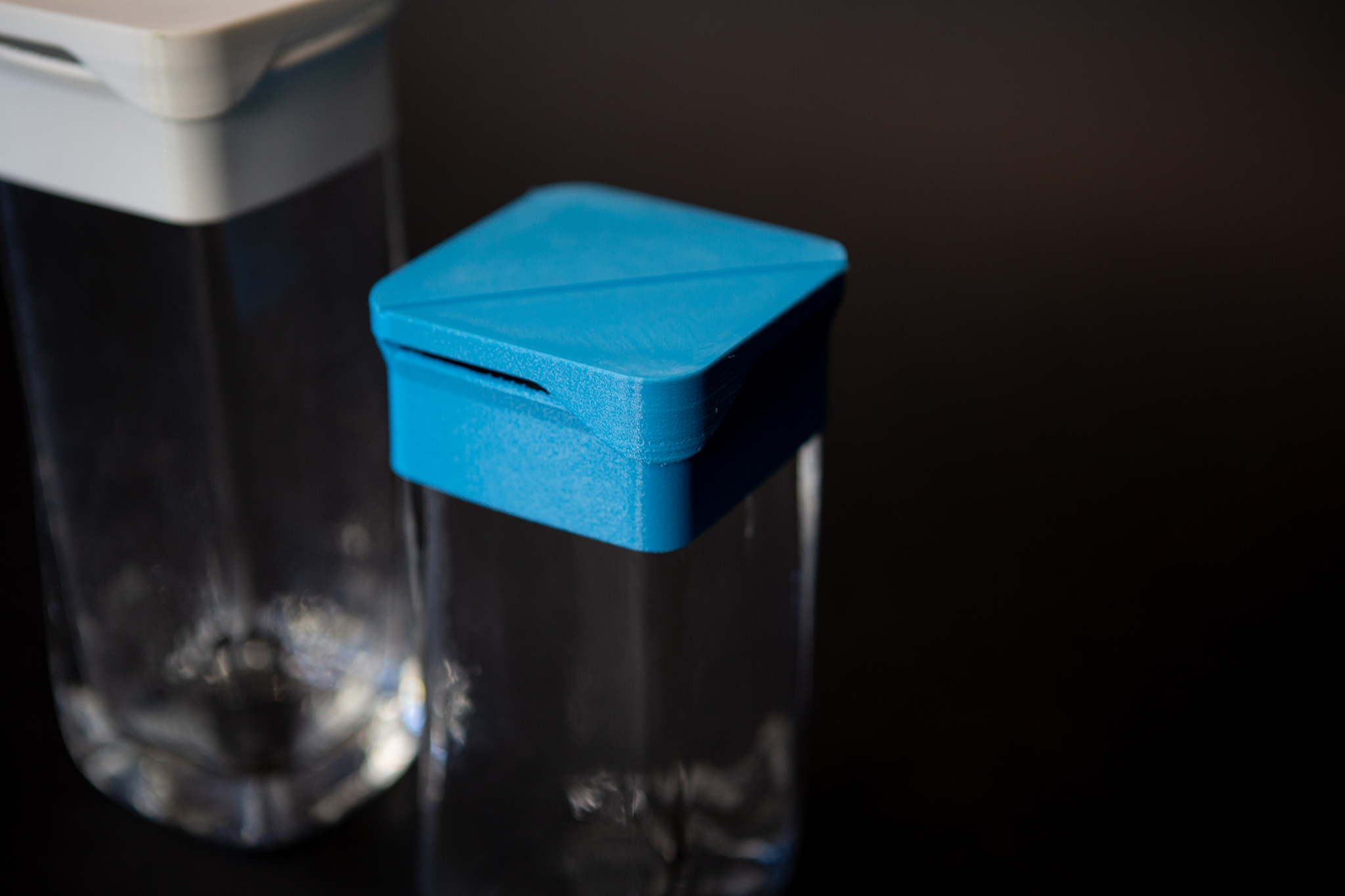

CUBO

a reusable glass bottle for dairy products

With CUBO, we have developed a reusable alternative packaging for dairy products in which the lid is firmly attached to the bottle. As a result, there is no material loss during the entire life cycle. This solves the problem that previous packaging cannot be reused in most cases. Multiple coatings and missing lids when returned make recycling impossible. CUBO combines the convenience of beverage cartons with the ecological materiality of existing deposit glass bottles.

A comparison of the life cycle assessments of different beverage containers shows that, in terms of sustainability, returnable deposit systems and tetrapaks are at the top of the list. Nevertheless, there are many problems that stand in the way of them being 100 percent sustainable. The commercially available beverage carton is not only made of paper but is usually coated with aluminum and plastic. In addition, the twist cap, which most of those products have, is also made of plastic. Overall, the company tetrapak itself, produces about 700,000 tons of plastic per year. Thus, the recycling of this packaging is difficult and is therefore not usually done. Only 33 percent getting recycled. In addition, most of them are thrown into the wrong garbage and thus cannot even be disposed of correctly. The situation is much better with reusable deposit systems. But here, too, the reusable cycle can usually not be completed because of-ten the lids, which are made of sheet metal and are also often coated with plastic, are either not returned or are too difficult to recycle. Both beverage cartons and conventional glass bottles therefore consist of several materials whose separation in the recycling process is not possible or too expensive.

Our goal with CUBO was to design a 100 percent returnable alternative to beverage carton and glass bottles. CUBO is a reusable alternative with the lid firmly attached to the bottle itself. This guarantees that no waste is generated during its entire life cycle. Industrially, on the other hand, the lid can be easily removed for cleaning and filling. It combines the convenience of beverage cartons with the ecological materiality of existing deposit glass bottles. Due to the under-cut-free shape, industrial cleaning of the bottle can be carried out in a much more resource-friendly manner than with conventional glass bottles. The lid can be opened completely in half. Thus, any contents can be poured out comfortably. Food products such as viscous dairy products like yogurt can also be conveniently completely consumed due to the omission of undercuts. In addition, the glass form can be produced more easily, since it is completely open on the top. Another problem with the handling of glass bottles is the lip of the spout. When pouring slowly, the contents usually drip down the neck of the bottle. To protect the glass from breaking, it must be strongly rounded. However, in our design, the edge of the glass is protected by the plastic cap all around, so we can use a sharp edge. Thus, CUBO represents a completely ecological alternative to conventional beverage containers.

Anton Oberländer 3 Sem. WS 2021/22 |

Luca Ortmann, 3 Sem. WS 2021/22 |

project:

process: