BAYAS

A packaging and transport system for soft fruit

We aimed to reduce plastic dependency in the packaging industry by designing a berry tray made of paper pulp, which is easily moldable. We were inspired by the geometry of the egg-carton, which implements dents that give rigidness to the form. BAYAS implements a new way of transporting these trays: instead of using boxes, we designed a grid-template, which uses less cardboard. The trays fit into the dents of the grid, allowing a safe transport

During the implementation of our project, we identified and contextualized the problem of consumption in the supermarket. In particular, we looked at the amount of waste and material consumption for transport packaging (such as cardboard boxes, which are produced in large quantities and thrown away after use) and packaging (which is mostly plastic). These plastic packaging materials not only have advantages such as less weight, transparency, flexibility and cheap production, but also have huge social and environmental impacts, as they have been produced in a drastic amount of 8.6 billion tons since 1950, of which only 9% have been recycled. Although there are recycling systems for this material, almost half of the collected material ends up in waste incineration, which causes high emissions of toxic gases.

On the side of producing cardboard boxes in quantities for transportation, the problem of resource and energy consumption for the production of these boxes and their immediate disposal (which often takes place in supermarkets) becomes obvious.

Since we wanted to focus our project on products packaged in plastic, where plastic is also used as a means of transportation, we came up with fruits and vegetables. In this context, we saw the challenge of redesigning the packaging of berries, because plastic is still commonly used for fruits that are sensitive to external damage. Therefore, we decided to look at sustainable production alternatives for packaging that avoid the use of plastic. One of these alternatives is the production of materials from recycled paper fibers and water. This material is not only considered sustainable compared to plastic, but it is also easy to shape, durable due to the binding of compressed paper fibers, and has low production costs.

For this packaging, we made sure to create a geometry that provides stability and security for the contents by adding dimples in the walls and a rim that allows for better handling. In addition, when we redesigned the berry packaging, we came up with the idea of a new type of transport box that is reduced to a grid template and made from recycled cardboard.

This grid weighs only half as much as a cardboard box used for transporting berries, and allows for easy locking of the package by means of intersecting crosses, which makes it almost impossible to shift it unintentionally when transporting the berry package. The grid also covers the contents during transport, so there is no need to put a lid on the container. The semi-cylindrical geometry of the container facilitates handling during transport.

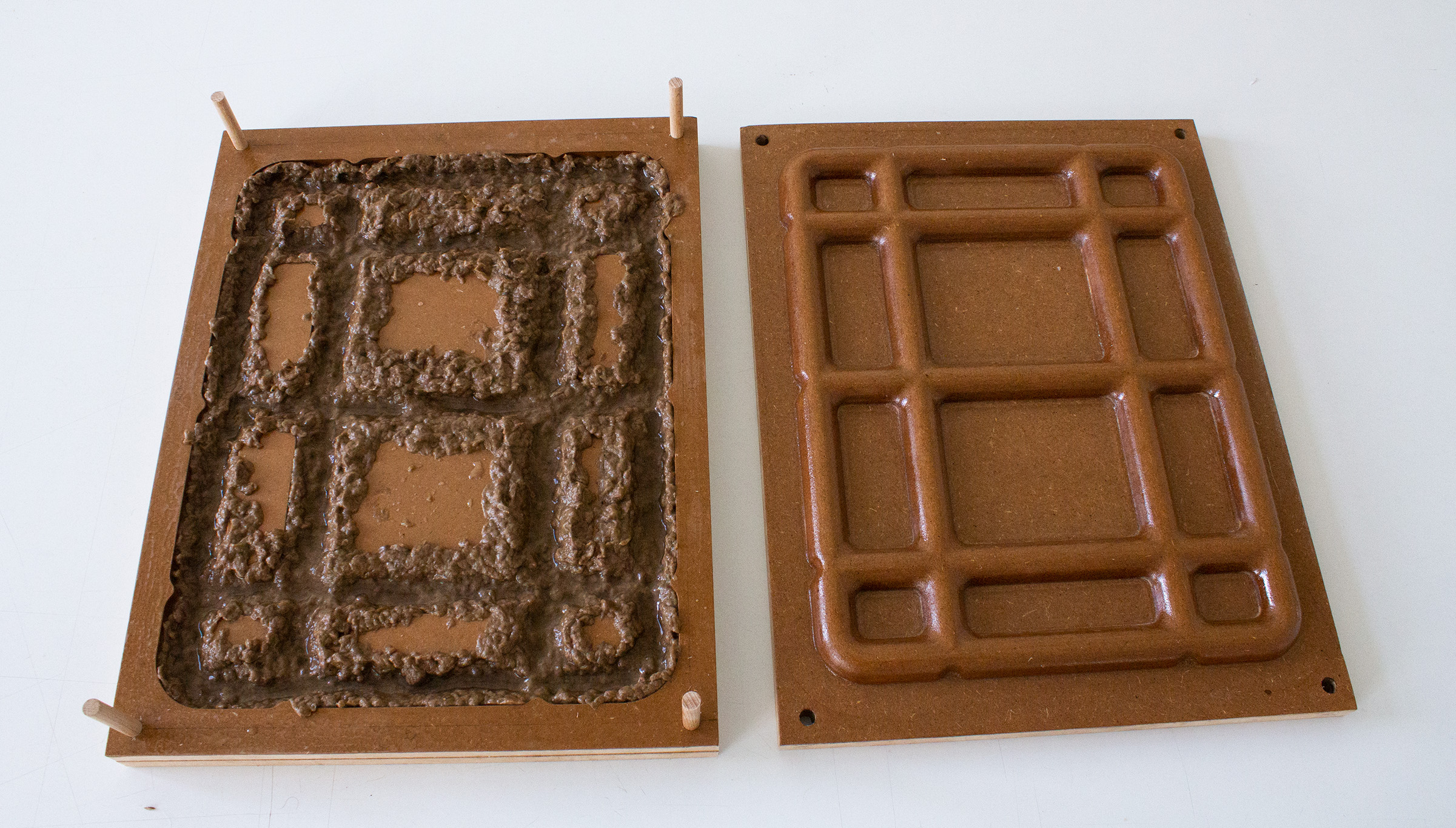

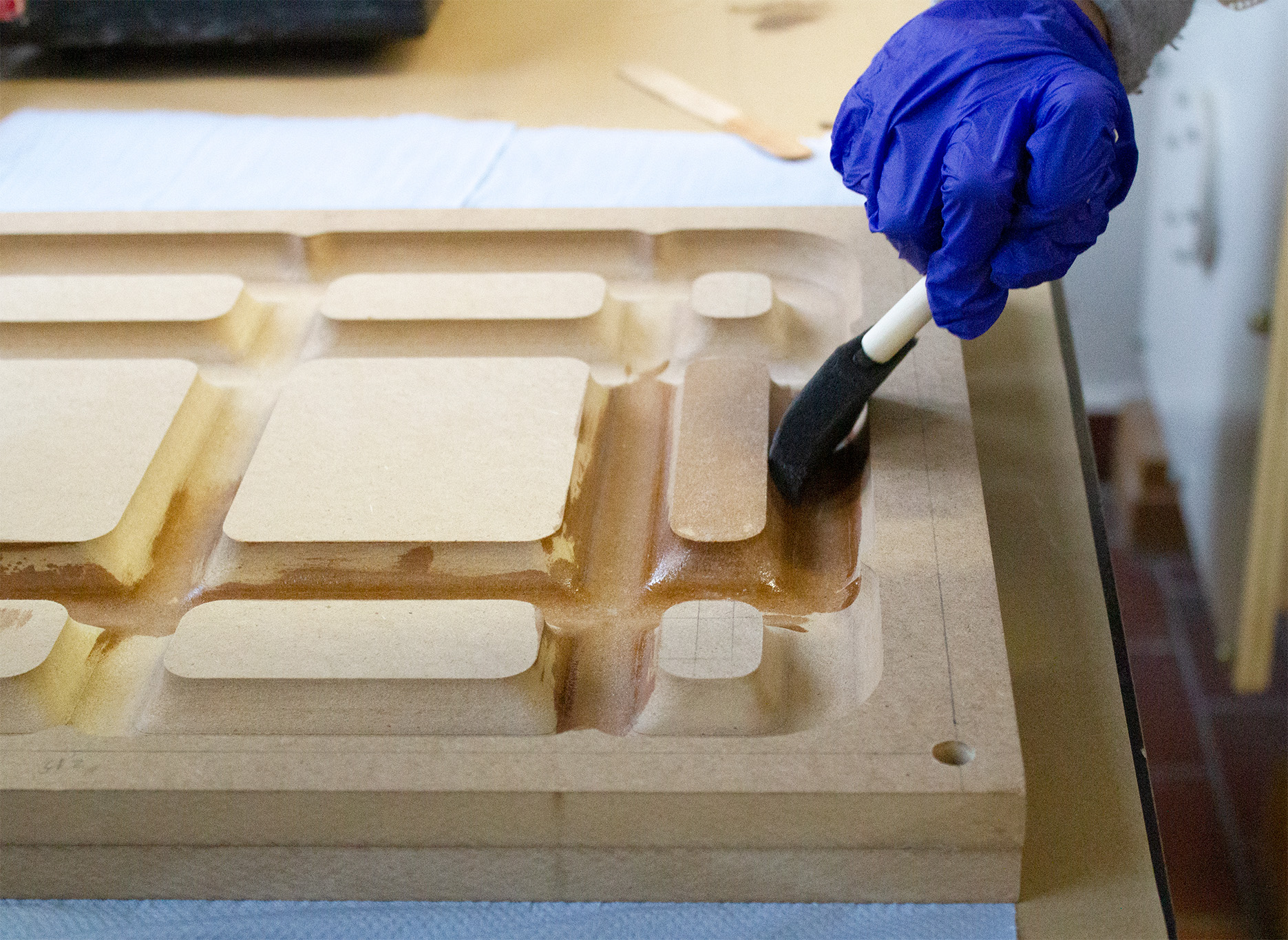

For the production of the two elements, we have designed two corresponding molds (one negative and one positive) that correspond to the actual industrial pulp molding process. For this process, we use a mixture of paper pulp, recycled cardboard and water. When preparing the mixture, we add salt to prevent mold formation when in contact with moisture.

Maria Salamanca Millán, 3 Sem. WS 2021/22 –

Gloriana Valverde, 5. Sem WS 2021/22 – g

project:

process: