SECOND SKIN

Thanks to PCM technology, “second skin” keeps the skin within its thermal comfort zone. The t-shirts have a cooling and the sweaters a warming effect. They help reduce our dependency on heaters and air conditioners. Consequently, reducing our energy consumption indoors.

FACT:

There were two facts that fuelled our project.

• Firstly, heating and cooling account for half of the final energy consumption in buildings in the European Union. The energy demand increases during summer and winter, were people depend on indoor climate systems to keep the body cool or warm when temperatures outside reach uncomfortable levels. • Secondly, the skin temperature has an average of 33ºC — if it differs by ± 4.5ºC, the body feels discomfort.

Reducing energy consumption in buildings can aid in the transition towards more sustainable cities,which prompts the question: how can our skin temperature be regulated without depending on energy?

ACT:

Phase Change Materials (PCMs) release or absorb energy when going through a phase change. In a warm environment they melt and absorb energy, thus transmit a cooling sensation. In a cold environment, they solidify again and release the stored heat, causing a feeling of warmth. This process is infinitely reversible.

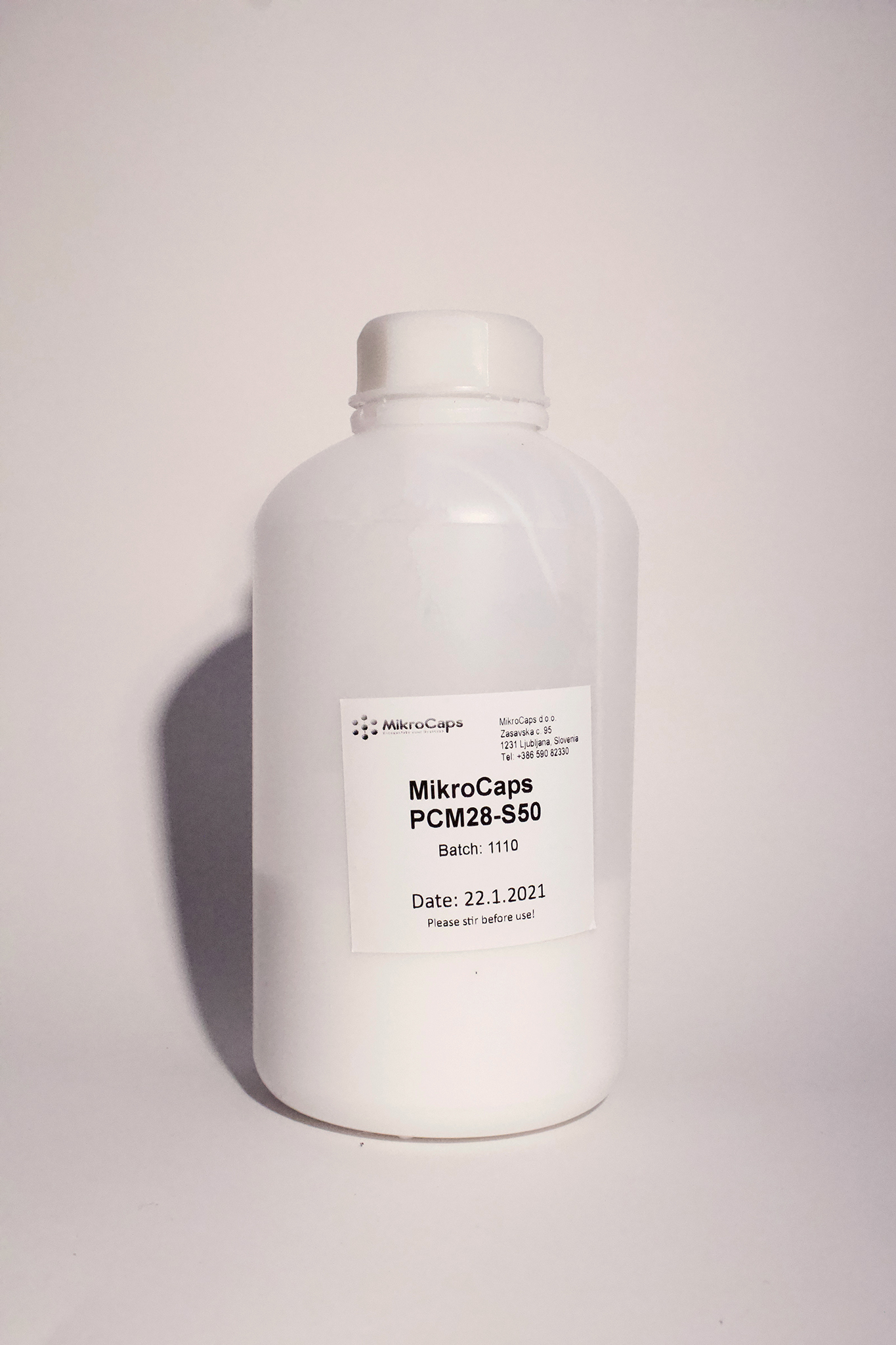

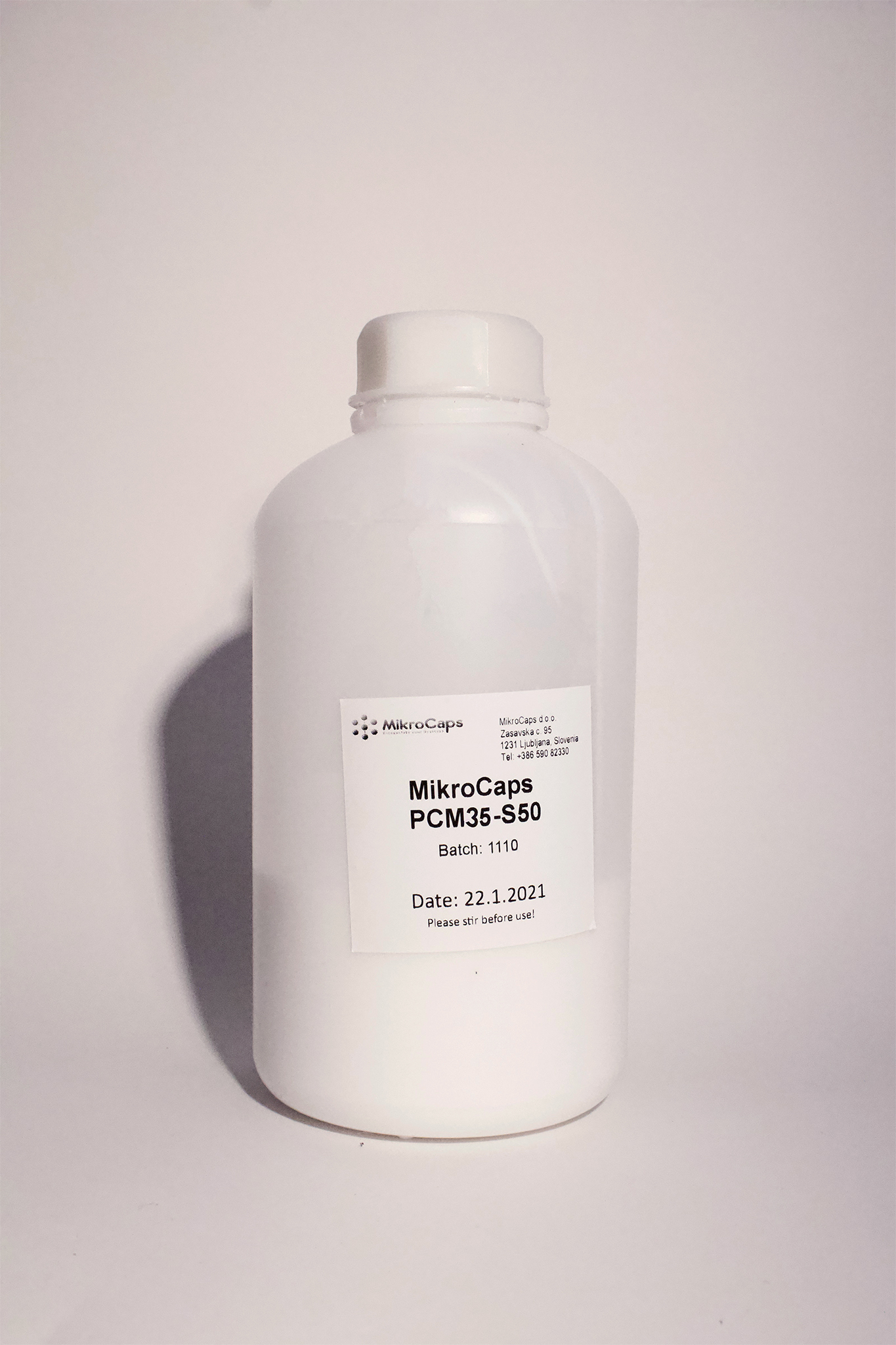

There are various types of PCMs with many different melting and solidifying temperatures. They come in a powder form or diluted in water. We chose to work with two different melting temperatures, both within the range of our skin temperature. The PCM 35 releases its warmth when the skin temperature drops below 35ºC because of cold air indoors. On the other hand a PCM 28 would melt at 28ºC or above and provide a cooling effect during summer.

The PCM has to be in close contact with the skin to be able to feel its effect. Thus we decided to make two clothing items which integrated the qualities of the material.

To be able to integrate PCMs into textiles, they have to be micro-encapsulated first, which means small, protective shells are formed around the material. Thus when the material changes of state, it remains inside the shell both in liquid and solid form. The shells also make it possible for the textile to be washed, protecting it from detergents.

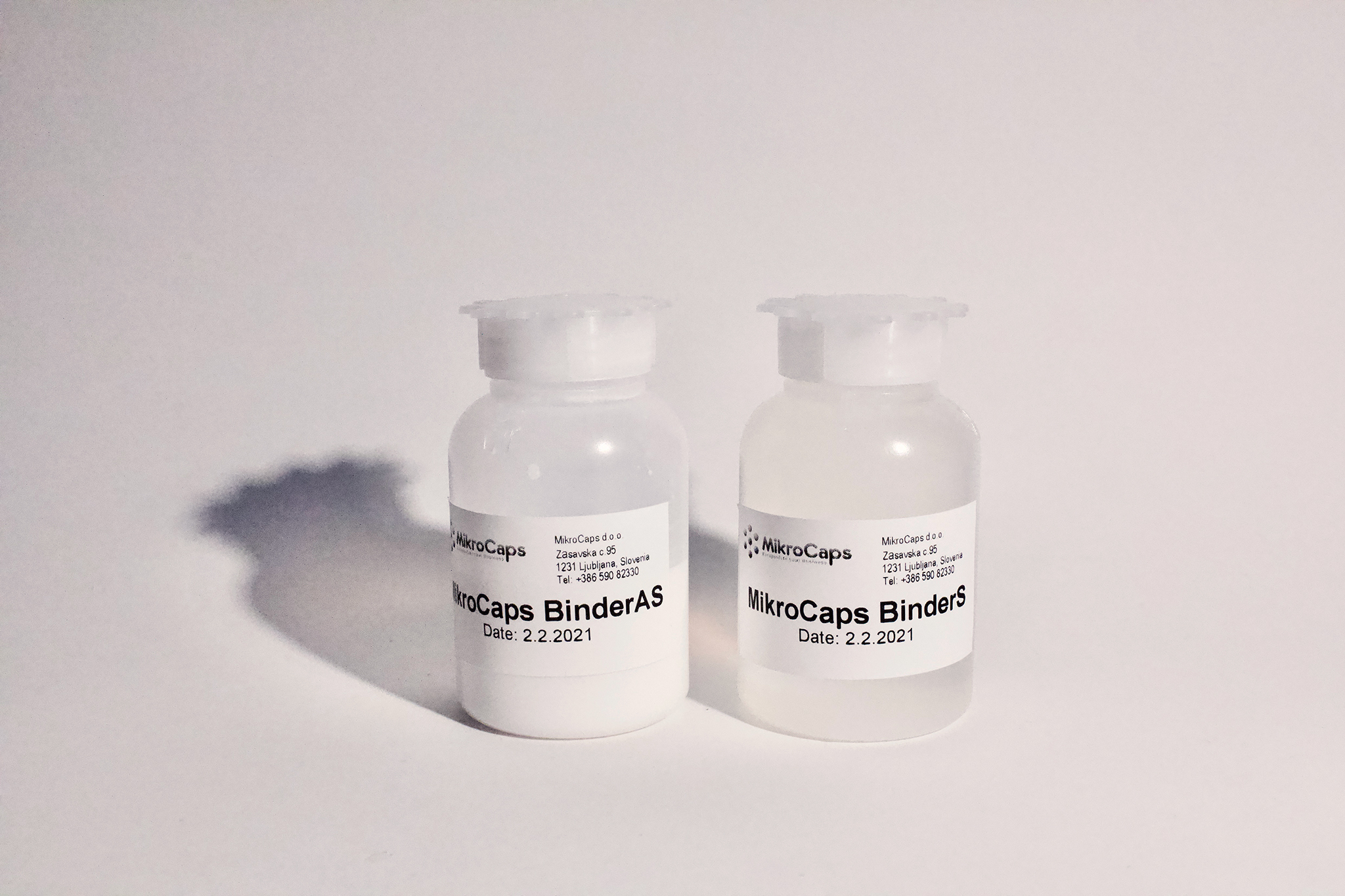

A company named Mikrocaps provided us with the micro-encapsulated PCMs and binders needed to integrate it into a textile. We made a mixture of the PCM, a binder and water. This mixture was applied to the textile using a paint roller. It was then left to dry for an hour and cured in the oven for 4min at 150ºC.

We decided to use two clothing items that are already commonly used: a t-shirt for the summer and a sweater for winter. Implementing this technology into everyday clothing items makes the material available for widespread usage. To add to the skin’s comfort, the clothes are made of soft cotton.

The t-shirts with light colours represent the cooling effect of the material within. The darker-coloured sweaters represent the warming effect.

IMPACT:

Both clothing items help keep the skin within its thermal comfort zone (29-34ºC) during temperature fluctuations. We can therefore become less dependent on heaters and air-conditioners, therefore reducing energy consumption indoors.

Katharina Sauter, 5.sem WS 2020/21

Gloriana Valverde, 3.sem WS 2020/21

Project:

PCM 35ºC – heating you up in winter

|

V

PCM 28ºC – cooling you down in summer

|

V

Process:

PCM 35ºC

PCM 28ºC