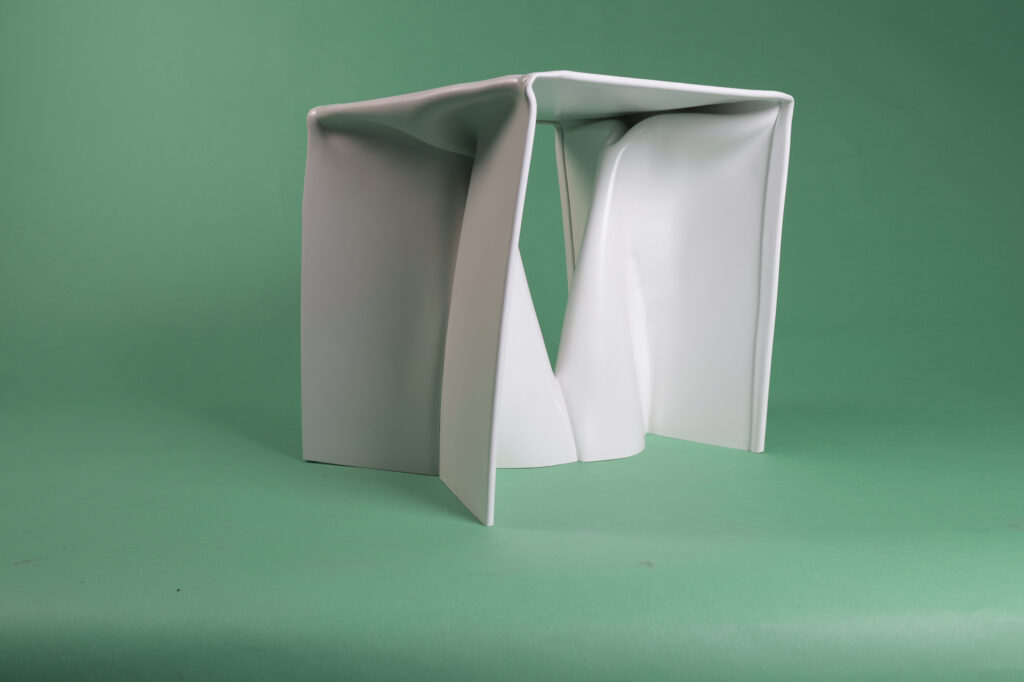

This side table is made from a single 4 mm PS sheet, heat-folded by hand using only simple tools: a heat gun, clamps, and bending guides. The flat pattern (1.4m × 1 m) was cut from a standard 2 × 1 m sheet, then locally heated and shaped with folds. Structural stability is achieved through folding and interlocking geometry. No screws, glue or other materials are used. The concept explores resource-conscious production using recyclable monomaterials and minimal infrastructure. While made from PS, the method applies to any low-melting thermoplastic. It’s a proposal for accessible, low-impact manufacturing: efficient in material, simple in process, and easy to recycle.

The project:

The process: