In crisis situations, particularly in developing countries, logistical challenges hinder the timely delivery of essential emergency aid. This is where 3D printing becomes a critical solution, enabling the on-site production of critical items and spare parts. The Formlabs Form 3 stands out in these scenarios with its intuitive interface and versatile resin capabilities, ensuring reliable production under demanding conditions. This is complemented by an emergency kit, which includes a durable aluminium box that serves as both a robust housing for the printer and a functional working platform, adaptable to unstable power sources. This setup, integrated with a Red Cross-inspired platform for accessible 3D files, enhances the Form 3’s role in improving the efficiency and reliability of emergency response operations.

Project:

Usually when a disaster occurs, it hits people in developing nations the hardest. The transportation of necessary emergency aid to places that no longer have access to general supplies is complicated. Often there is a partial or complete lack of a functioning logistics infrastructure. Emergency and relief operations become even more challenging, especially since the goods are extremely time-critical. Help can even come to a halt when appliances break down and the necessary spare parts take days or even weeks to be delivered. A solution is needed to produce goods.

In those critical moments, 3D printing can offer an answer for creating products and spare parts on the ground. It can create a lifeline, producing medical supplies and equipment on demand. However, 3D printing can be a challenge in these high-pressure situations.

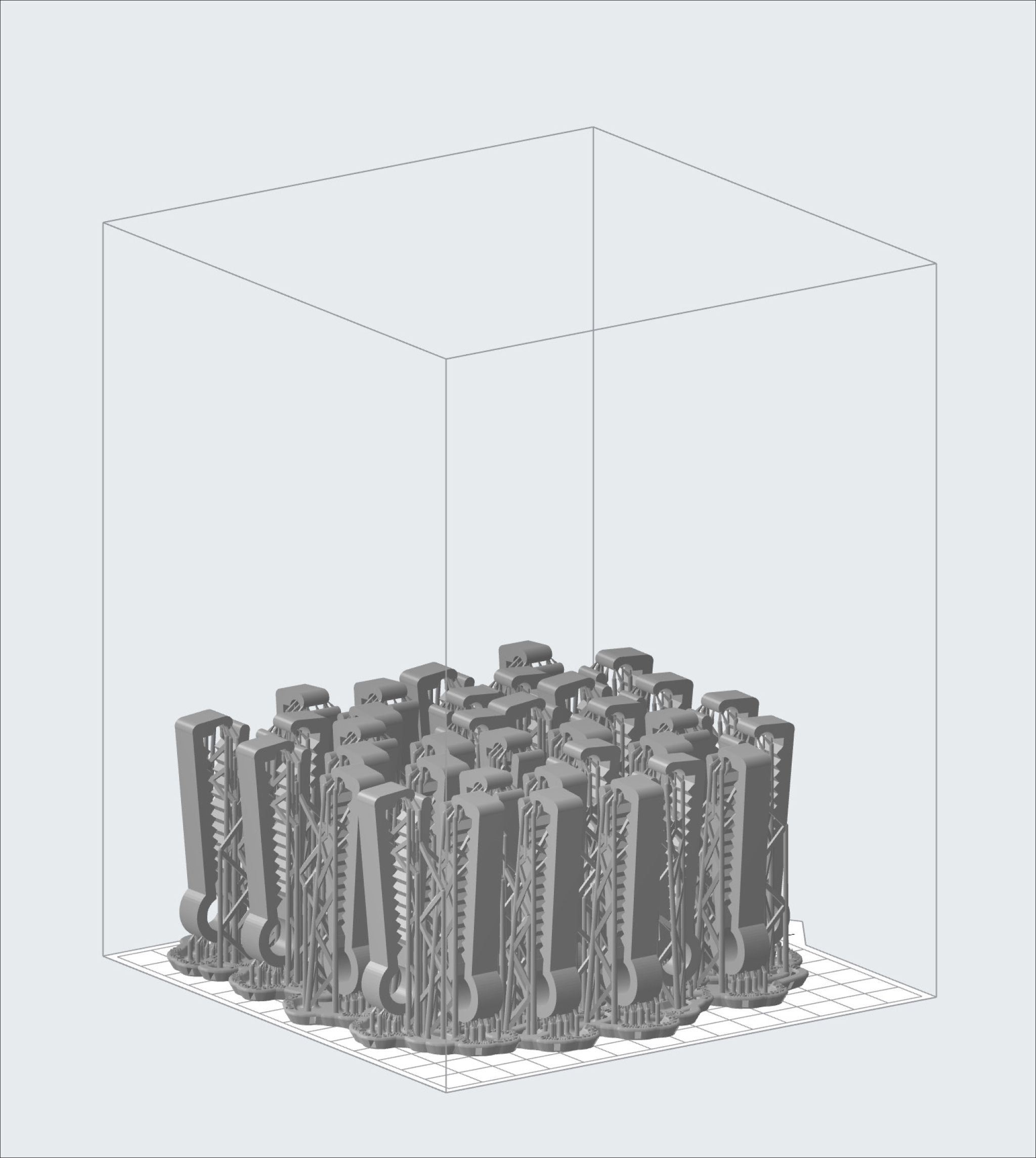

That’s where the Formlabs Form 3 can make a difference. With its user-friendly interface and various quality resins, the Form 3 can produce a broad range of parts and products. Its ease of use and consistent output make it a reliable choice in demanding scenarios. But there are also practical issues, such as access to the right 3D files or the appropriate working environment for the printer.

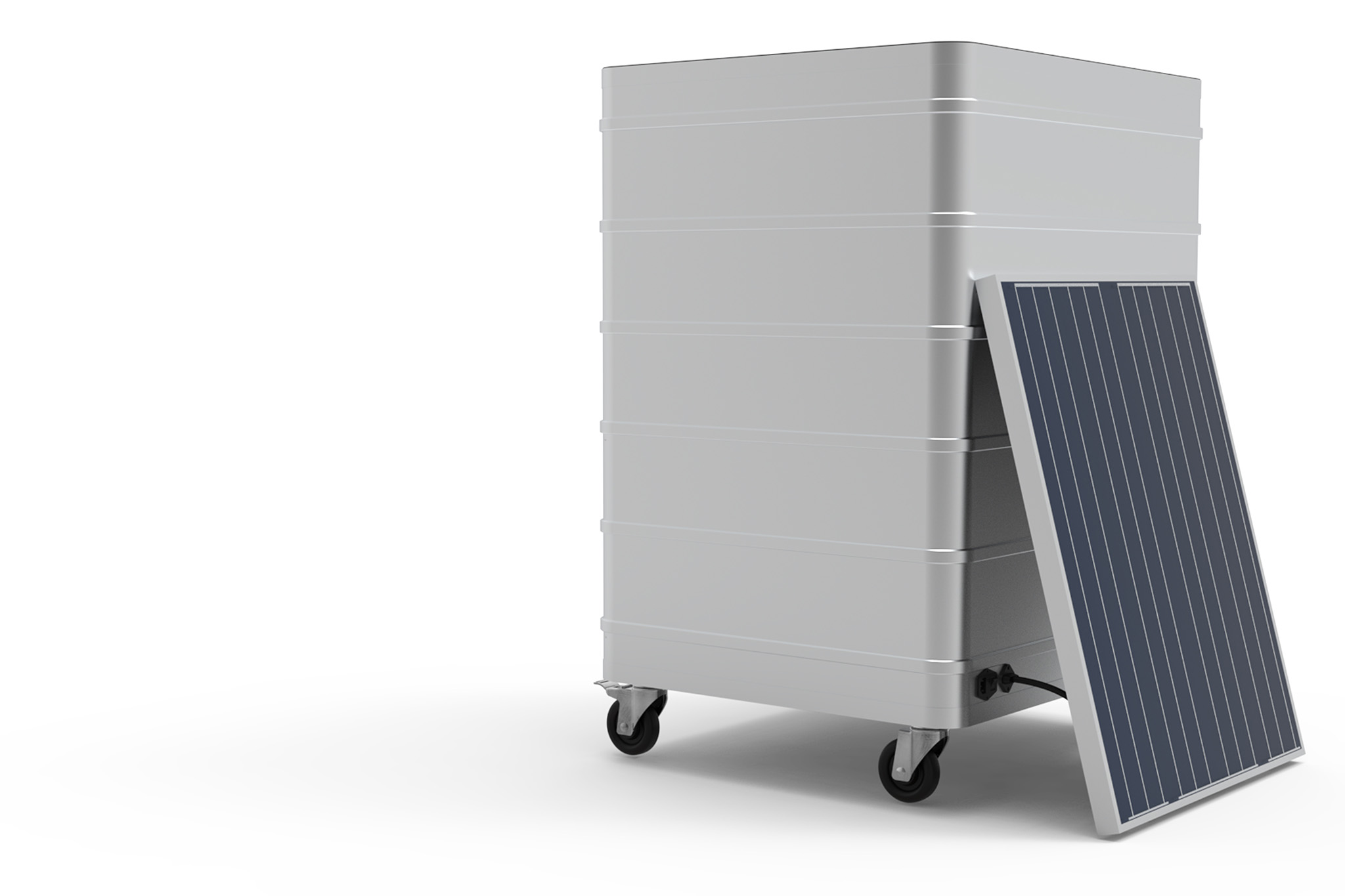

This is where the new emergency package comes in play, developed by working closely with various stakeholders to simplify on-site printing. A robust aluminium box, standard in international logistics, doubles as a dust and shock-proof housing and a work platform for post-processing, with a construction that facilitates the necessary levelling for the printer’s operation. The box accommodates both the printer and the wash & cure process, as well as all the necessary materials. Industrial pull-out drawers allow easy accessibility. Often located on unstable power grids, unreliable for 3D printing, a generous power bank not only provides the necessary security, but also allows solar panels to be connected.

