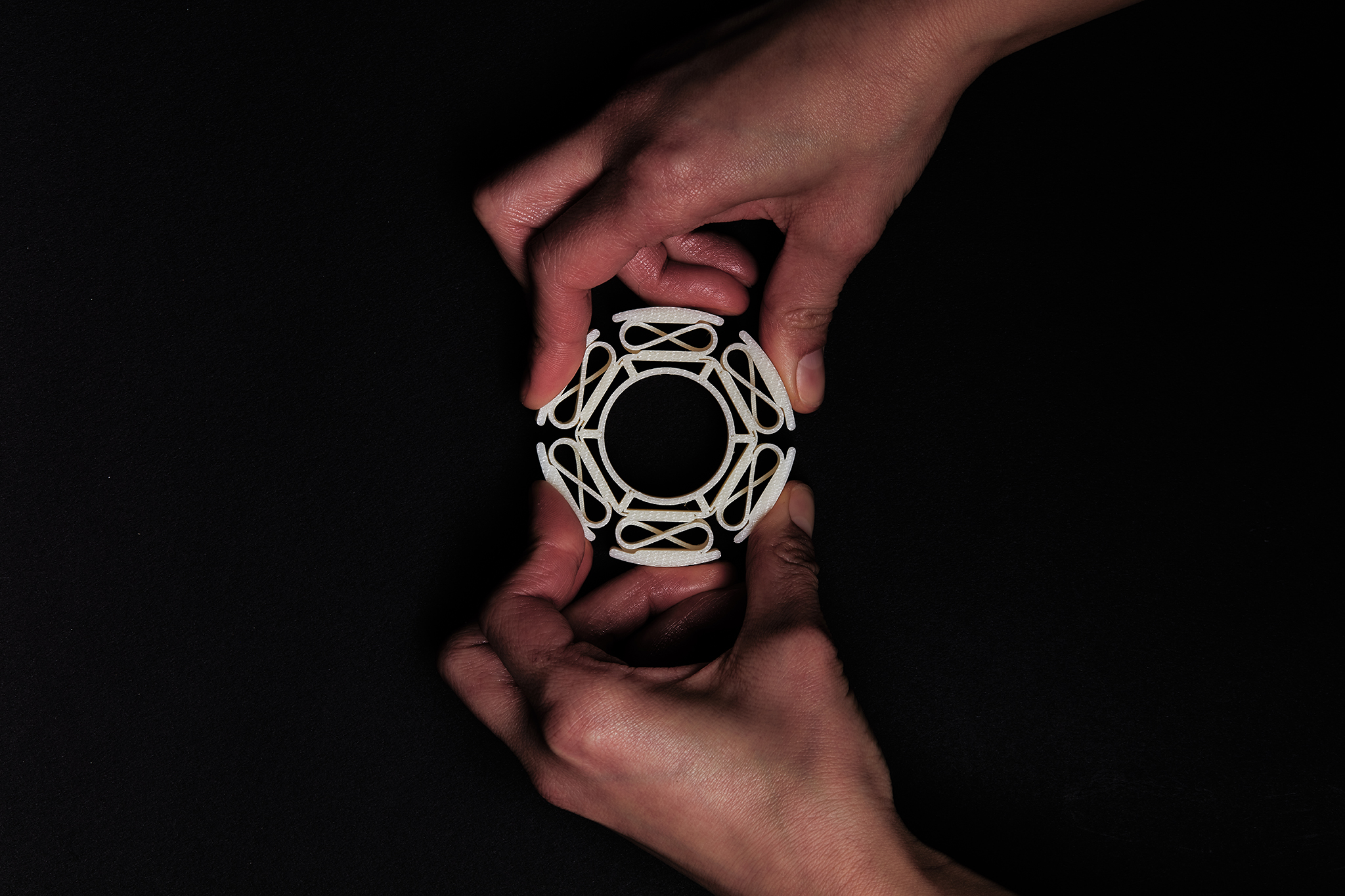

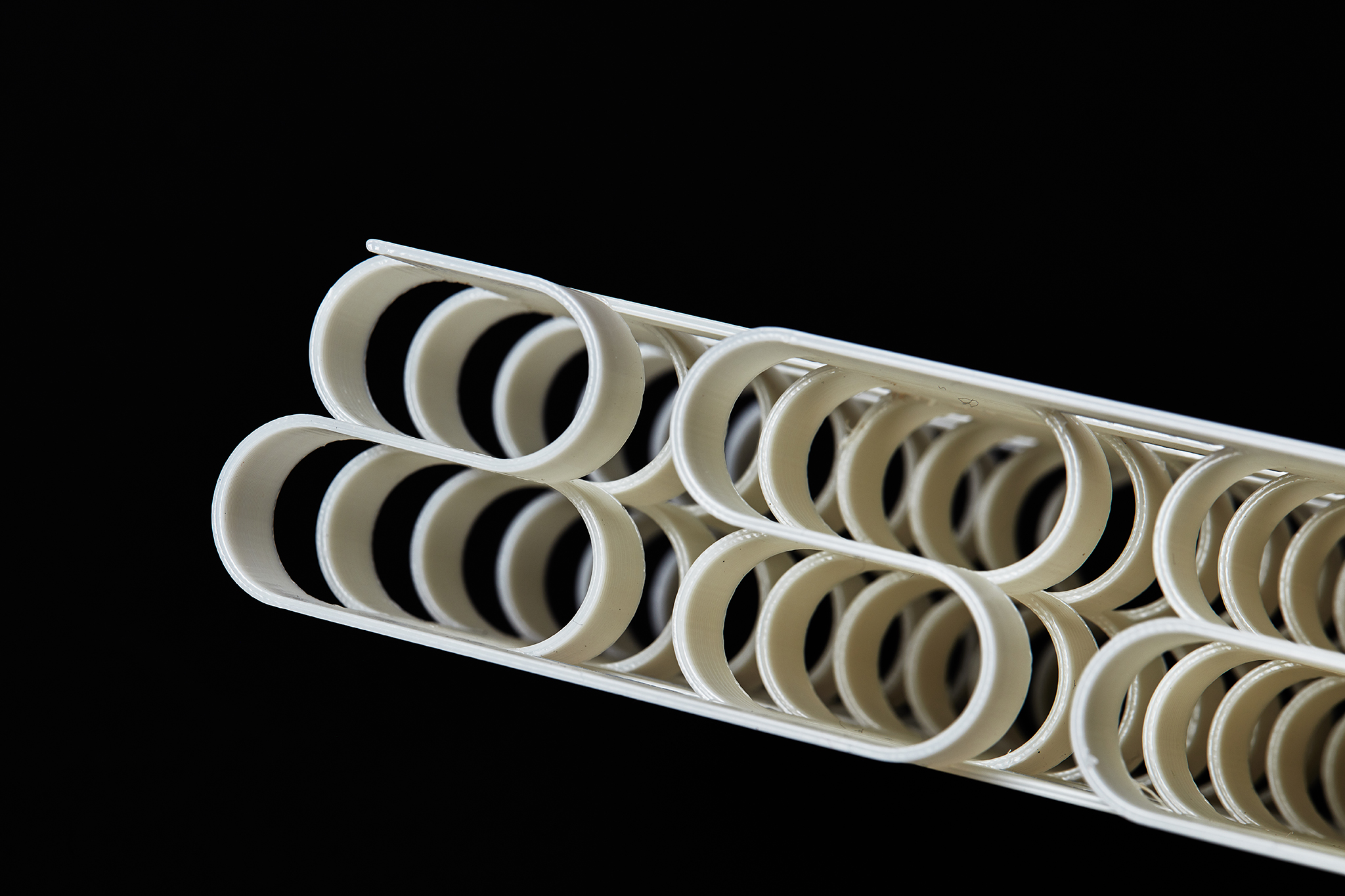

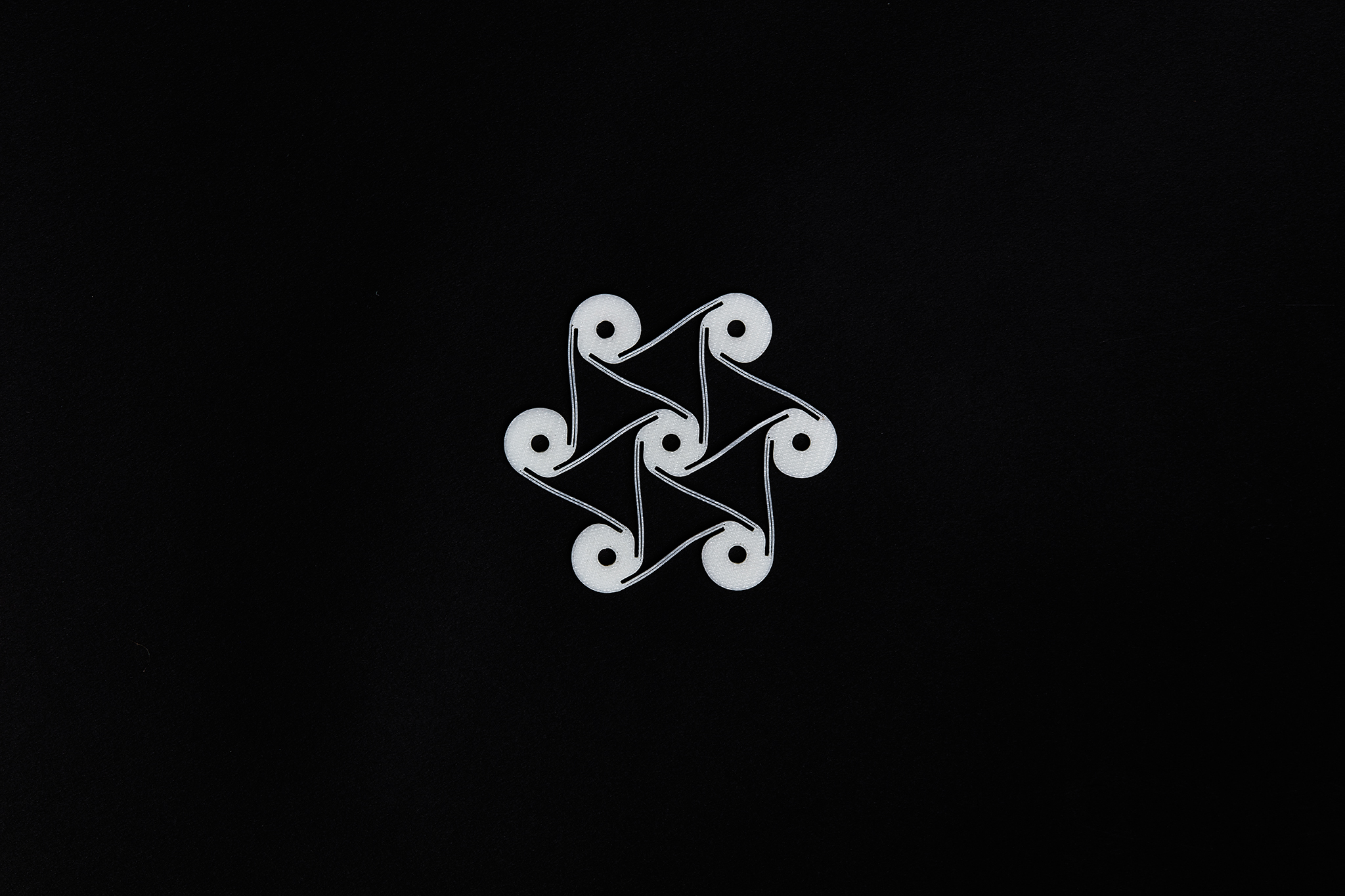

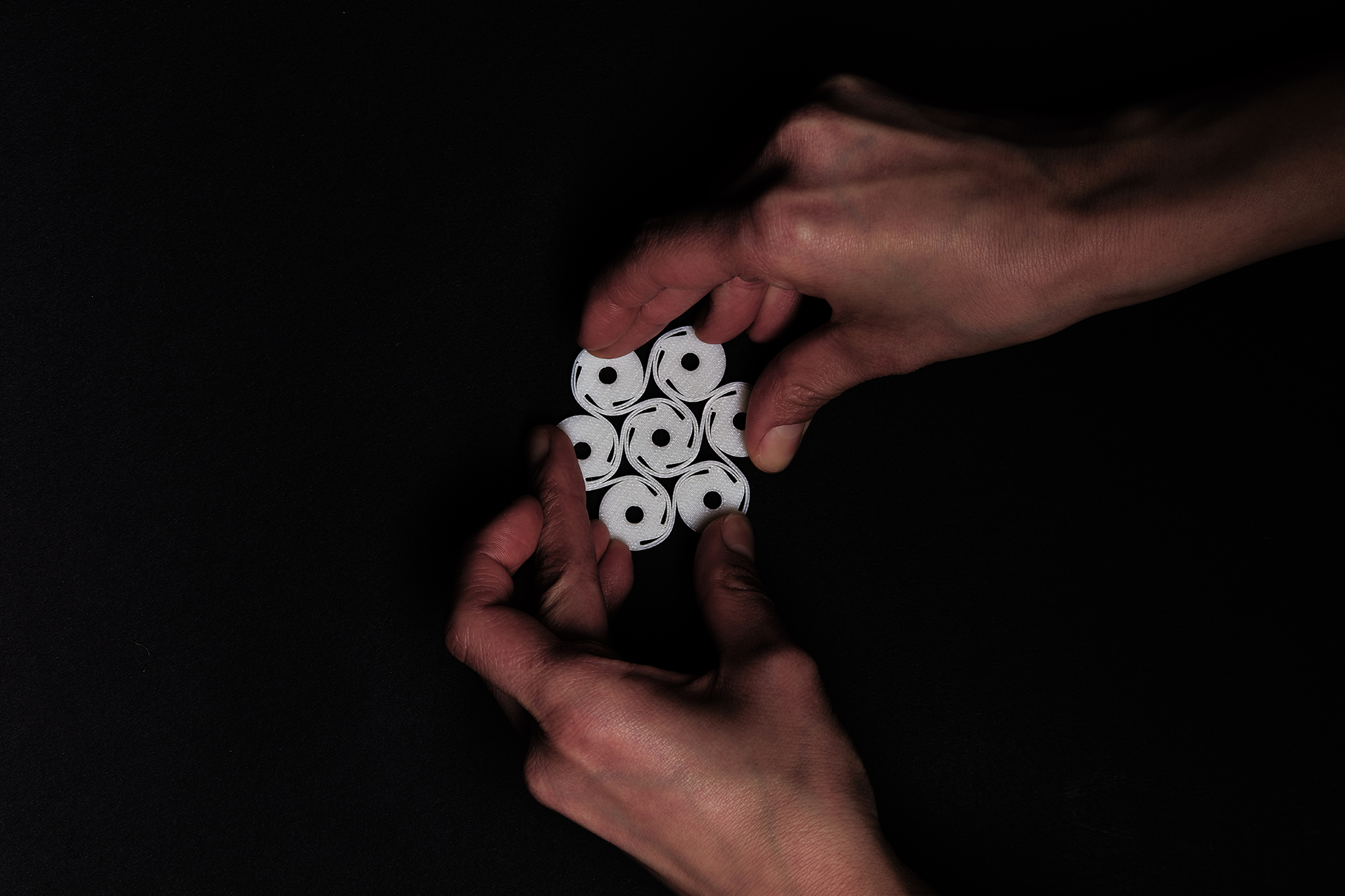

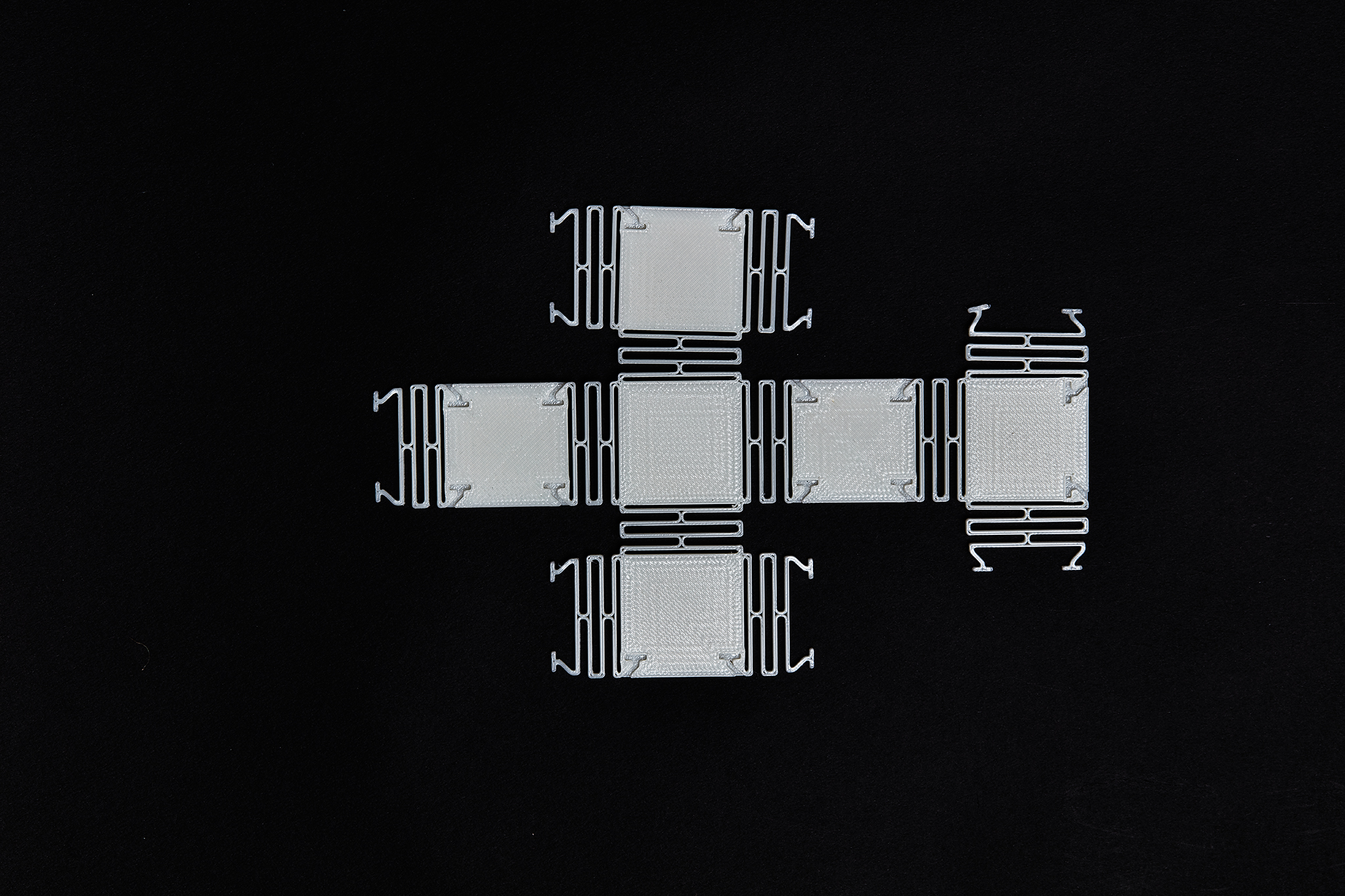

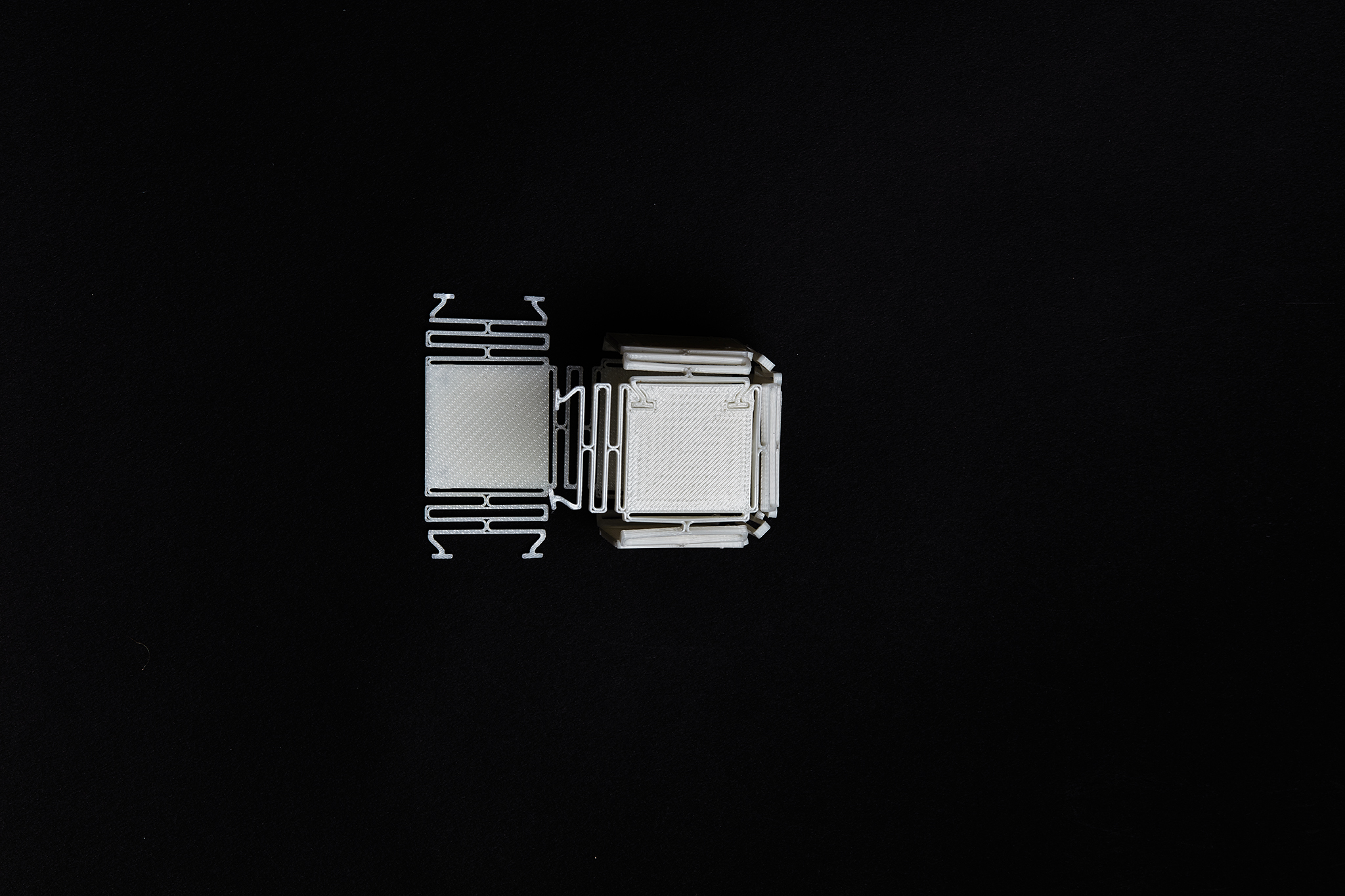

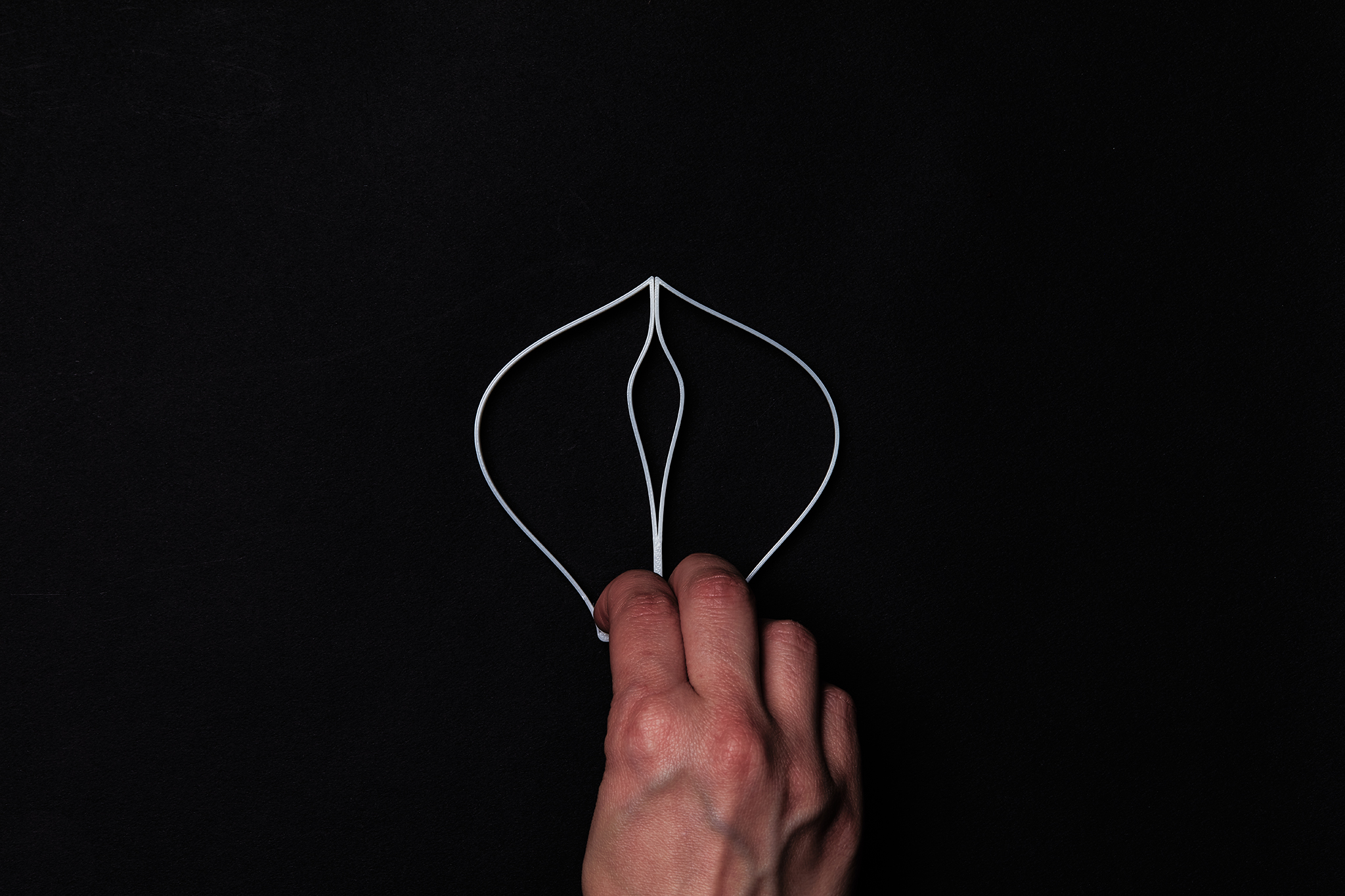

Mechanisms are found everywhere. They are small devices with high mechanical demands. Mechanisms that gain some or all of their motion through the deflection of their flexible members are classified as compliant mechanisms. This subcategory of mechanisms dispenses with the traditional joint-concept while relying on control over the material and its reversible deflection. Accordingly, the decisive component of these mechanisms is their geometry. This results in a dependency of form and function. The design of the compliant mechanism’s form alone decides on the type and quality of its function. Crucial to the behavior of these forms is their geometrical configuration. One continuous monolithic geometry emerges by omitting joints and rigid connections.

This reduces the number of components to only one, while simultaneously equipping it with a mono-material property.

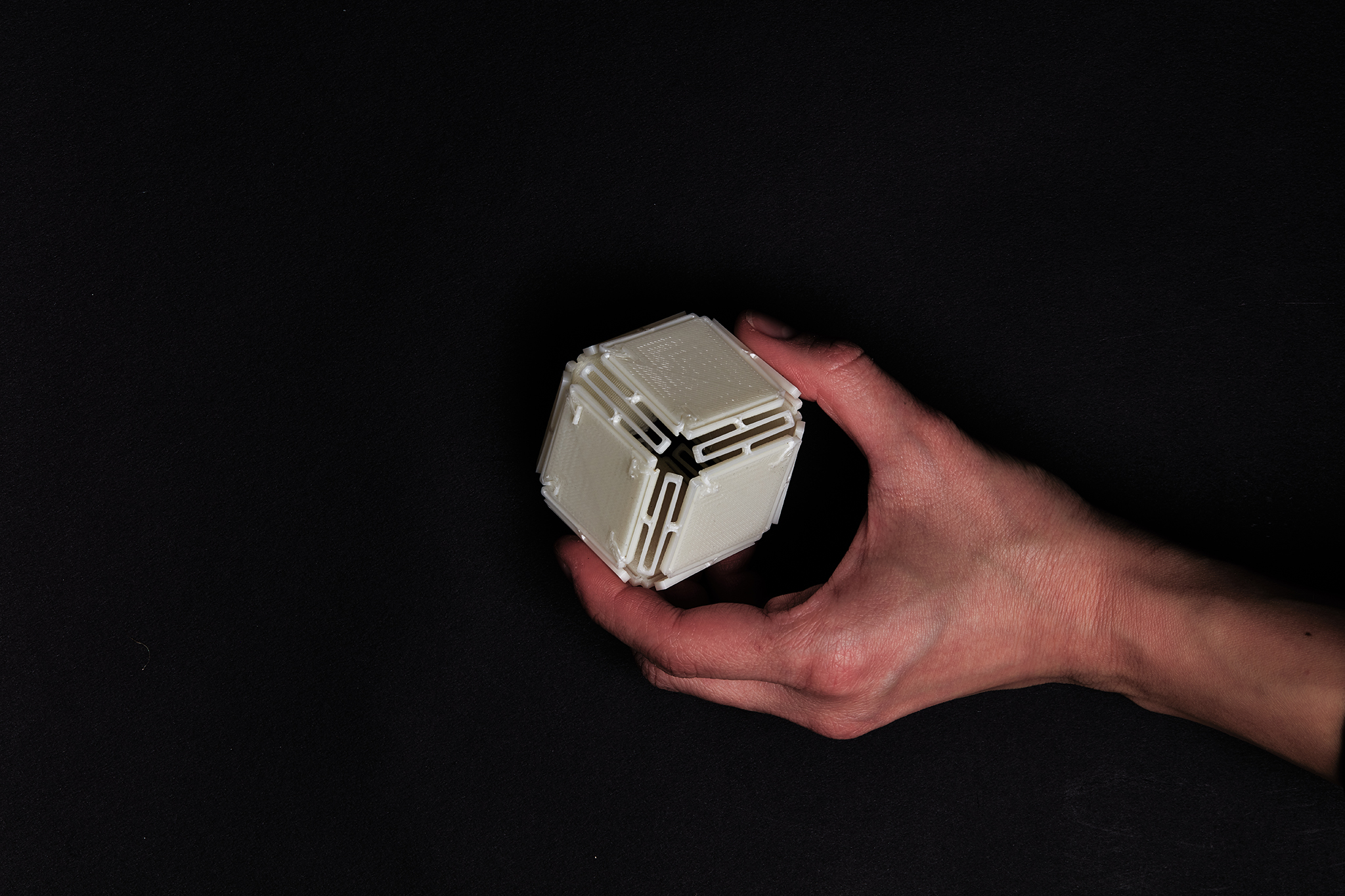

“compliance“ is a research project in the field of flexible, one-piece mechanisms, proving that the task to be performed by the traditionally constructed mechanism can be replaced by a flexible and resistant structure — a compliant mechanism. For this purpose, the designed and manufactured objects were constructed from a monolithic and continuous geometry.

Mechanisms with a compliant behavior often provide significant advantages, such as a reduction of components, simplified manufacturing, no assembly, less or no friction, less or no wear, no lubrication, high precision, compactness, miniaturization, light weight and lower costs.

By reducing the number of components to one, a globally distributed production, the subsequent shipment, the possible storage of individual elements before assembly and the assembly itself, is eliminated. Thus, the complex logistics of contemporary production would be eliminated, resulting in a reduction of the ecological footprint of these products.

Betreuer

Prof. Burkhard Schmitz, Prof. Holger Neumann, KM Antonia Kühne

Credits

Fotos: Adrian Escu