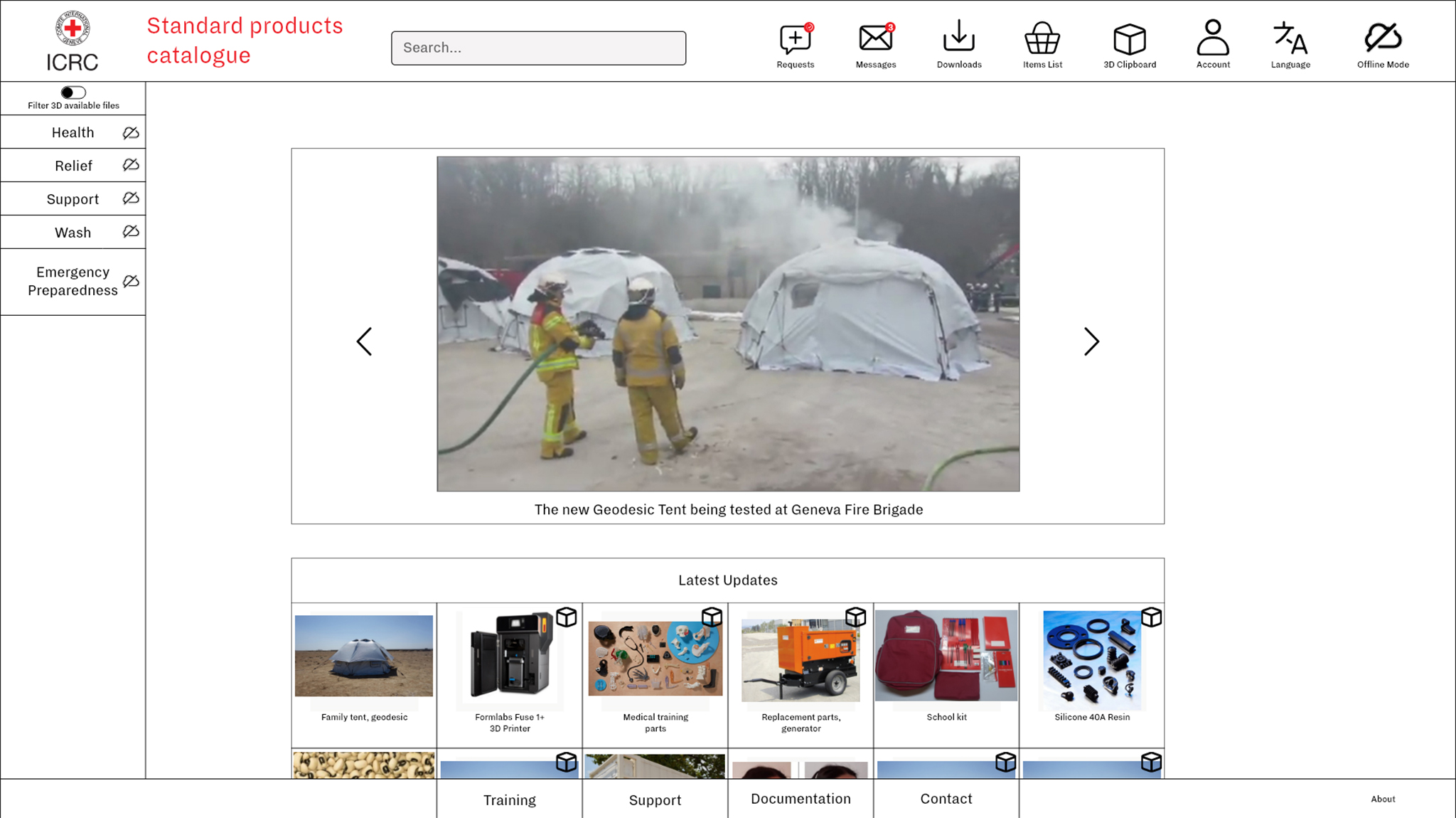

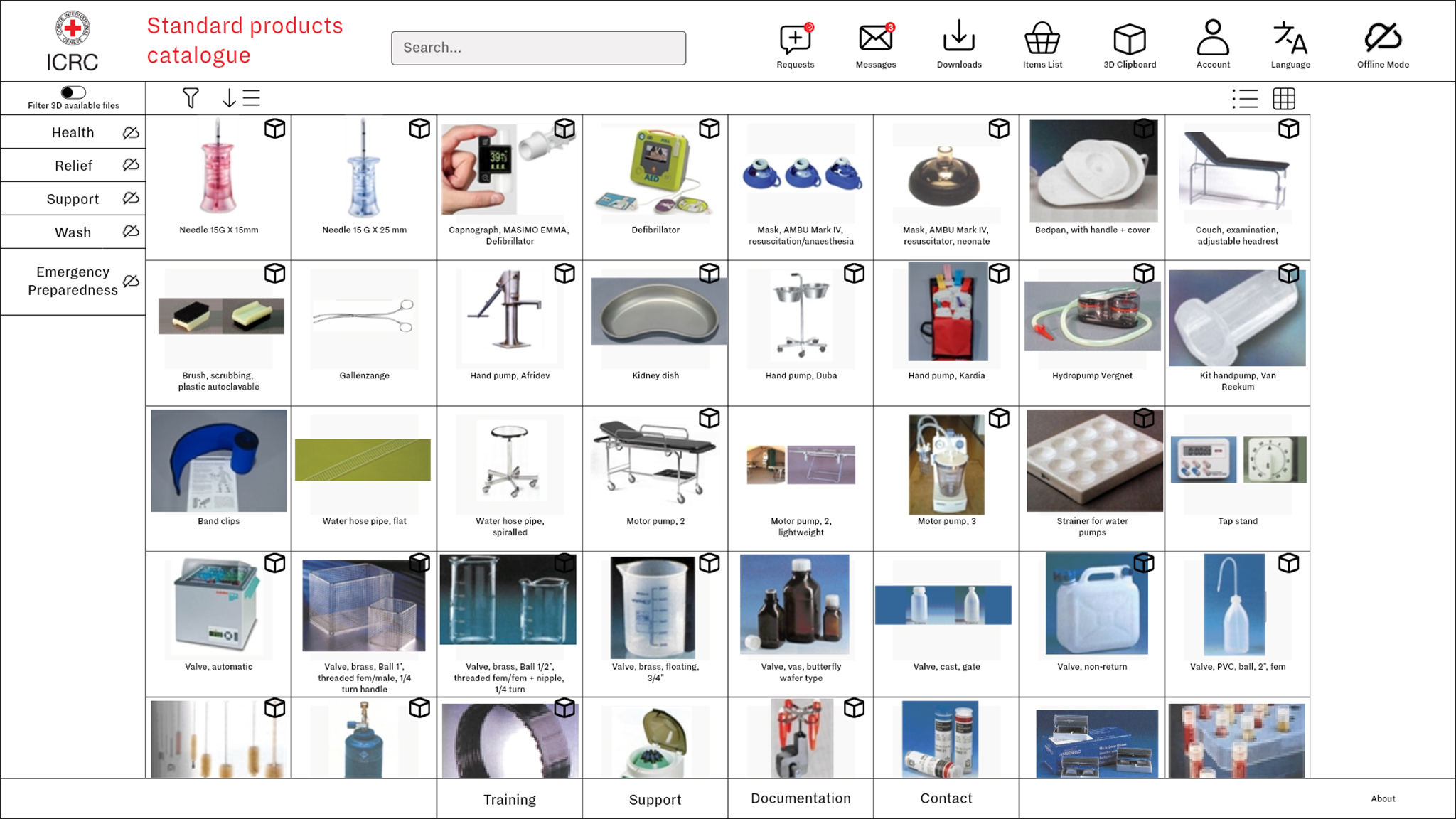

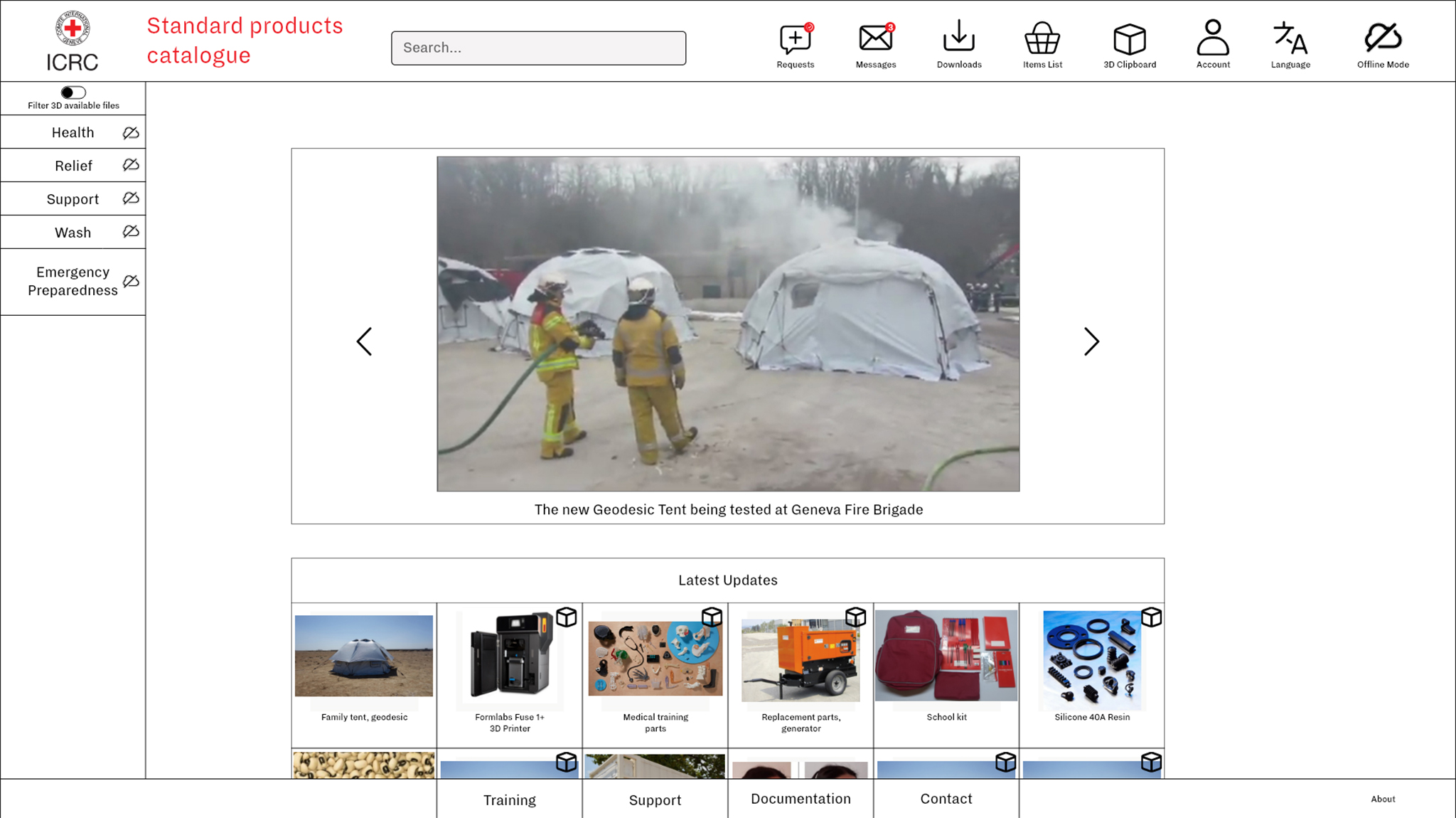

A platform based on the Red Cross Standard Product Catalogue, which lists all the products needed for crisis relief, has been developed to provide local users with access to 3D files and much more. Through the NGOs‘ headquarters, engineers and designers work on expanding, optimising and modifying these 3D files in direct exchange with the workers on site.

The Form 3 helps to avoid supply bottlenecks in international emergency aid and by that creates a more resilient system. Through a network of various actors, an increasingly solid database is being created that can be downloaded to be there in an emergency.

Process: