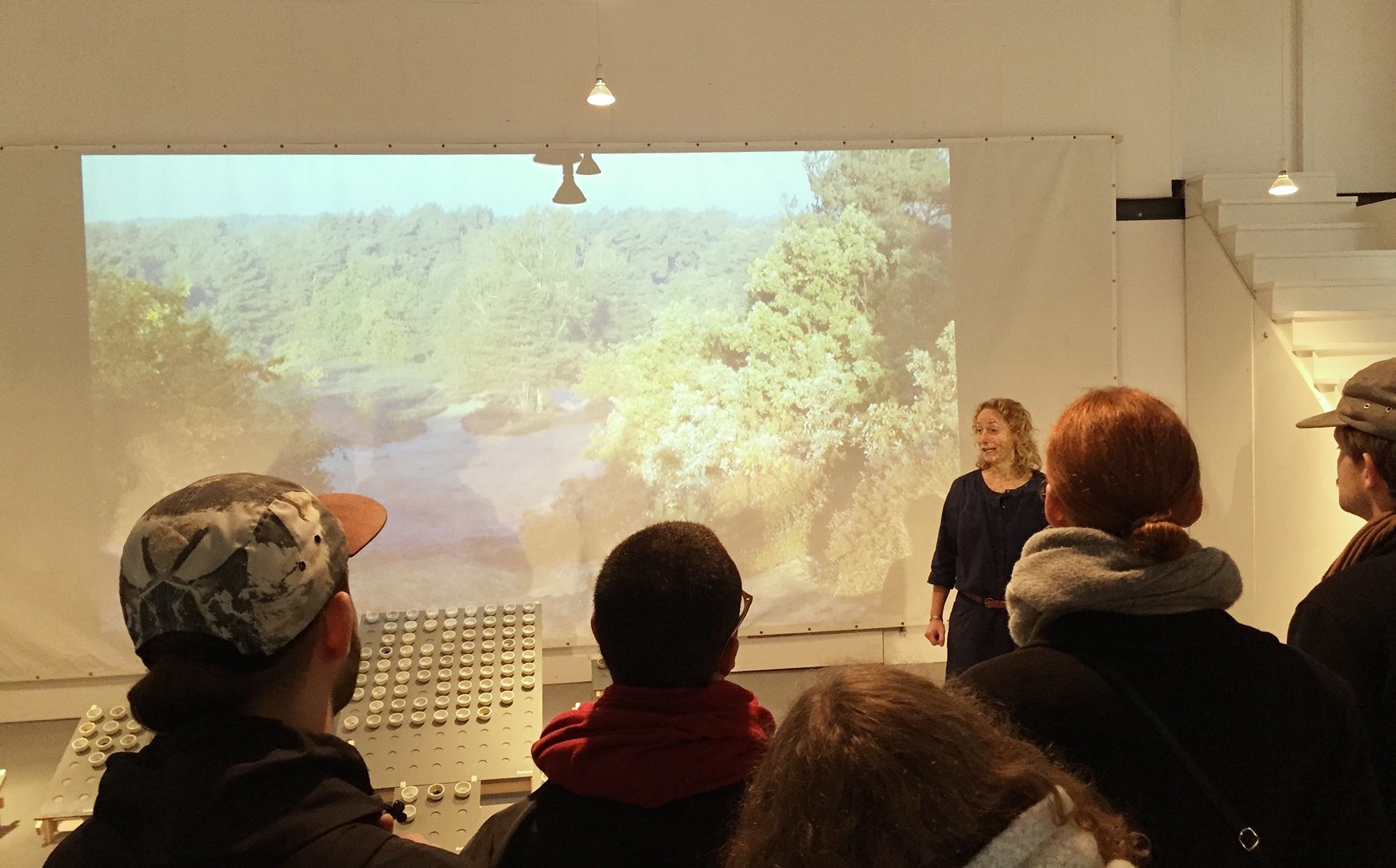

For UdK’s Rundgang 2018 designtransfer shows the exhibition ONE YEAR DESIGN & SOCIAL CONTEXT which shows three projects that Product Design Professor Ineke Hans realised with students in her first year at UdK Berlin.

It concerns a.o. two recent projects from Summer Semester:

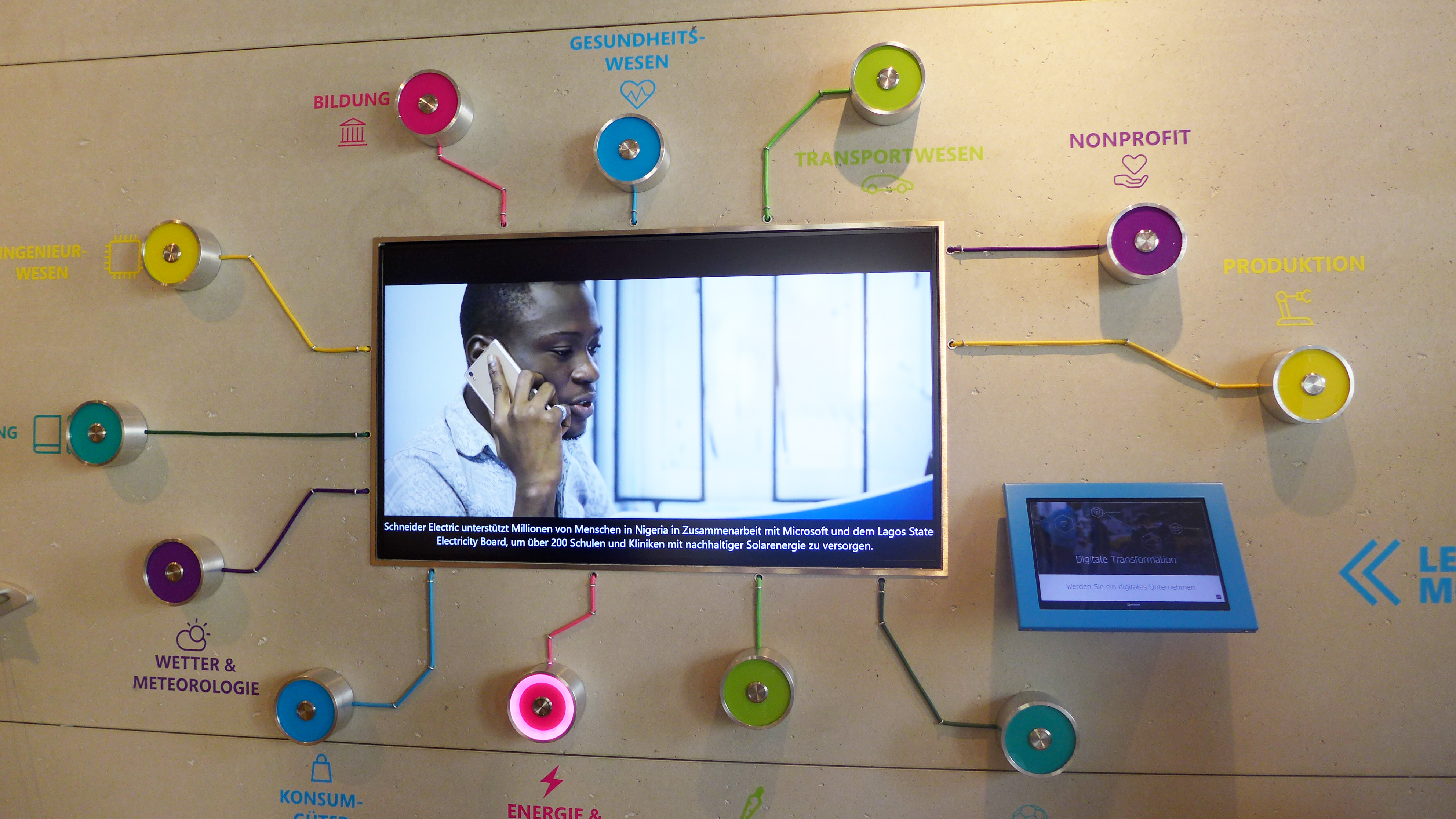

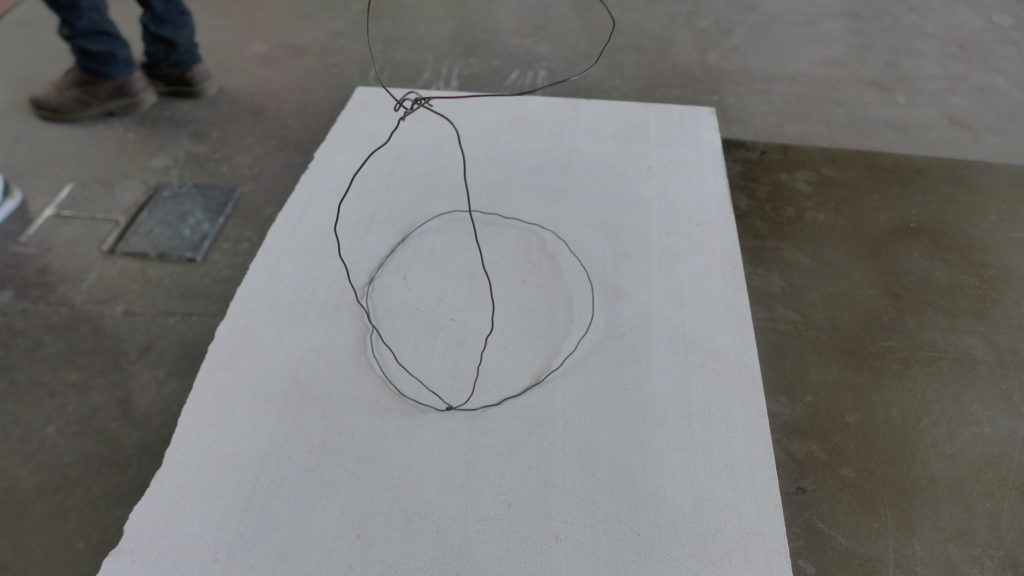

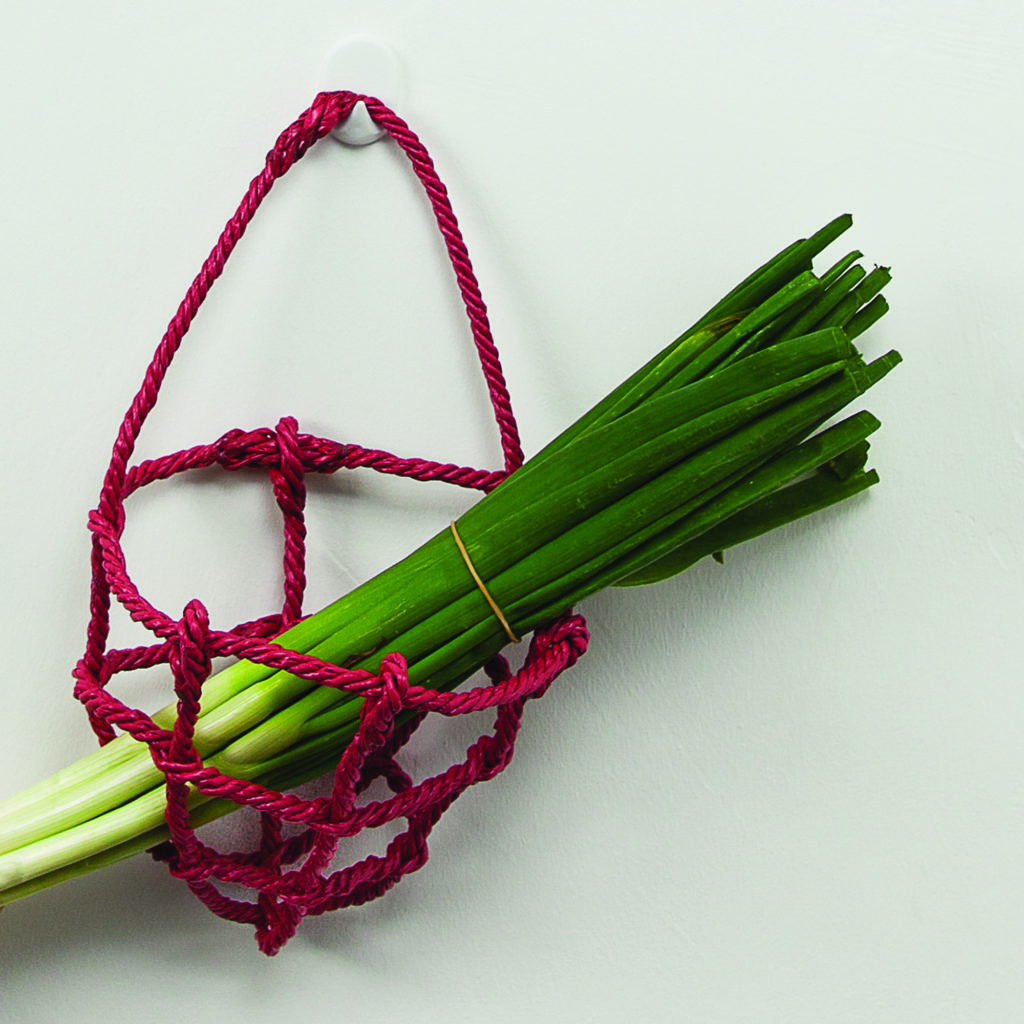

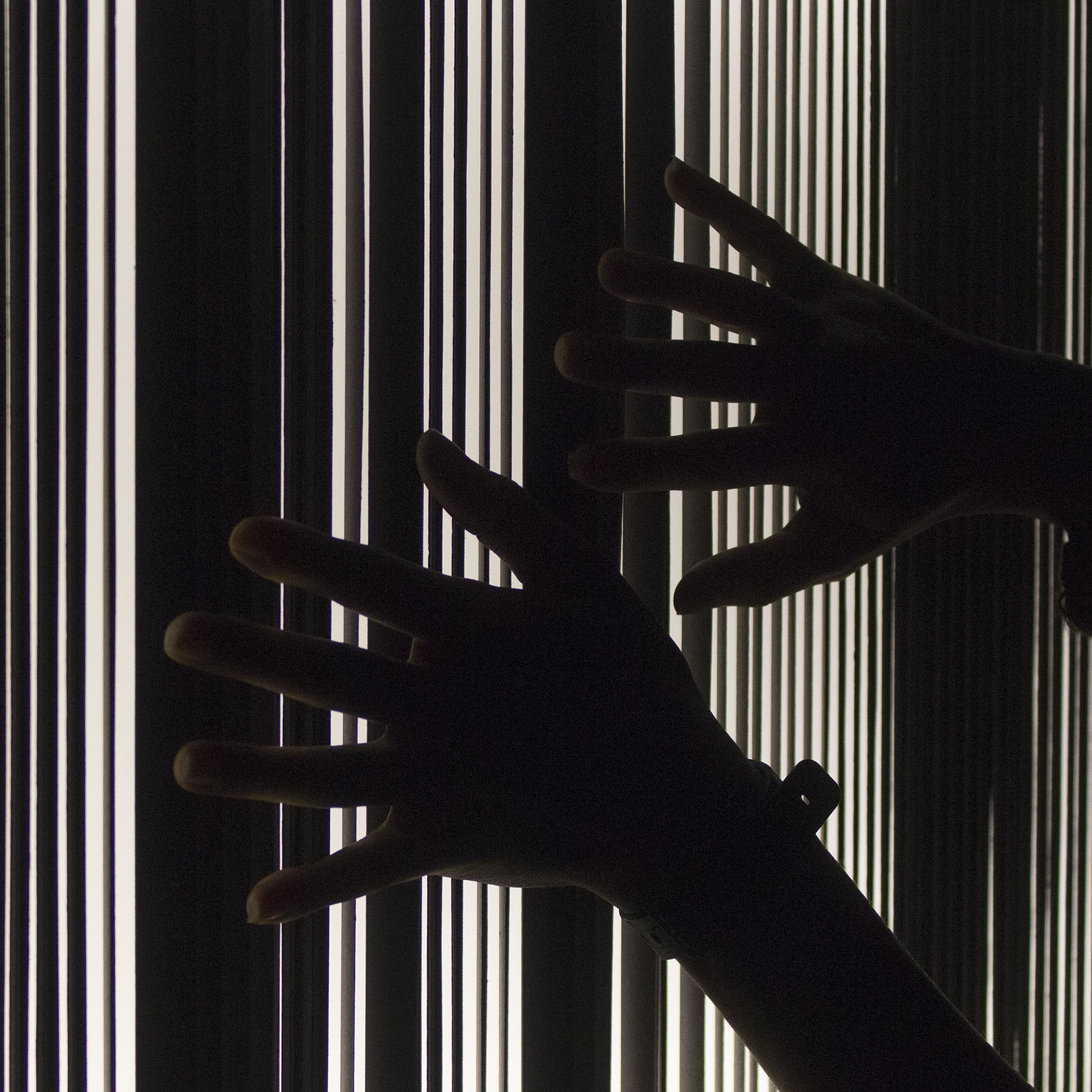

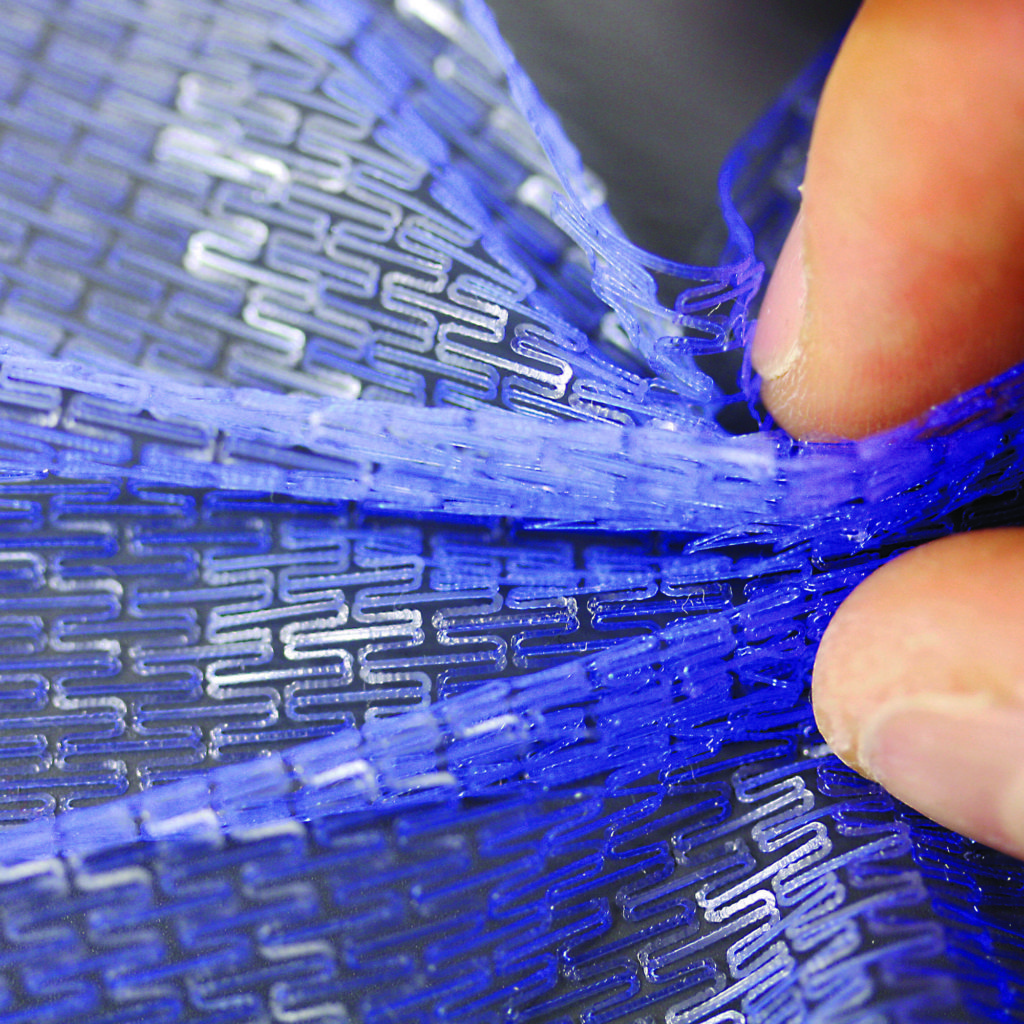

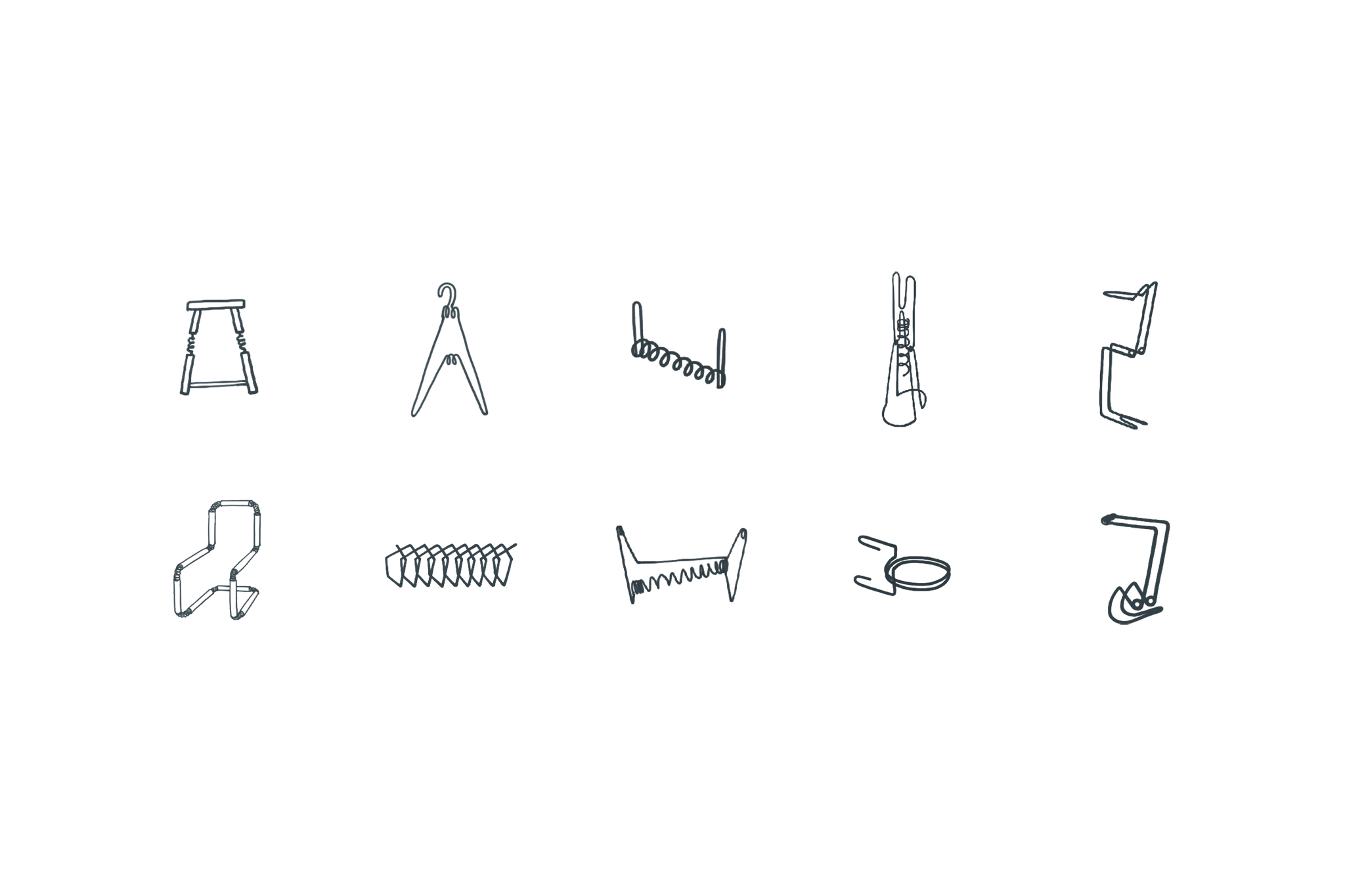

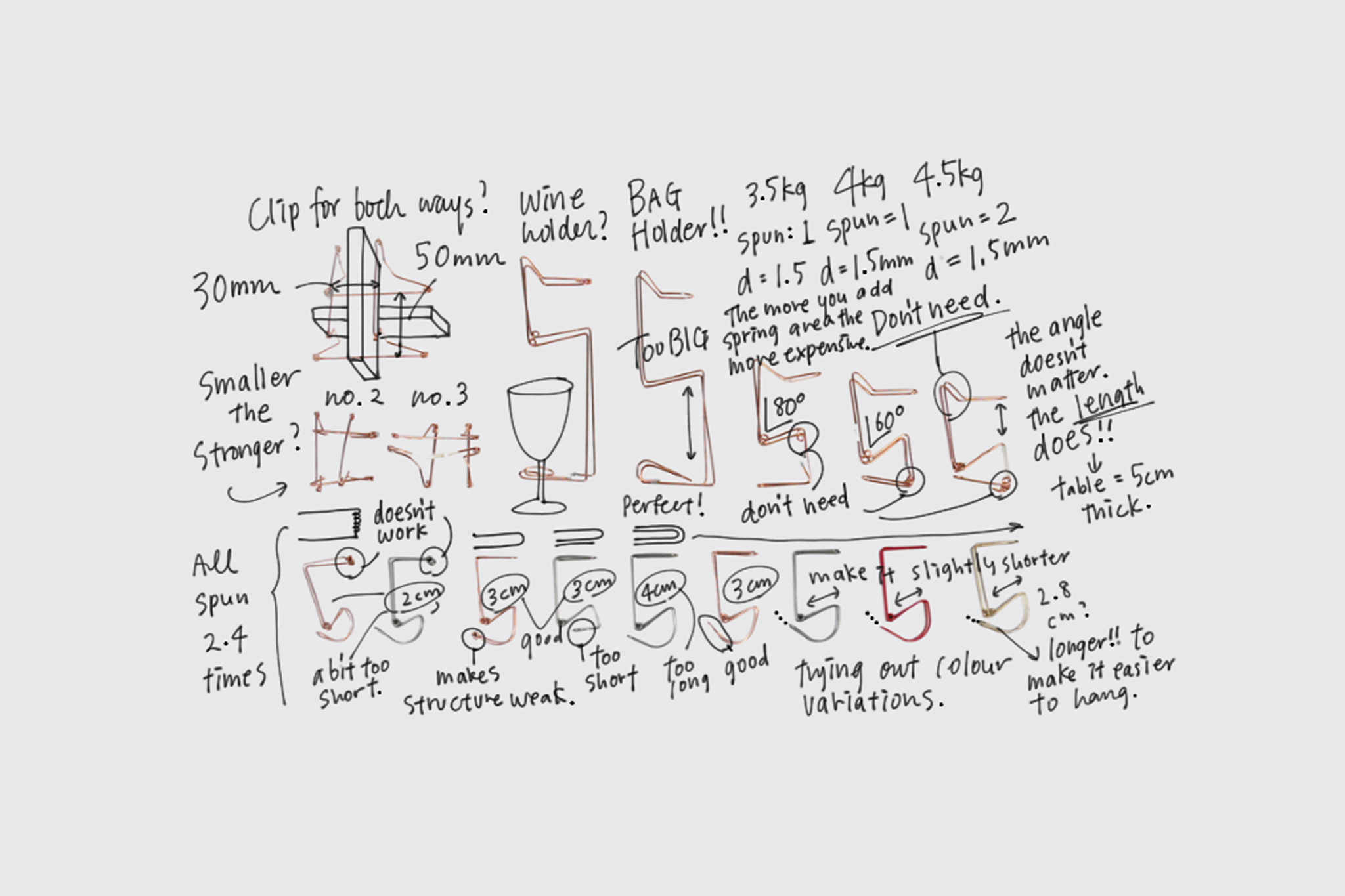

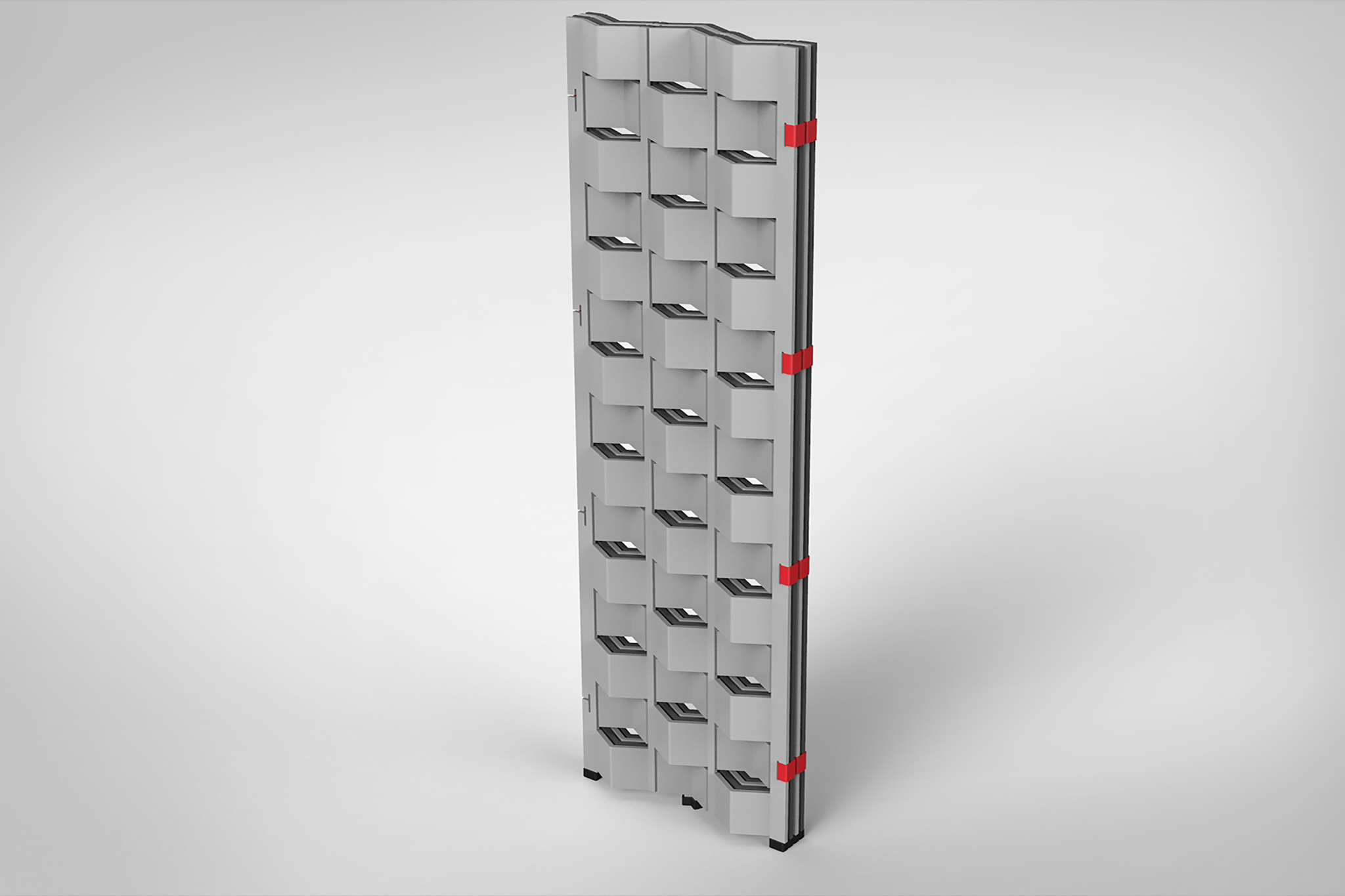

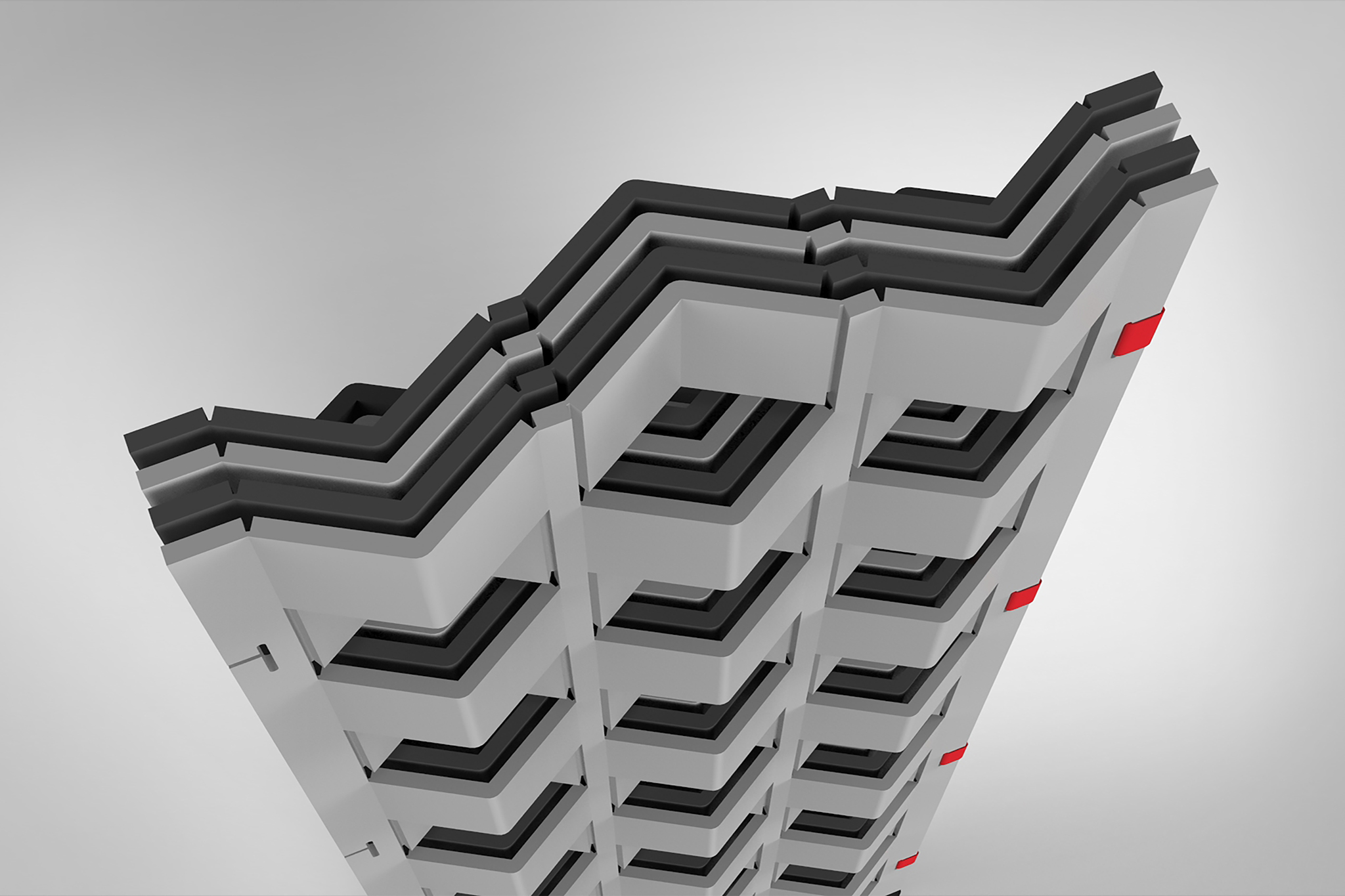

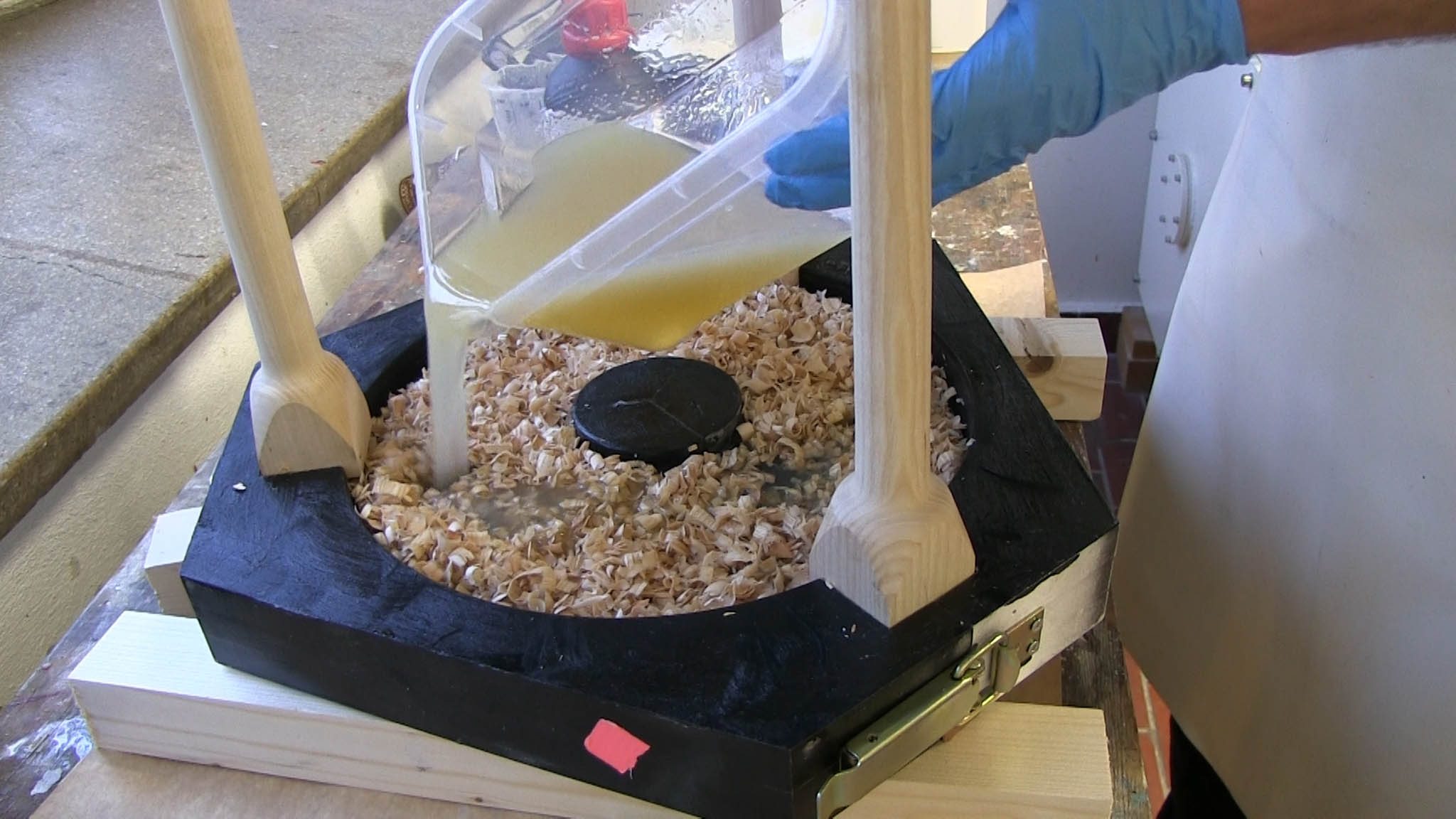

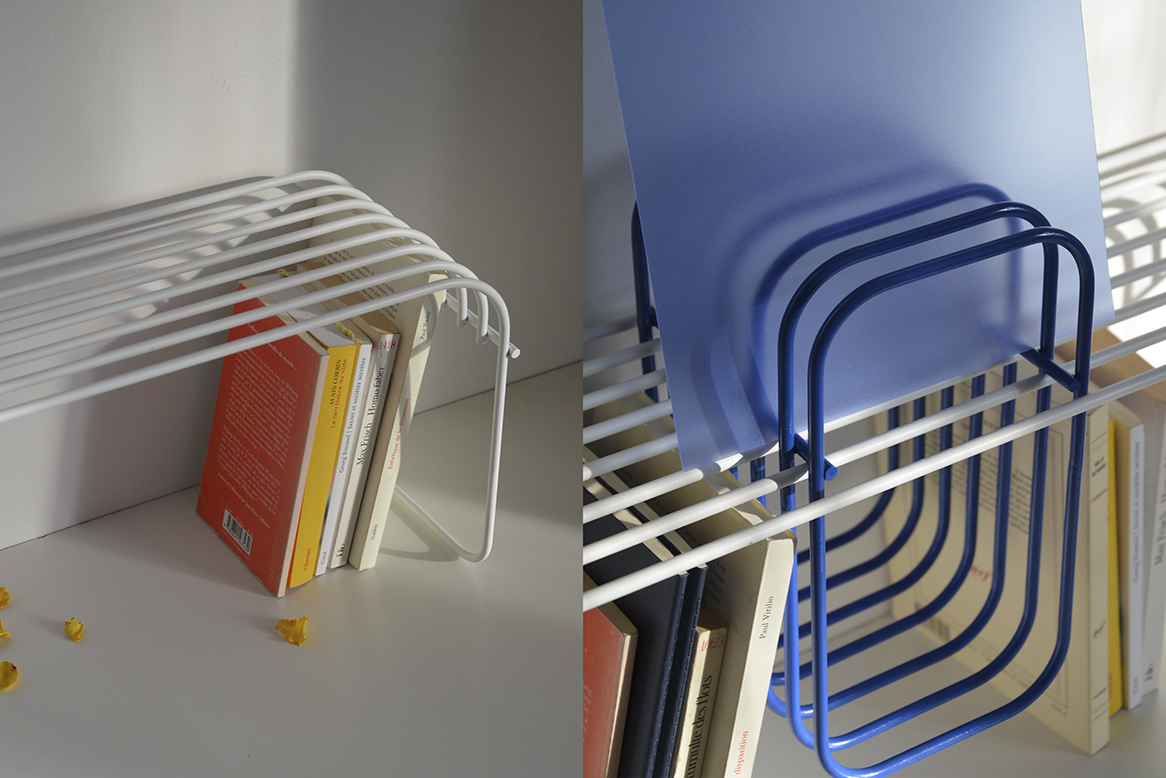

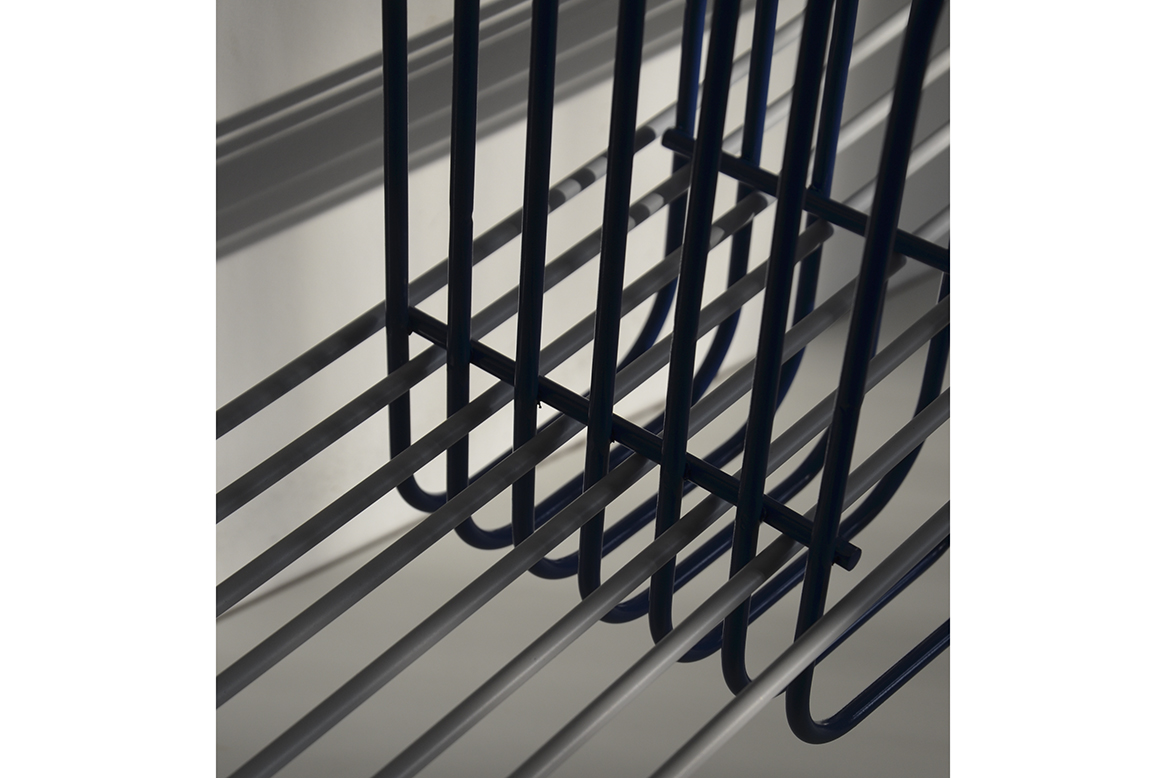

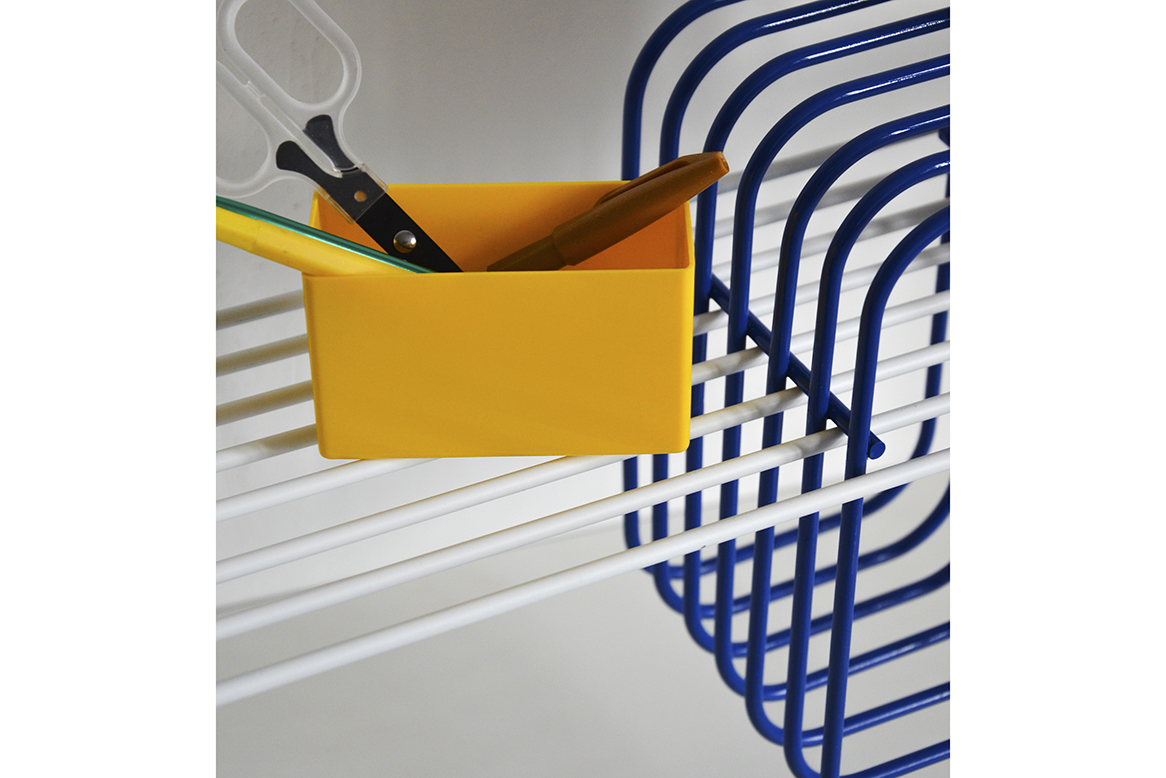

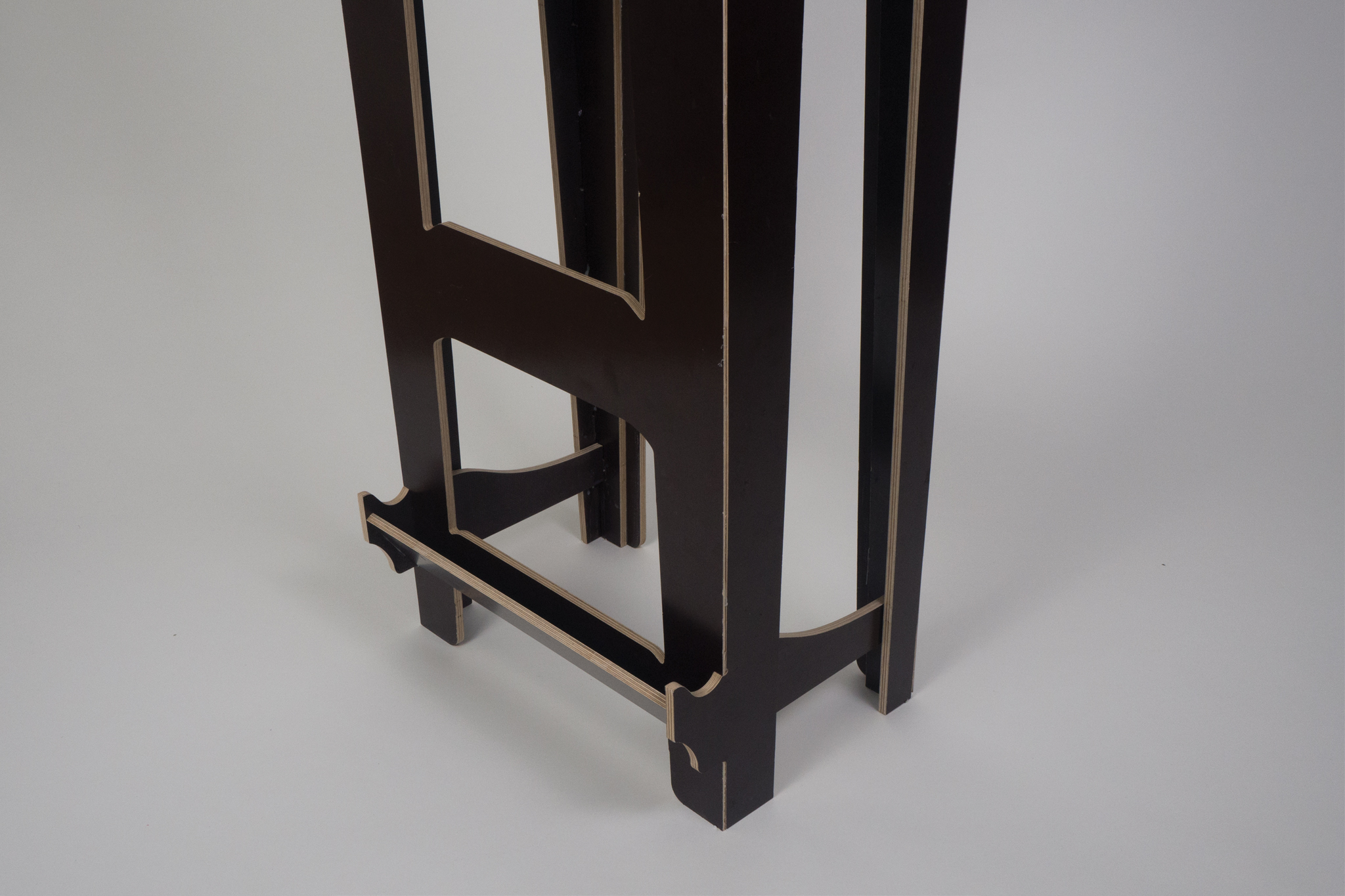

In POWER HOUSE students explored powerful alternatives for future living in a networked society where the internet of things is a reality, where growing digitisation in and around our houses request more and more products with plugs and power while – at the same time – we really have to slow down on our use of energy in the future. New products, projects, systems and strategies were developed that offer sensible and sustainable solutions for our houses, high-tech or low-tech.

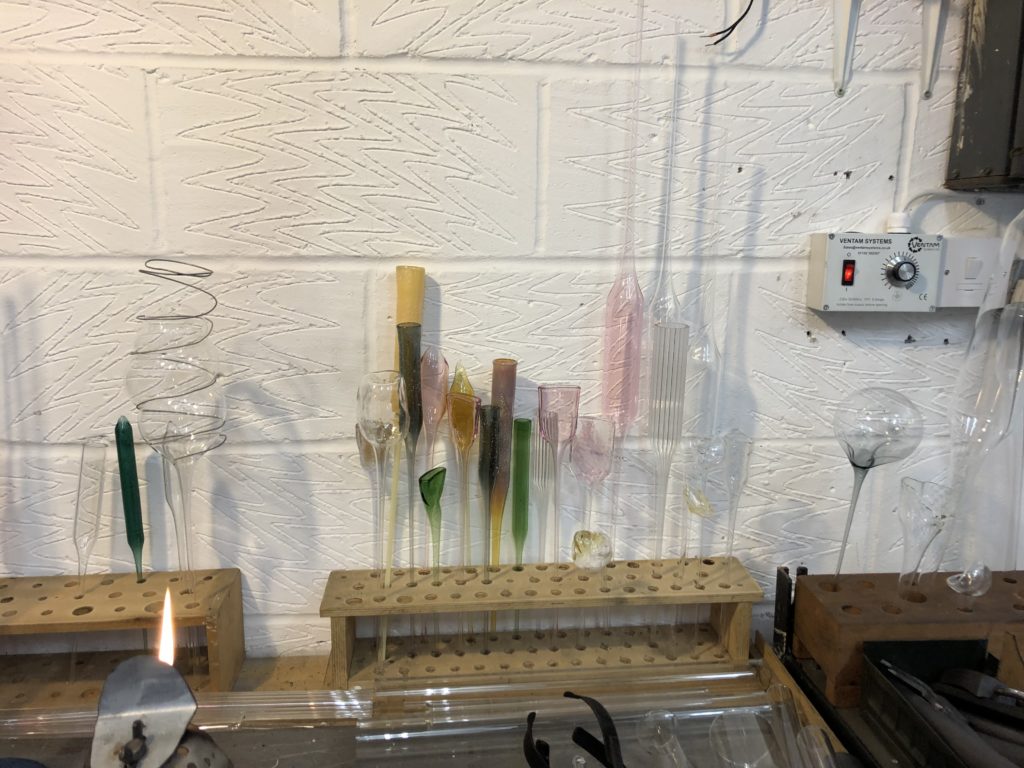

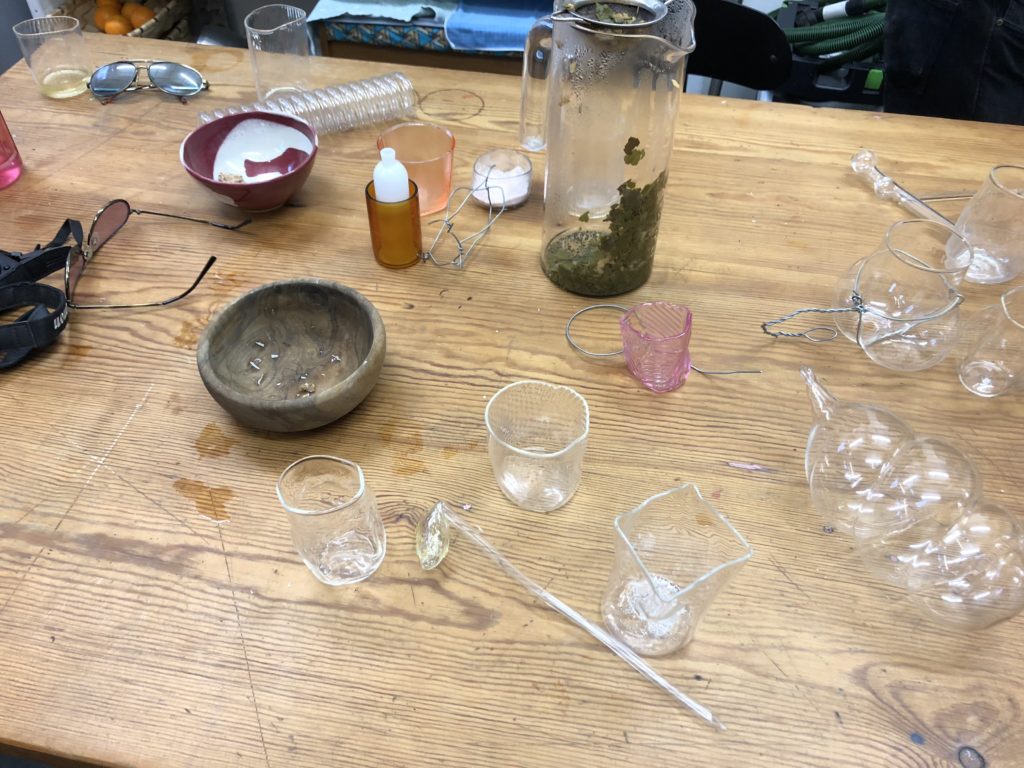

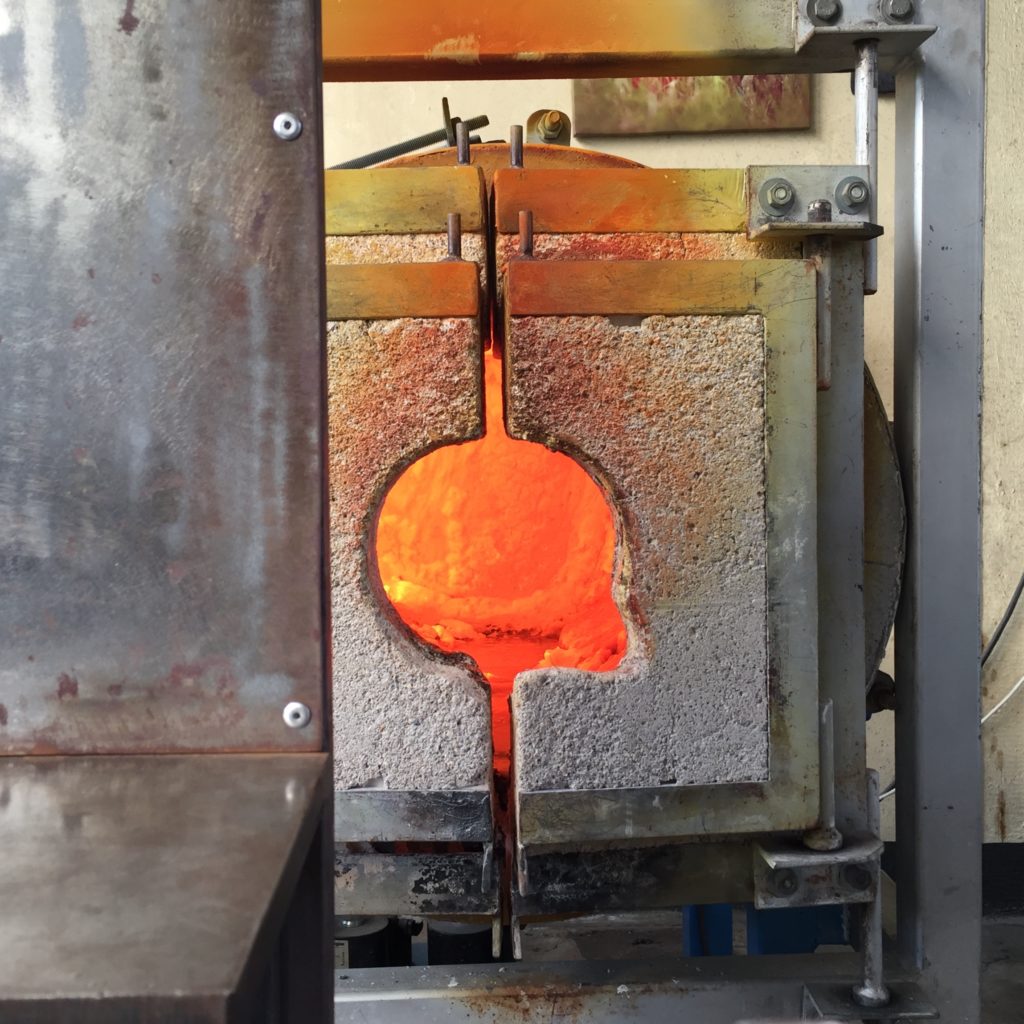

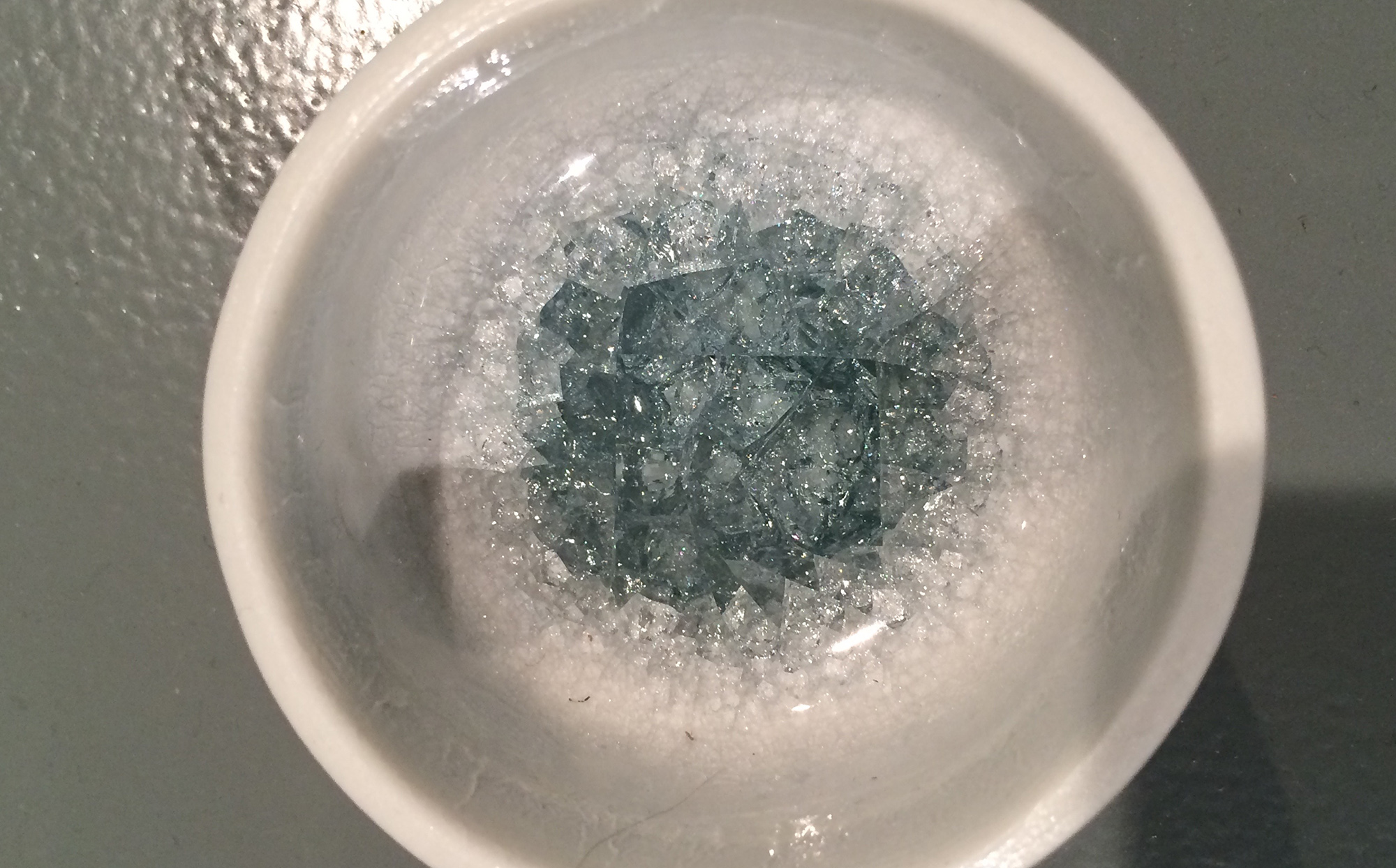

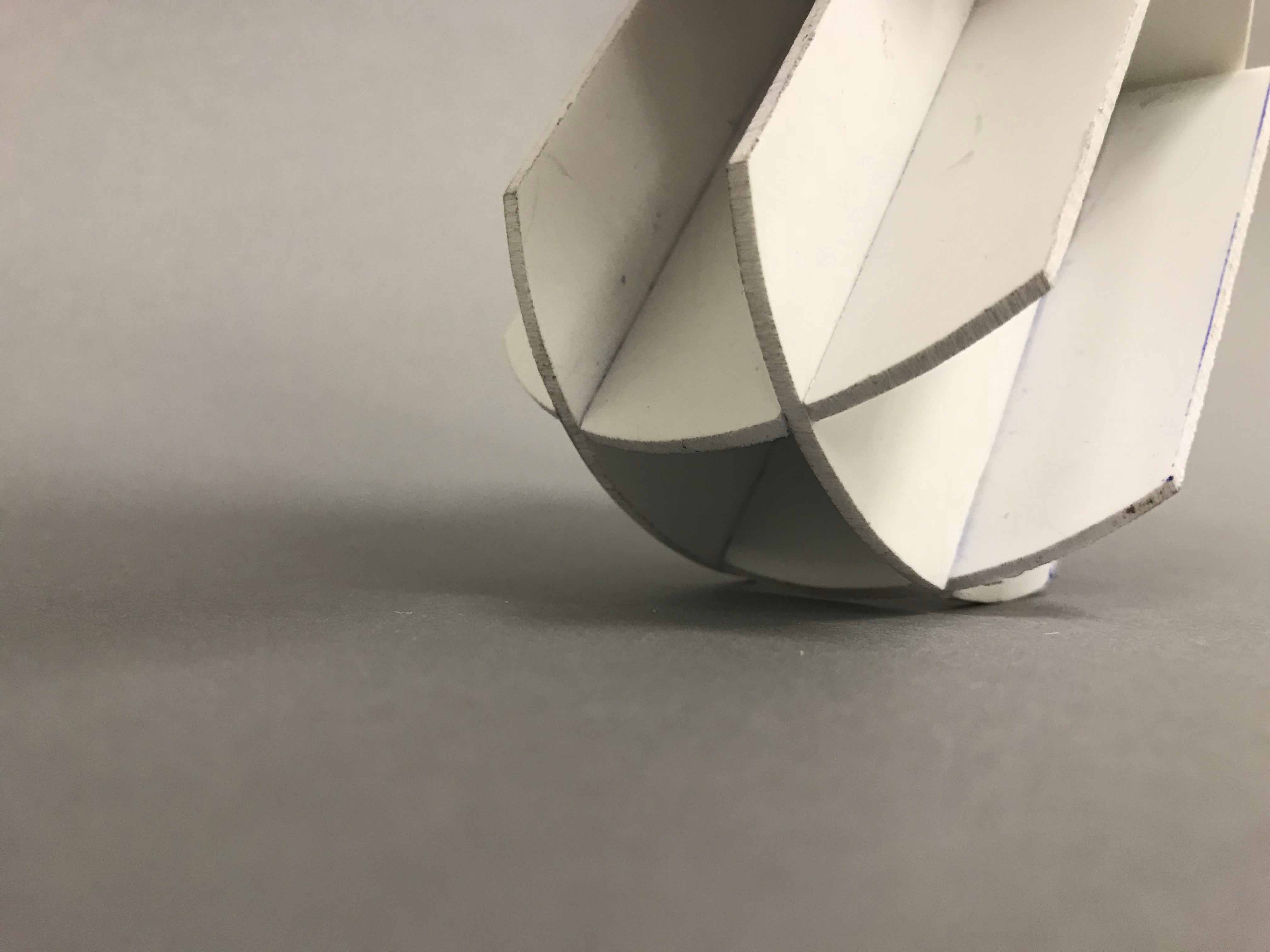

In CELEBRATING GLASS students discovered glass in all its aspects through study trips and workshops in Berlin, London and Meisenthal in France. By exploring glass blowing and lampworking to disforming glass in other ways they designed objects that celebratethe material: that evoke happiness, that jubilate, that commemorate special moments, honour peculiar uses, specific functions, or just revel the experiment. The glass projects that came about in a joint workshop with students of HBK-Saar in Meisenthal will be on show at Designblok Prag in Oktober 2018.

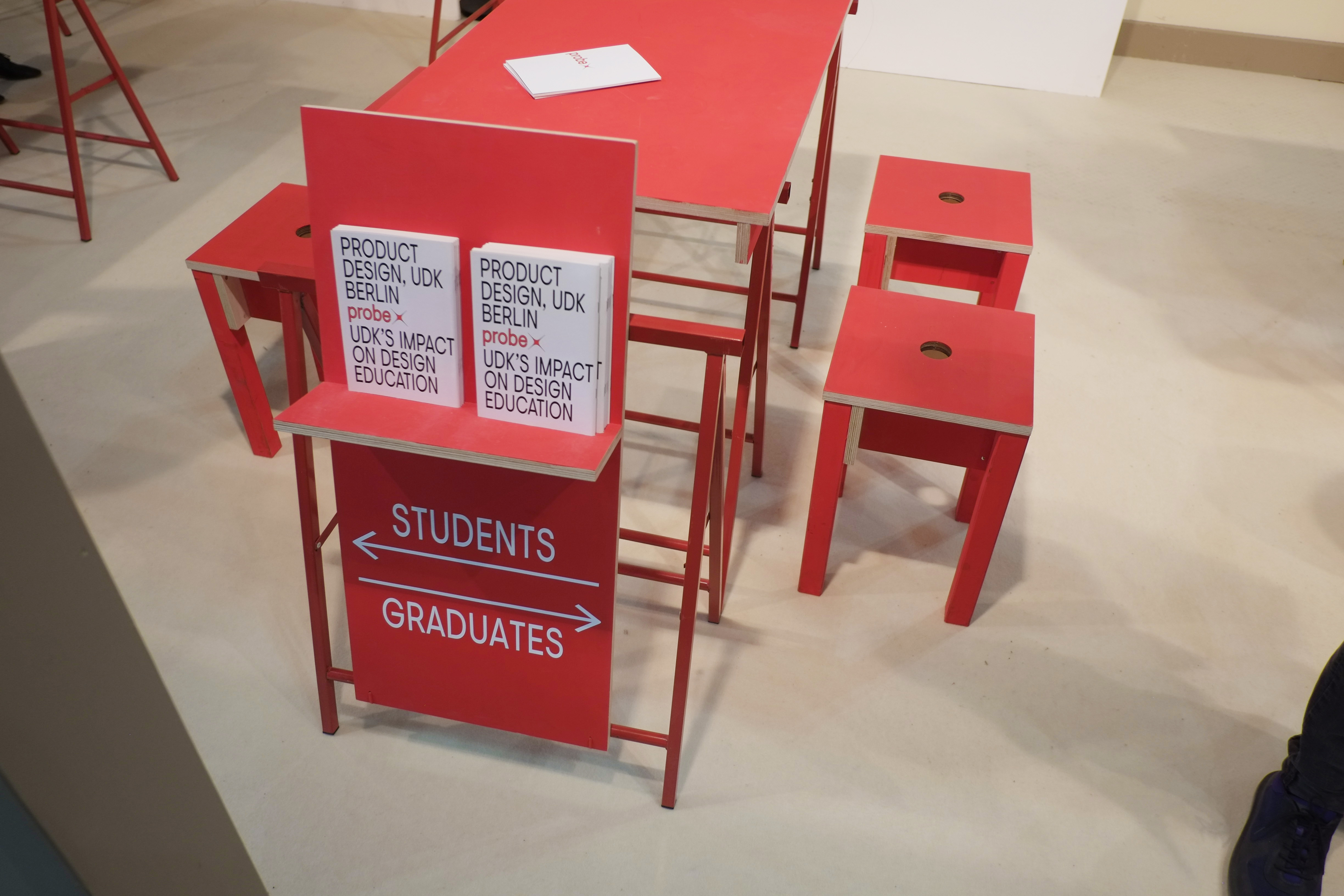

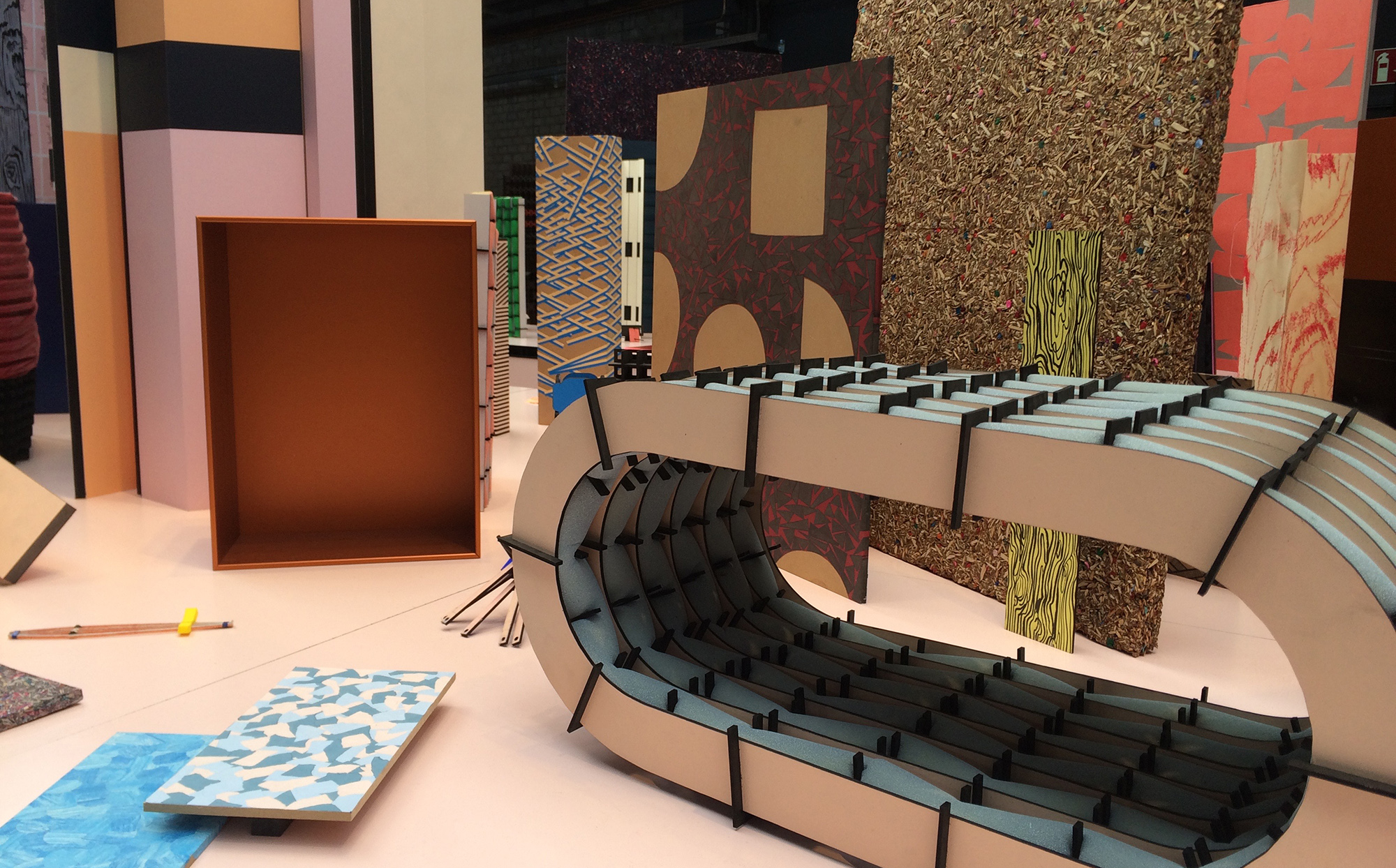

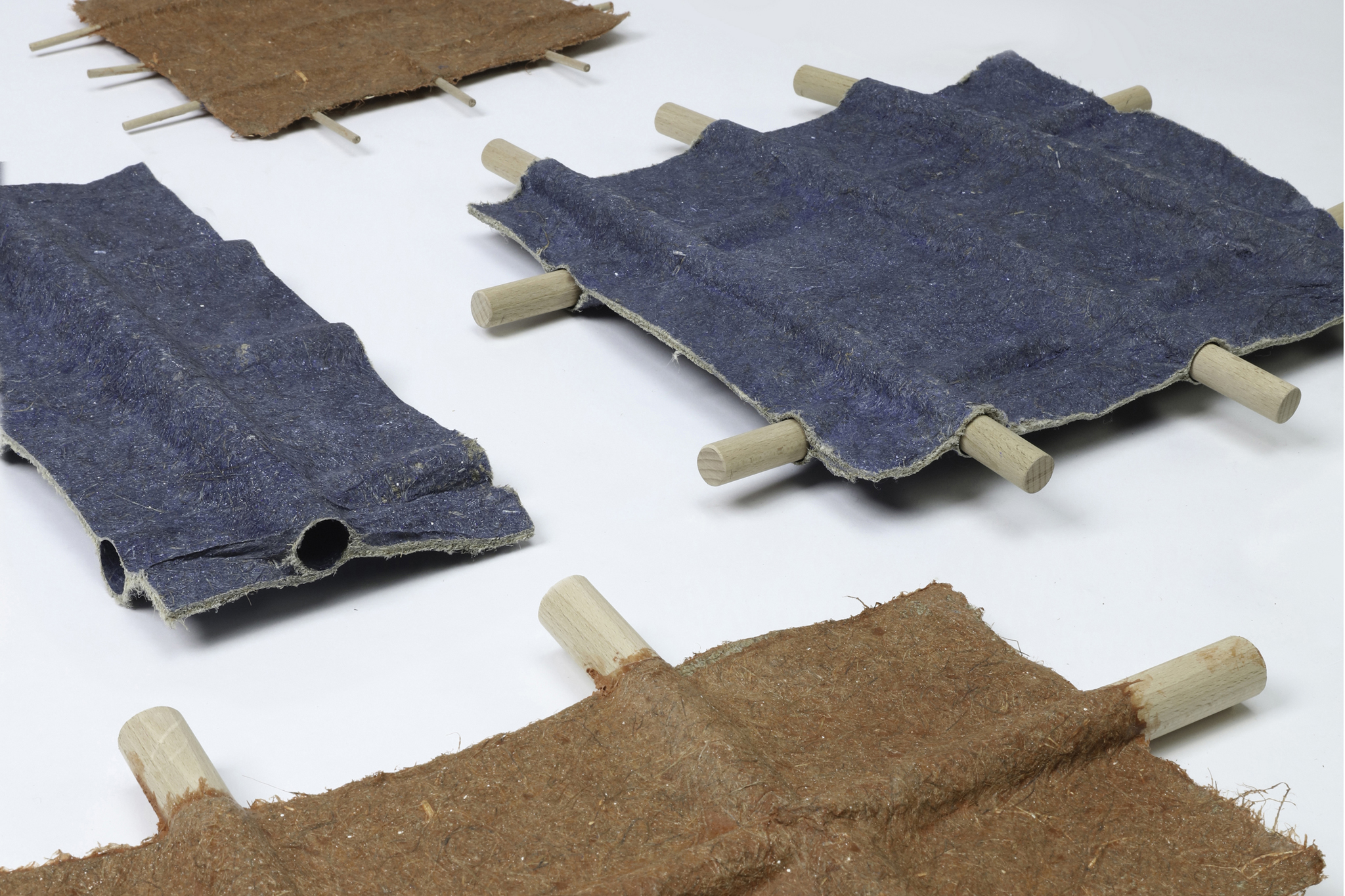

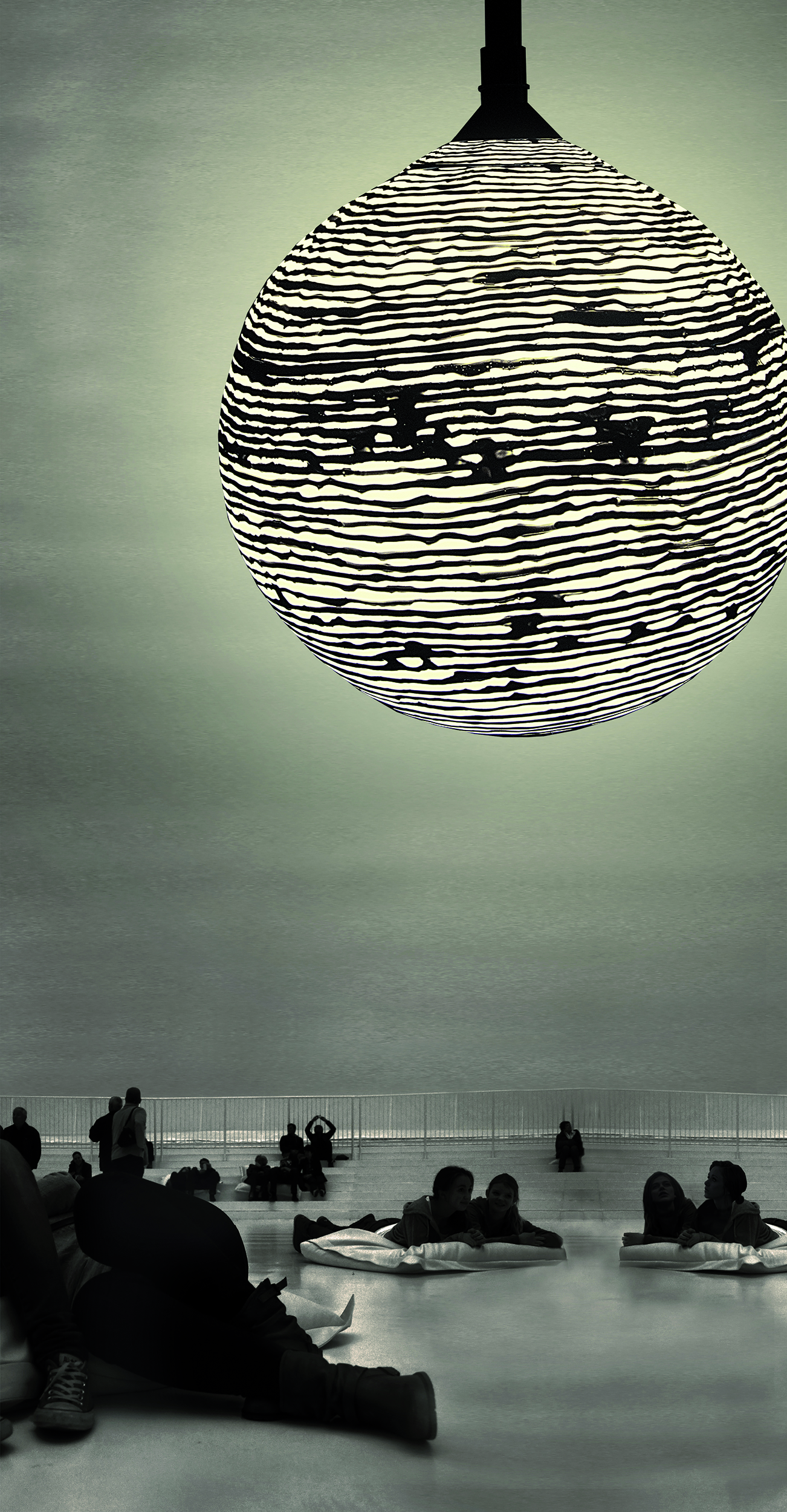

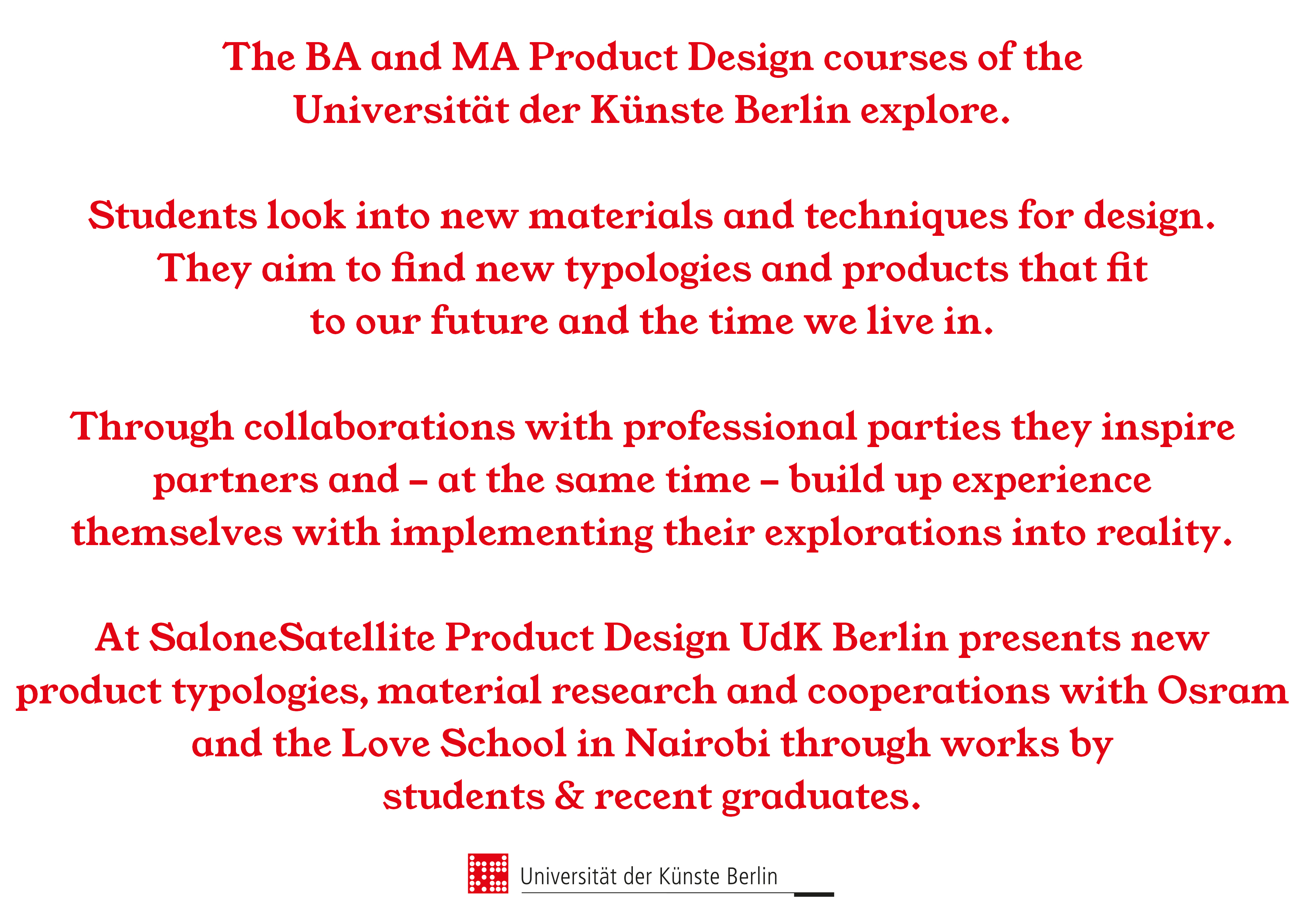

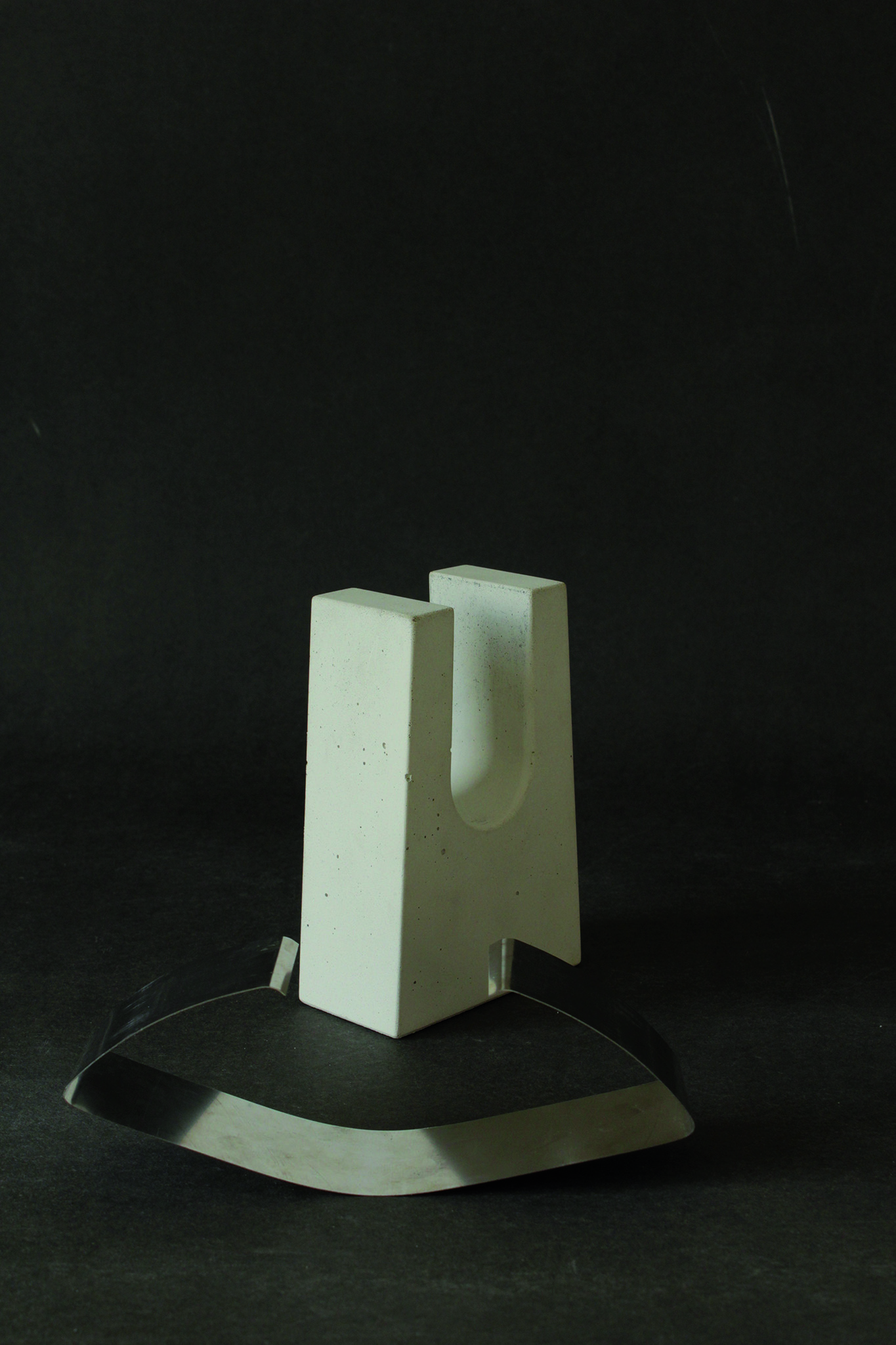

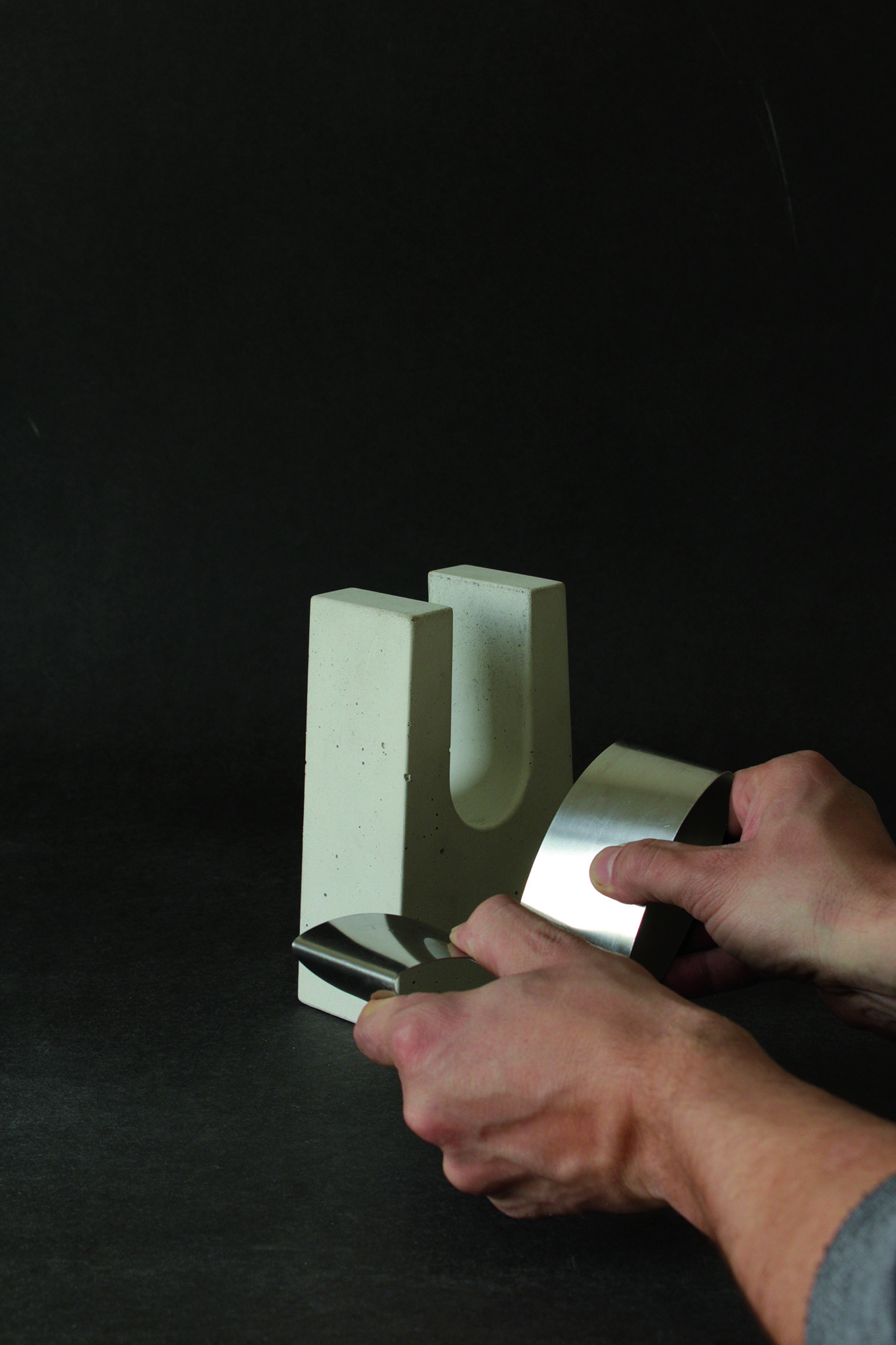

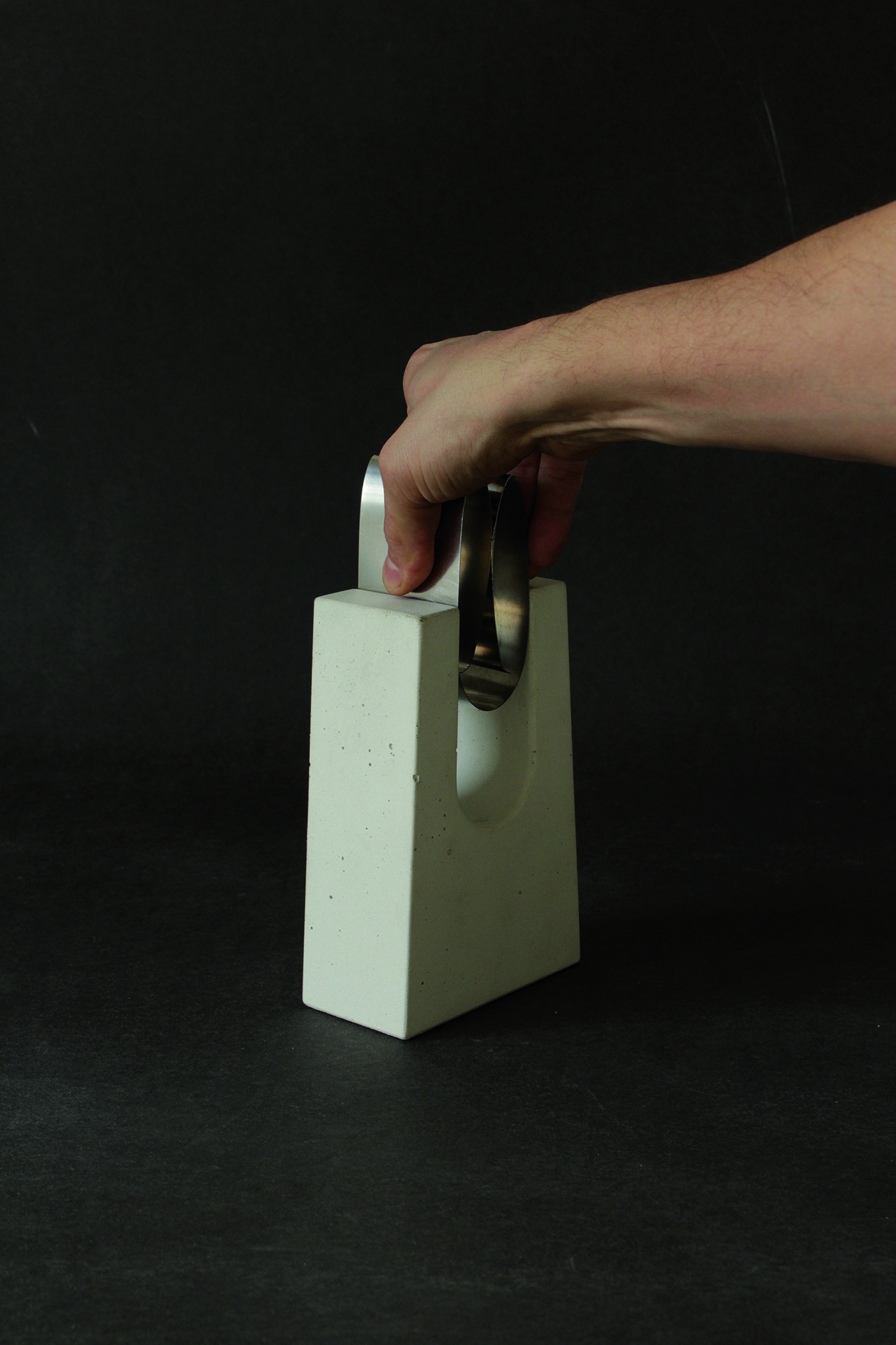

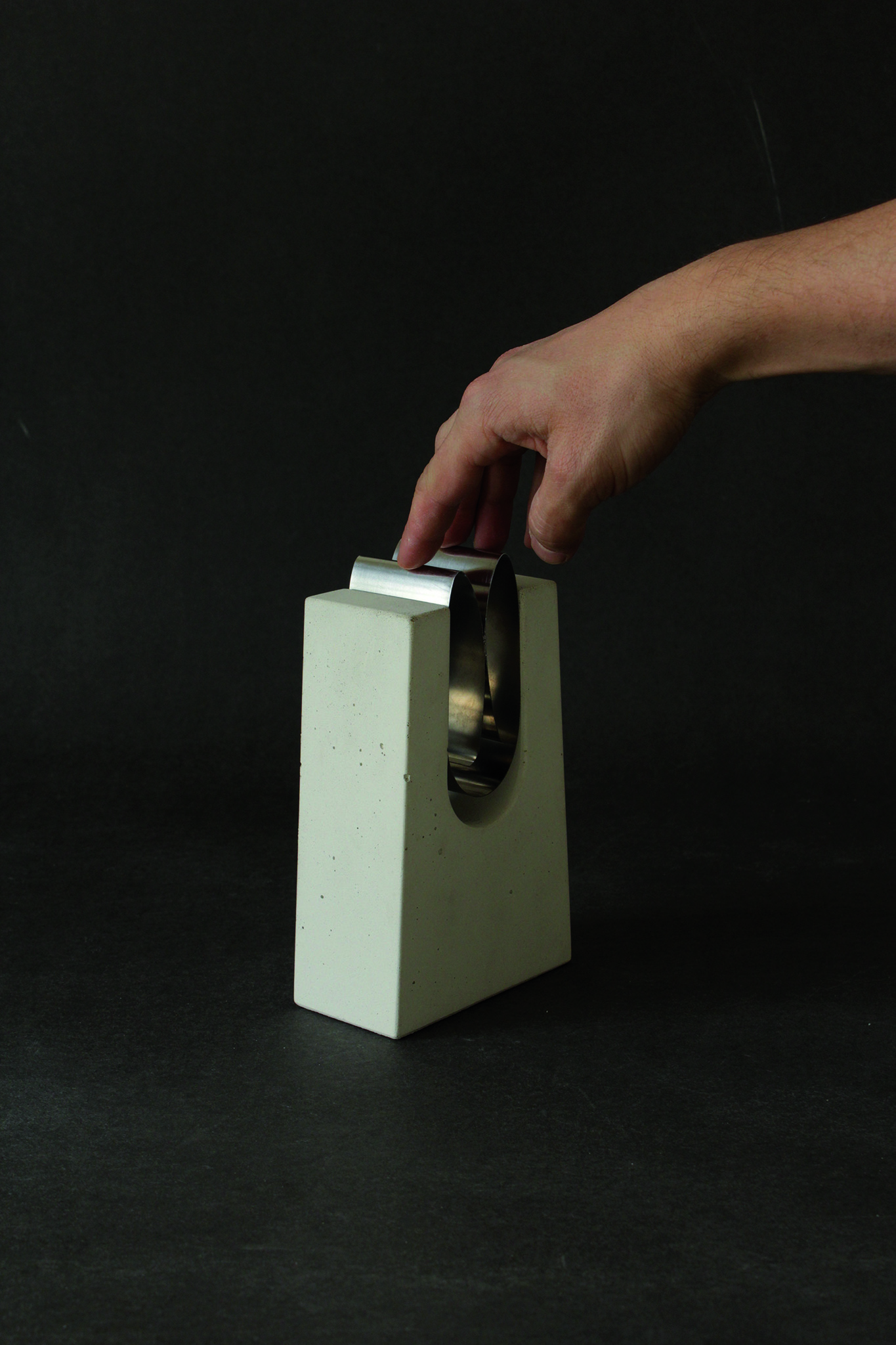

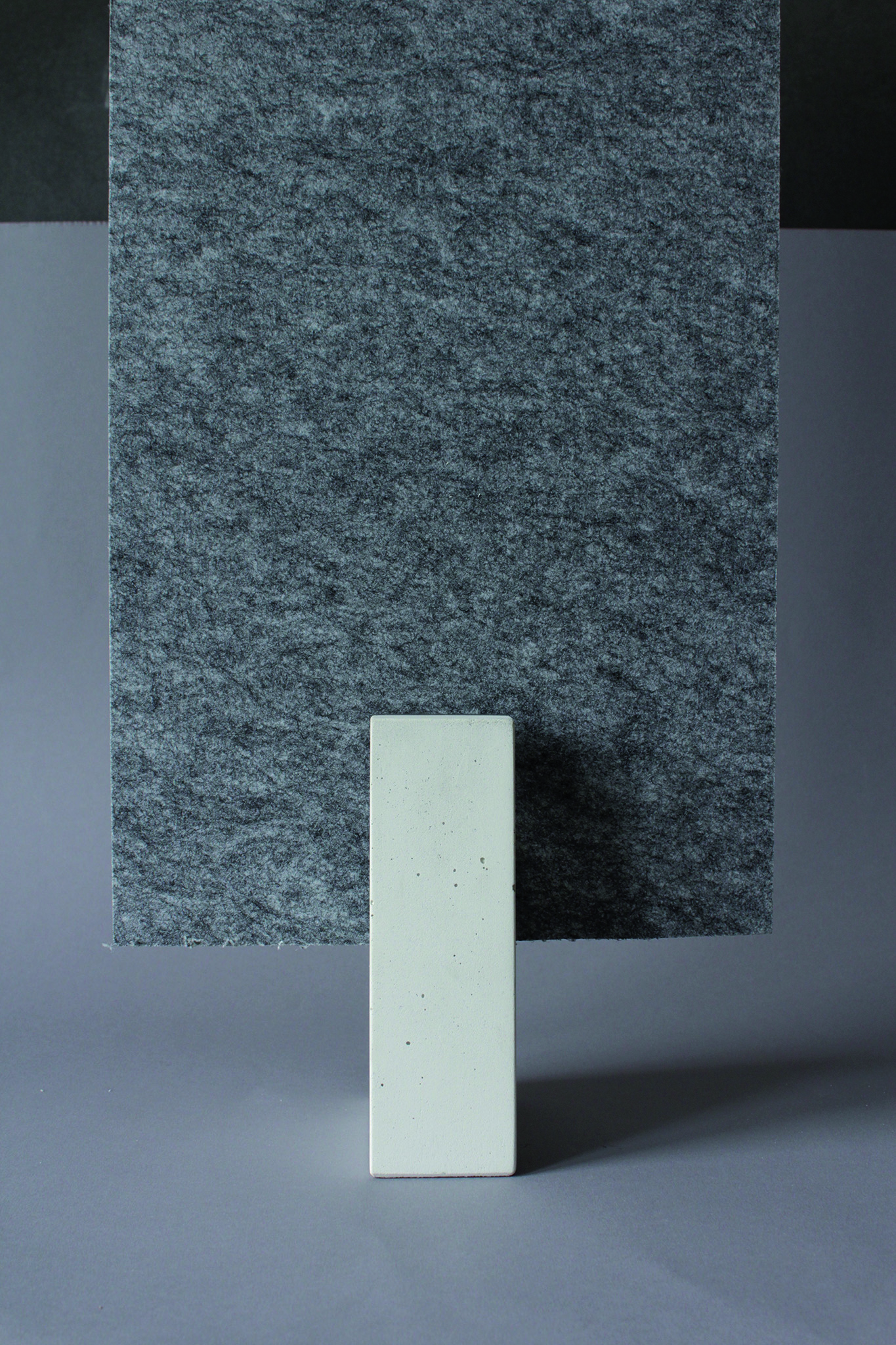

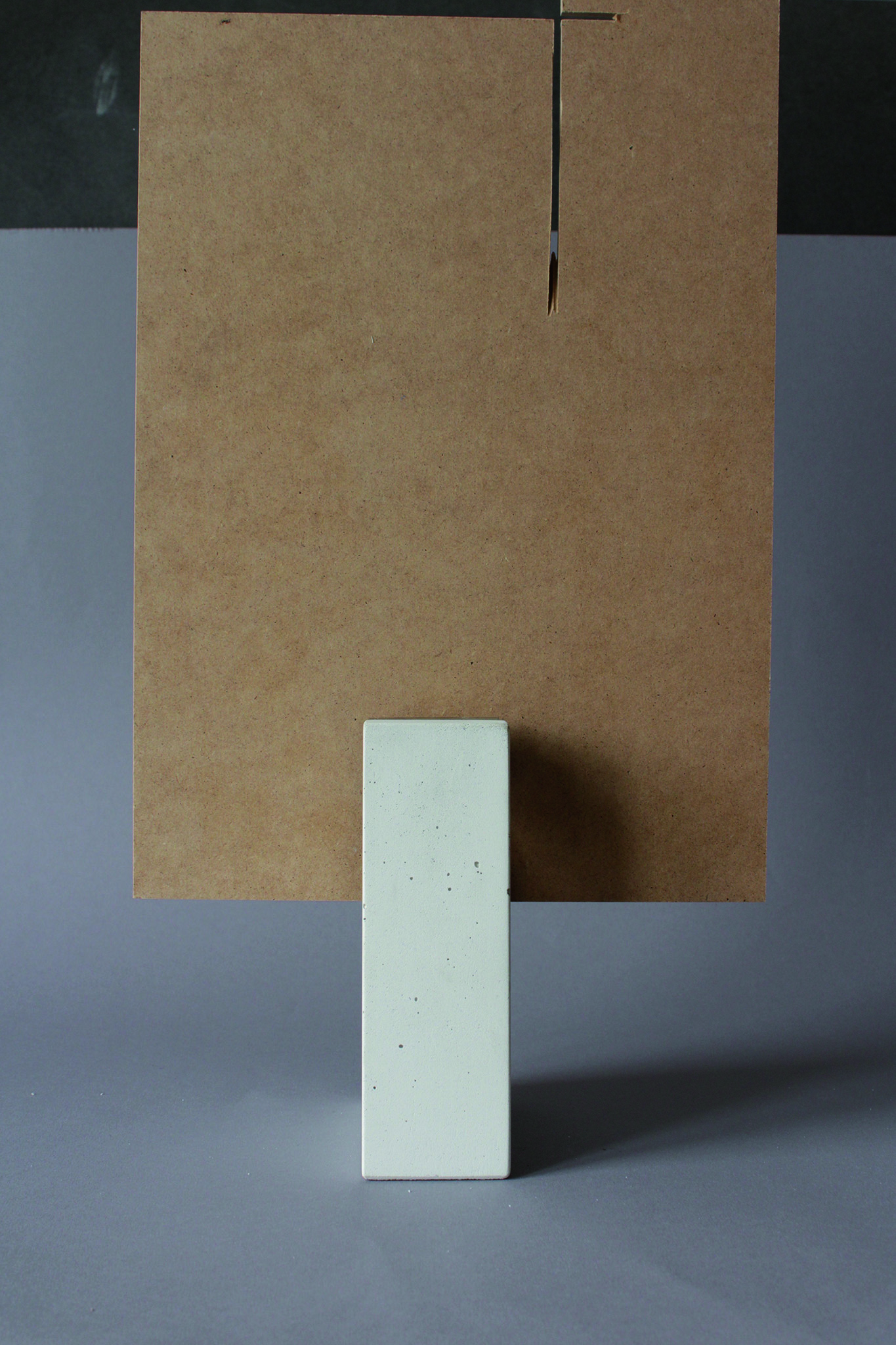

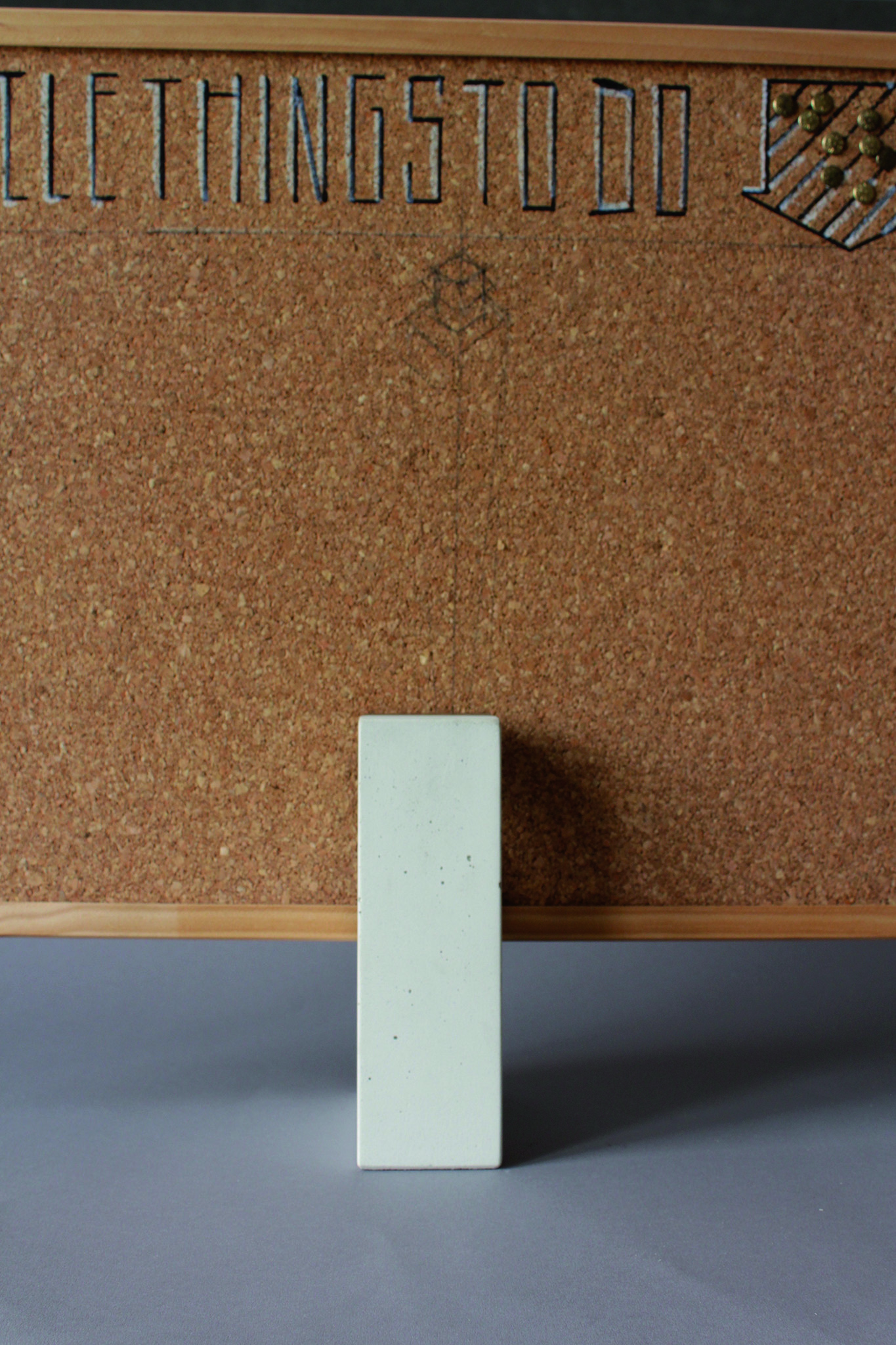

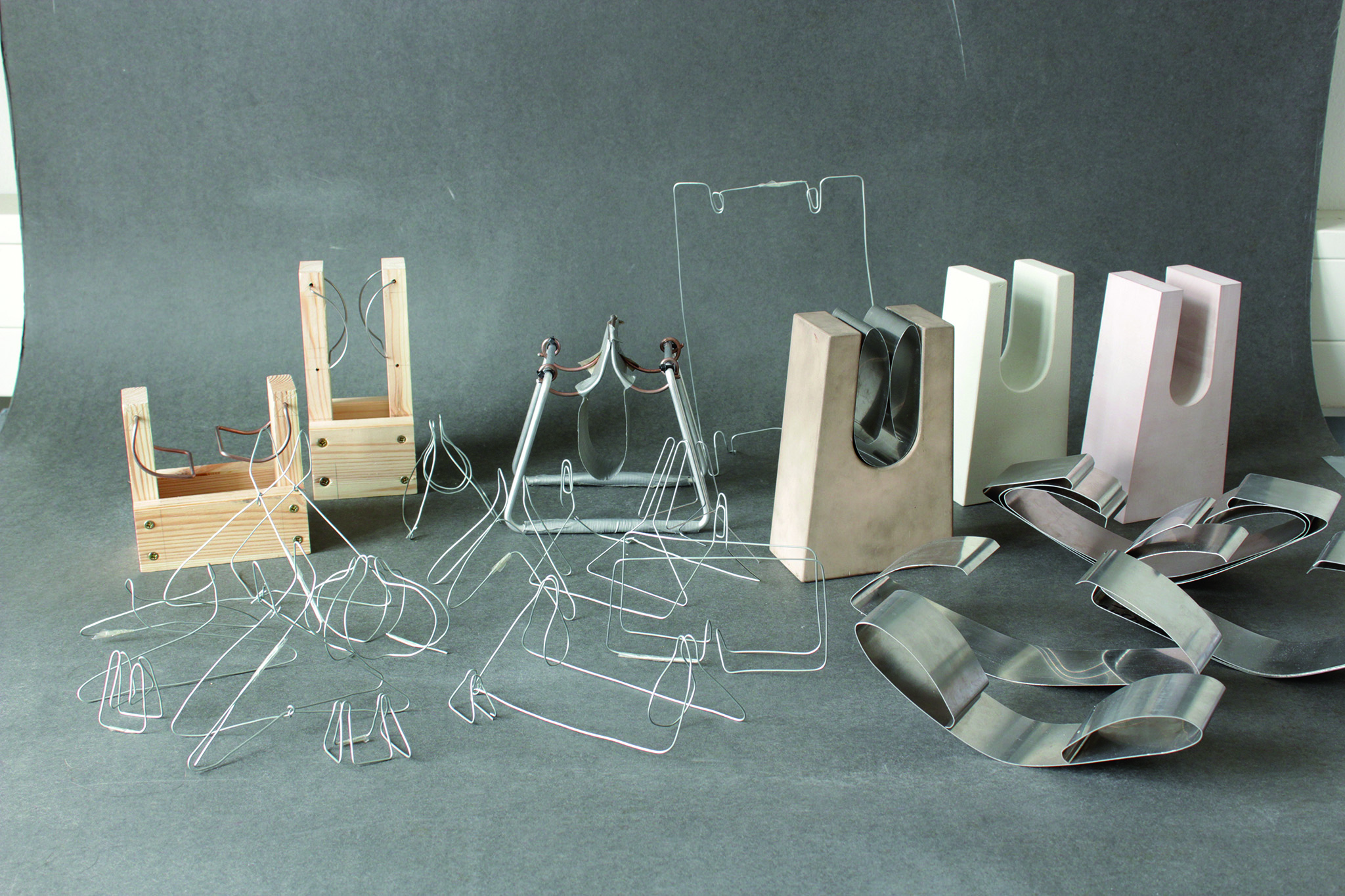

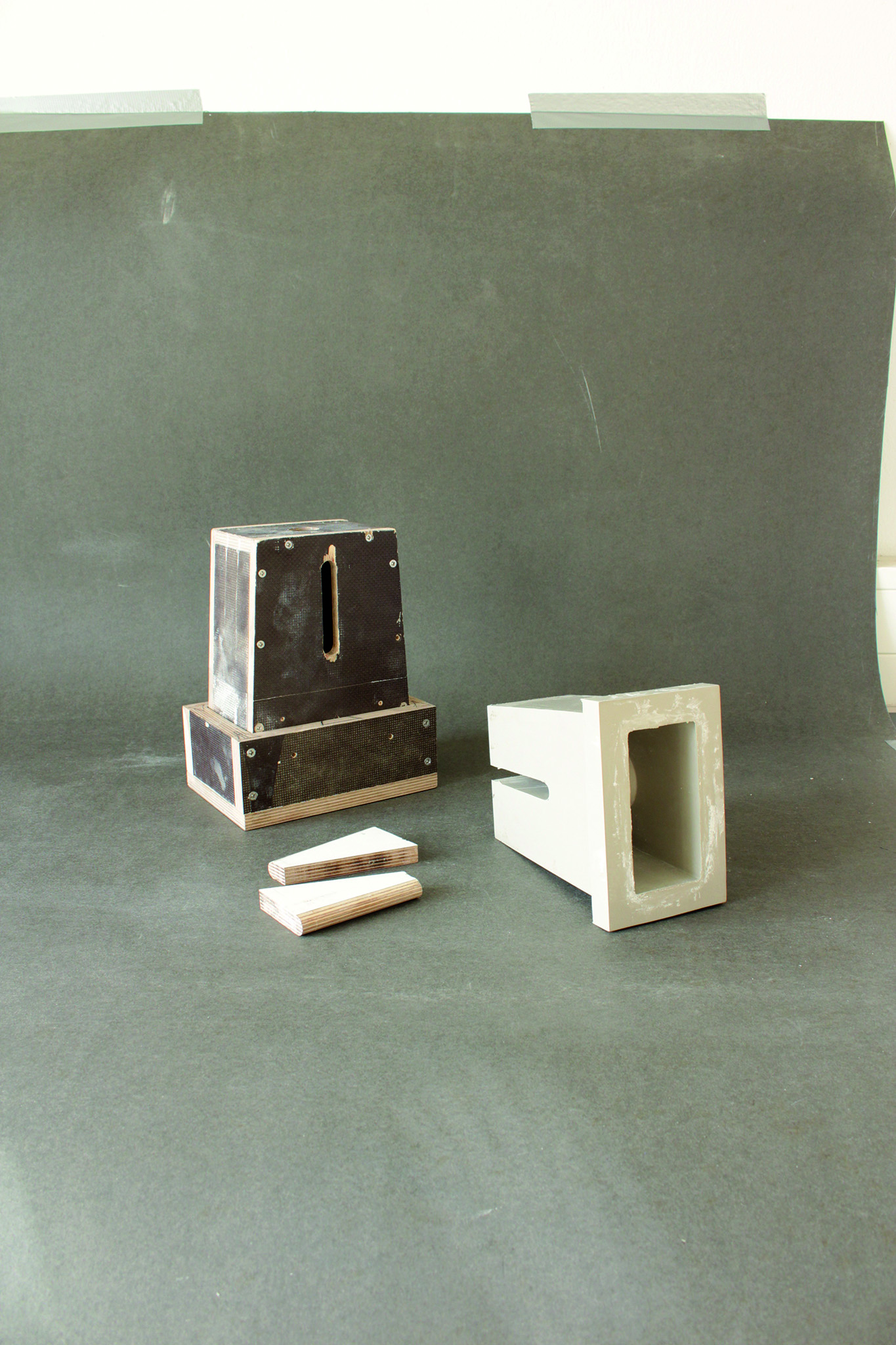

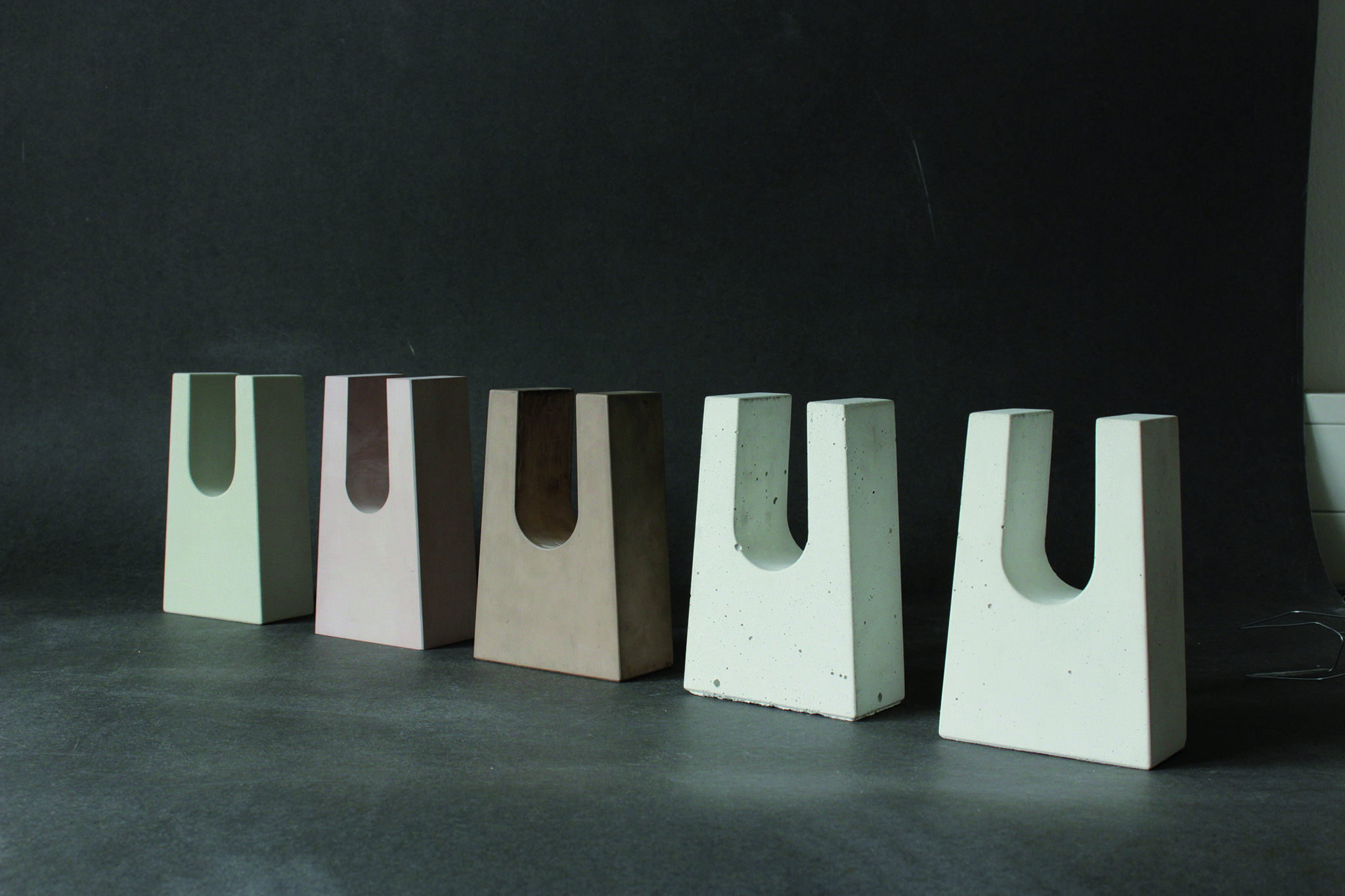

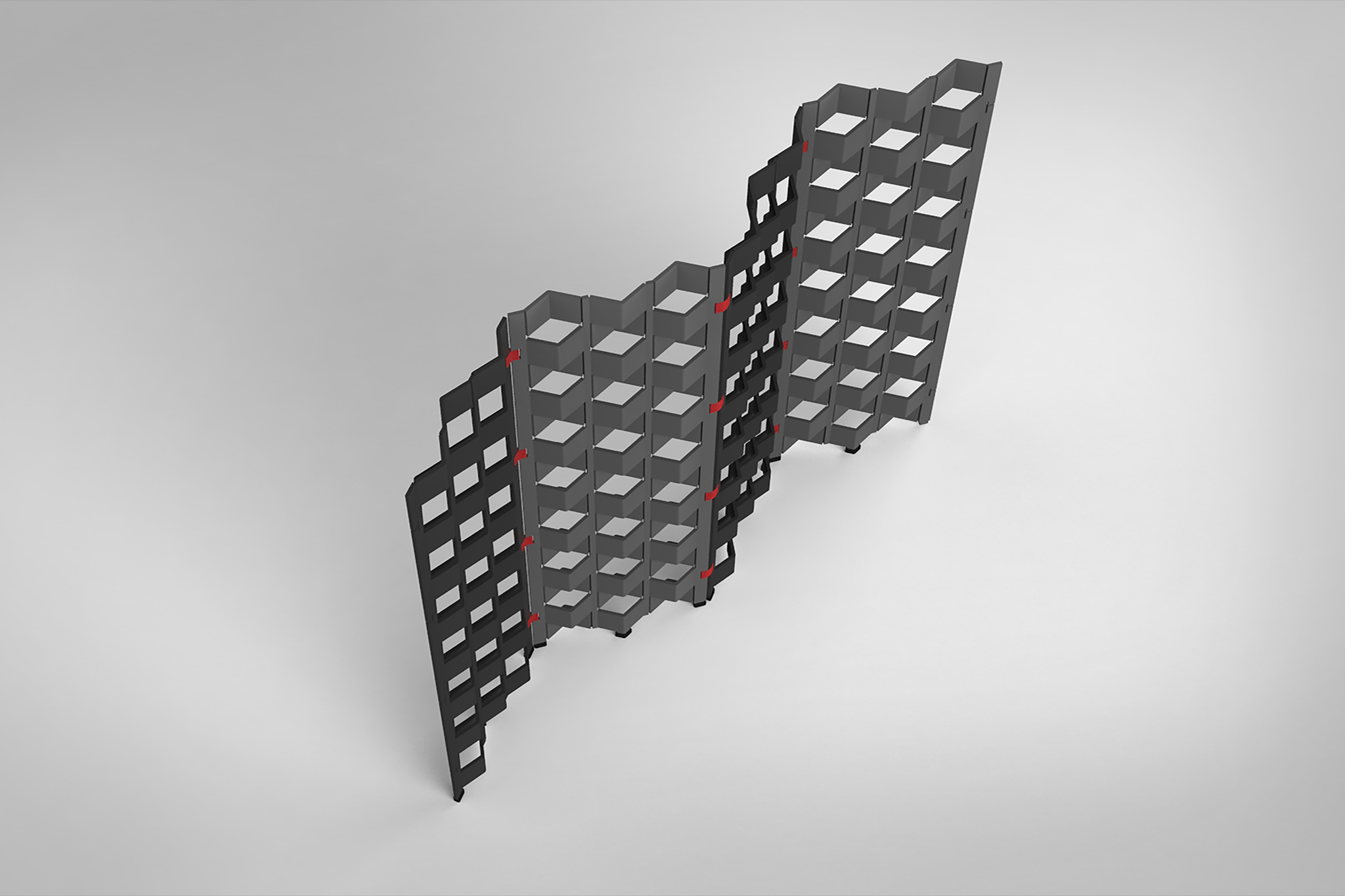

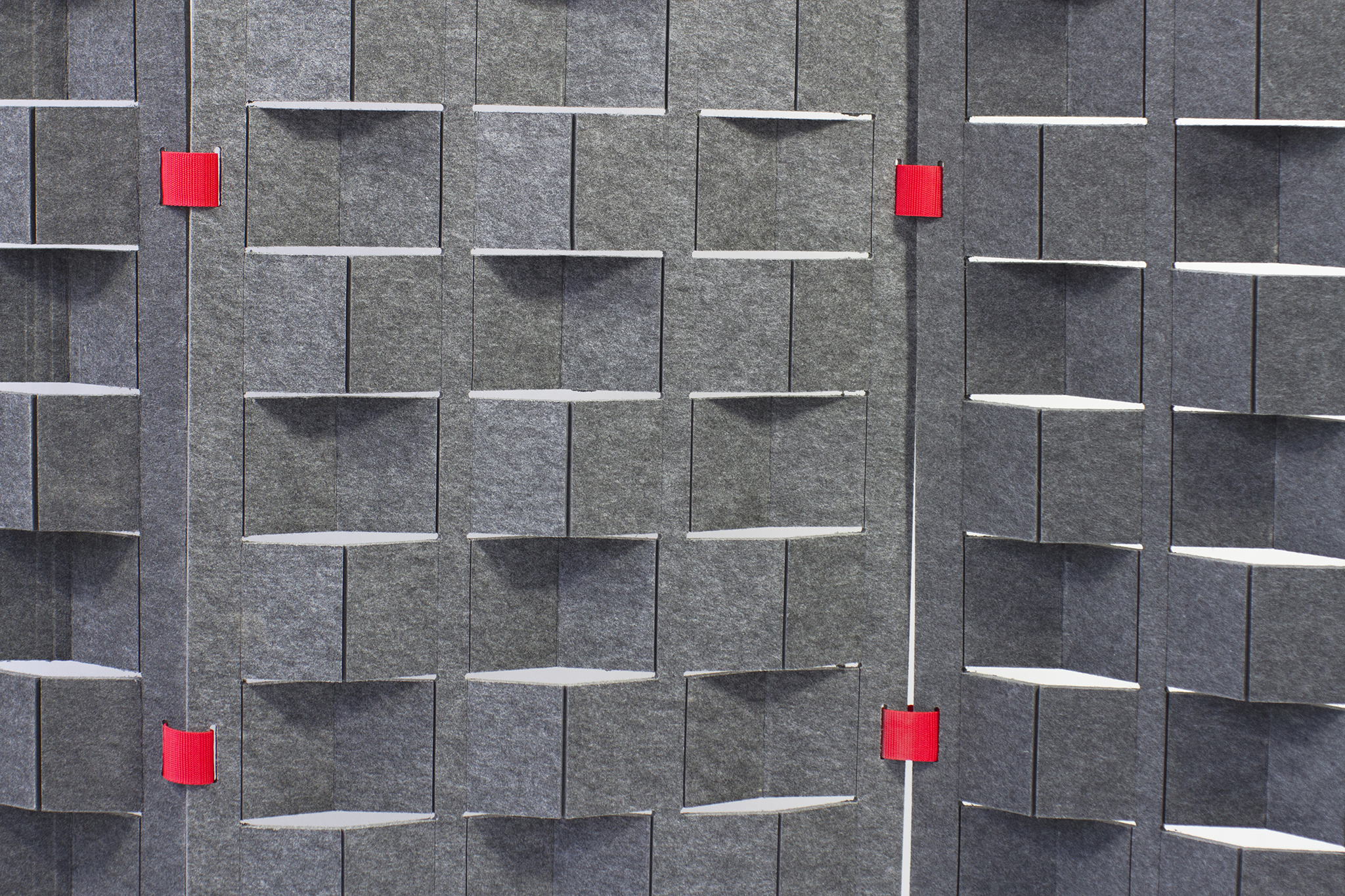

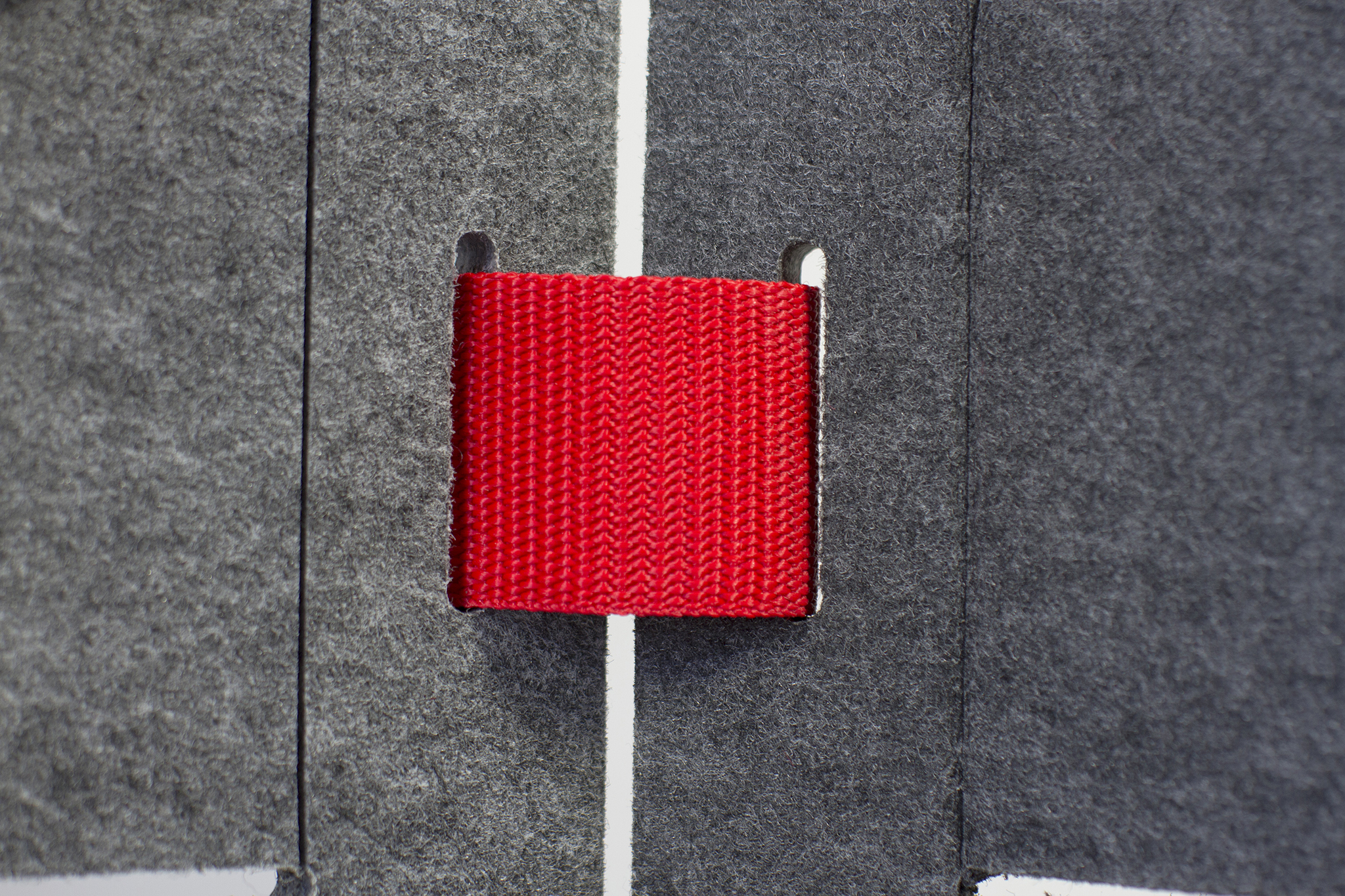

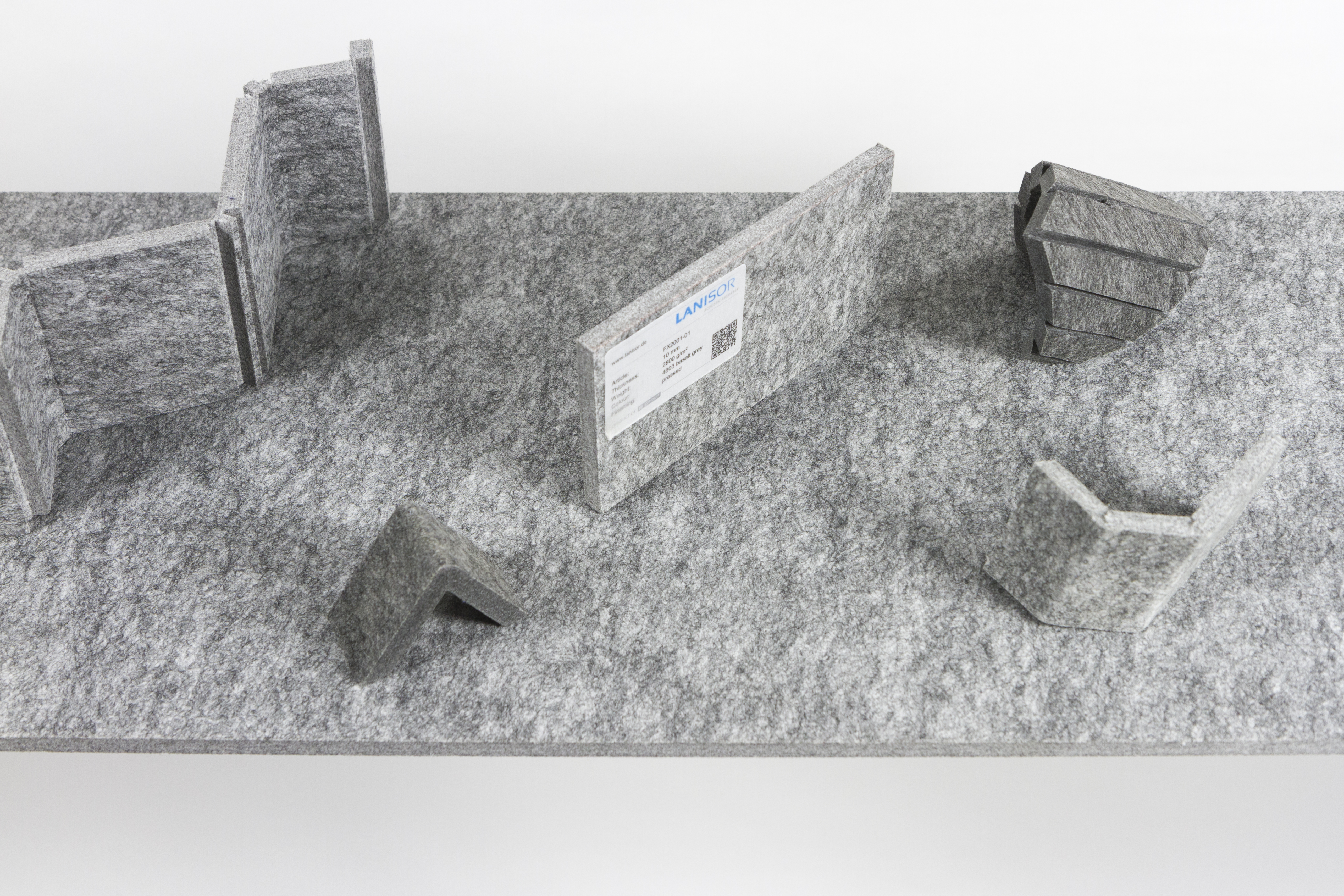

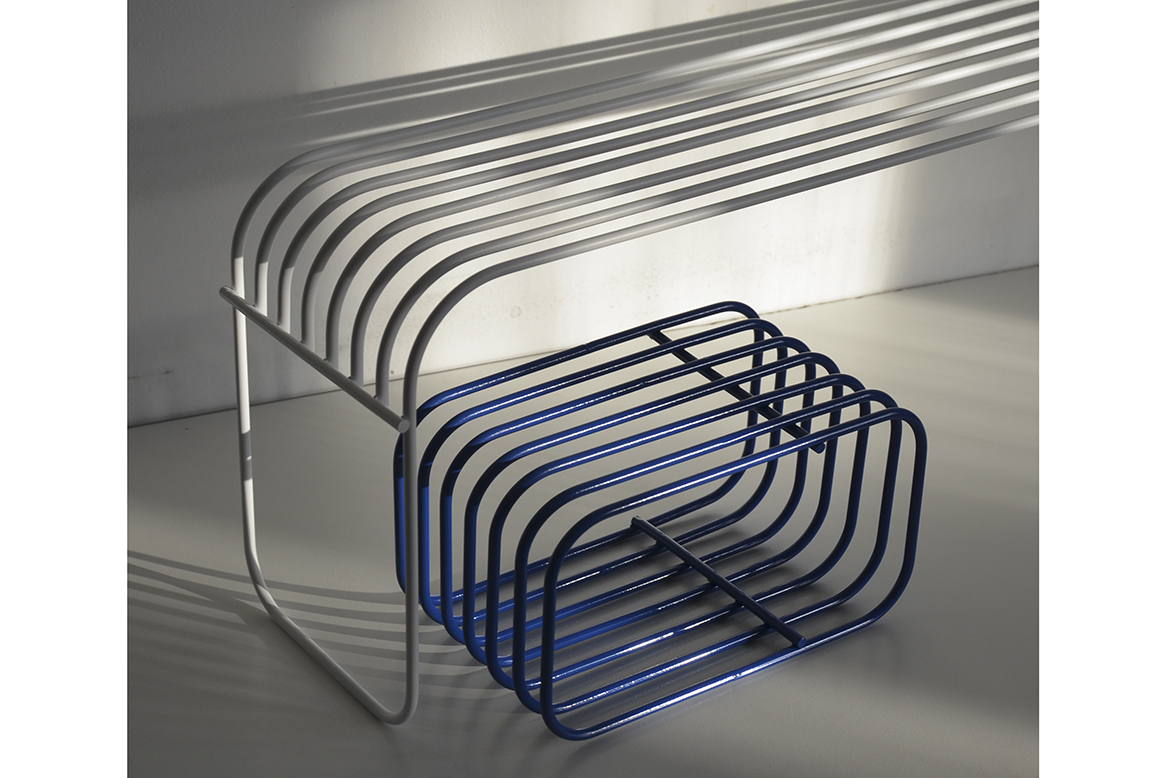

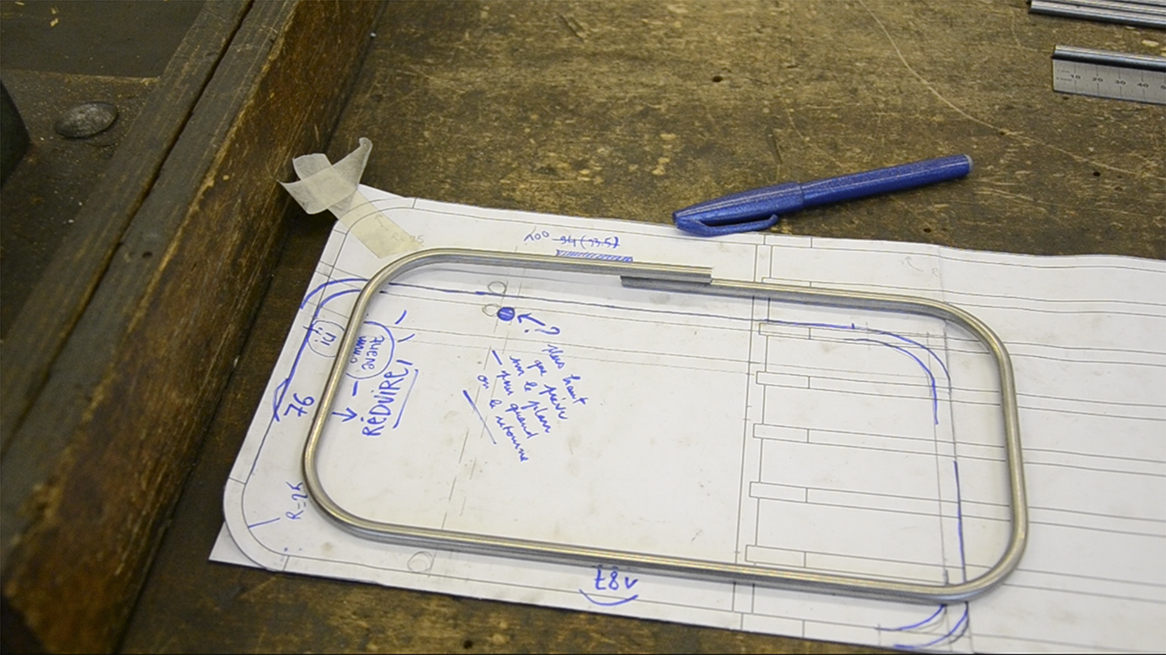

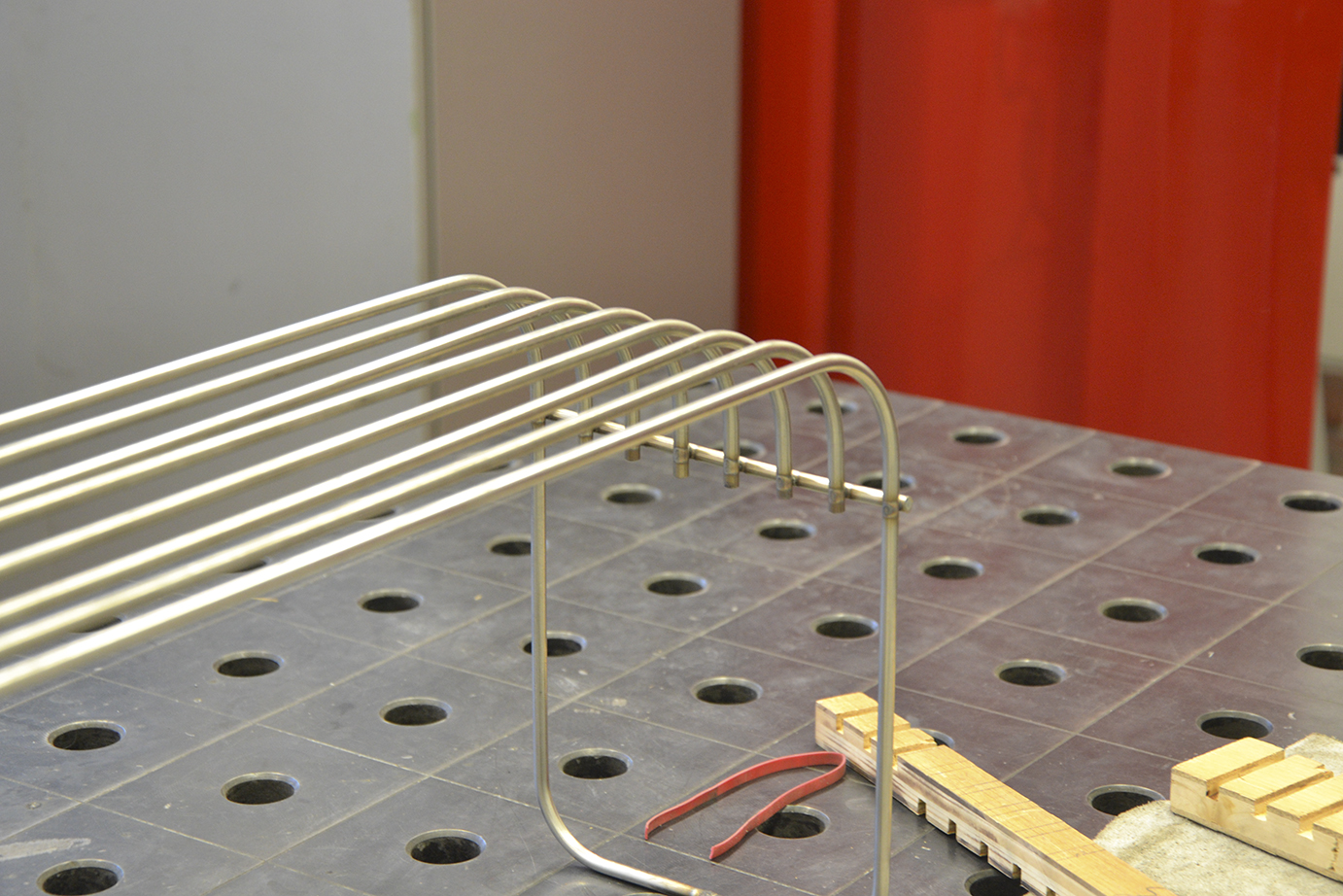

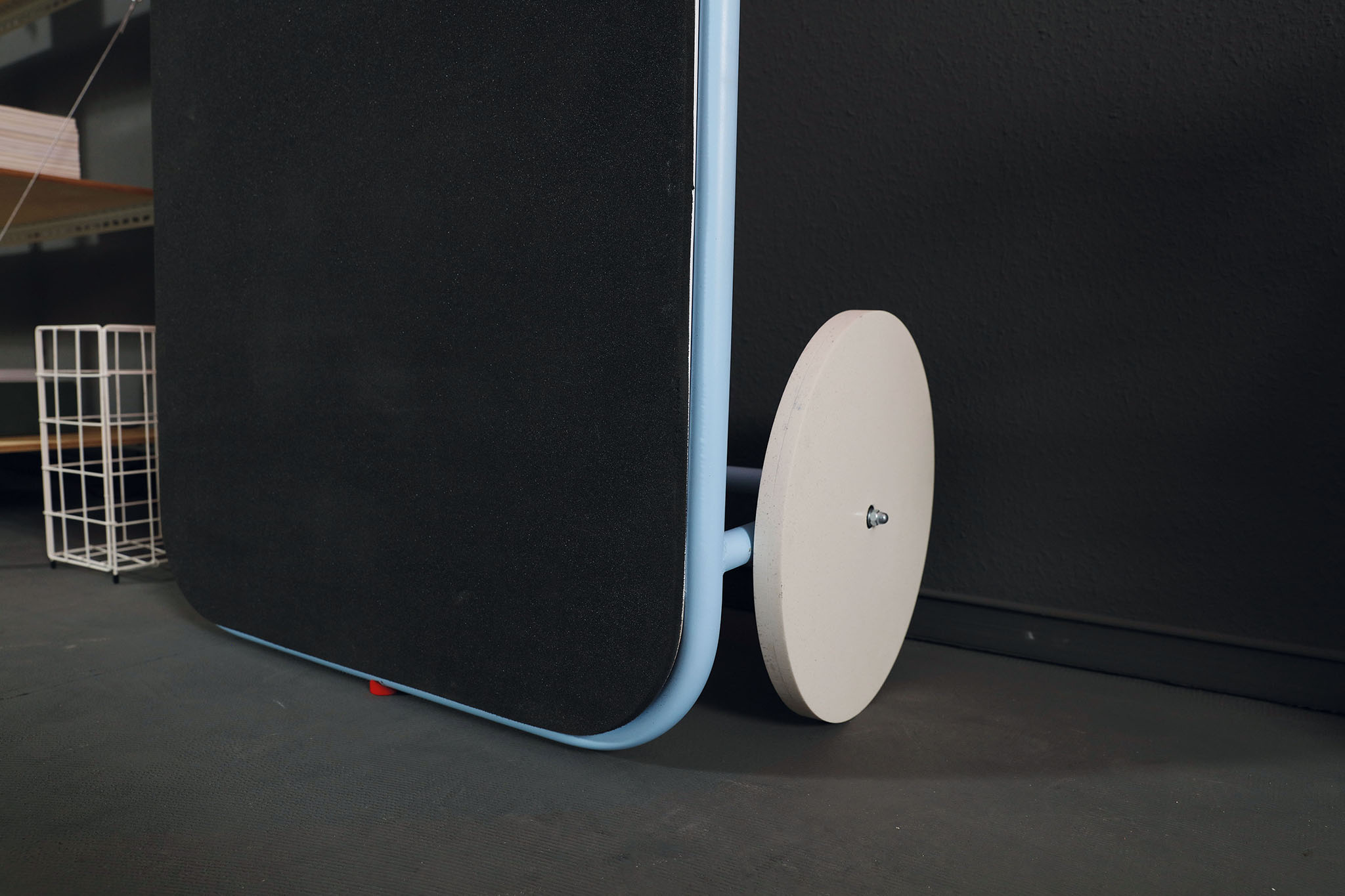

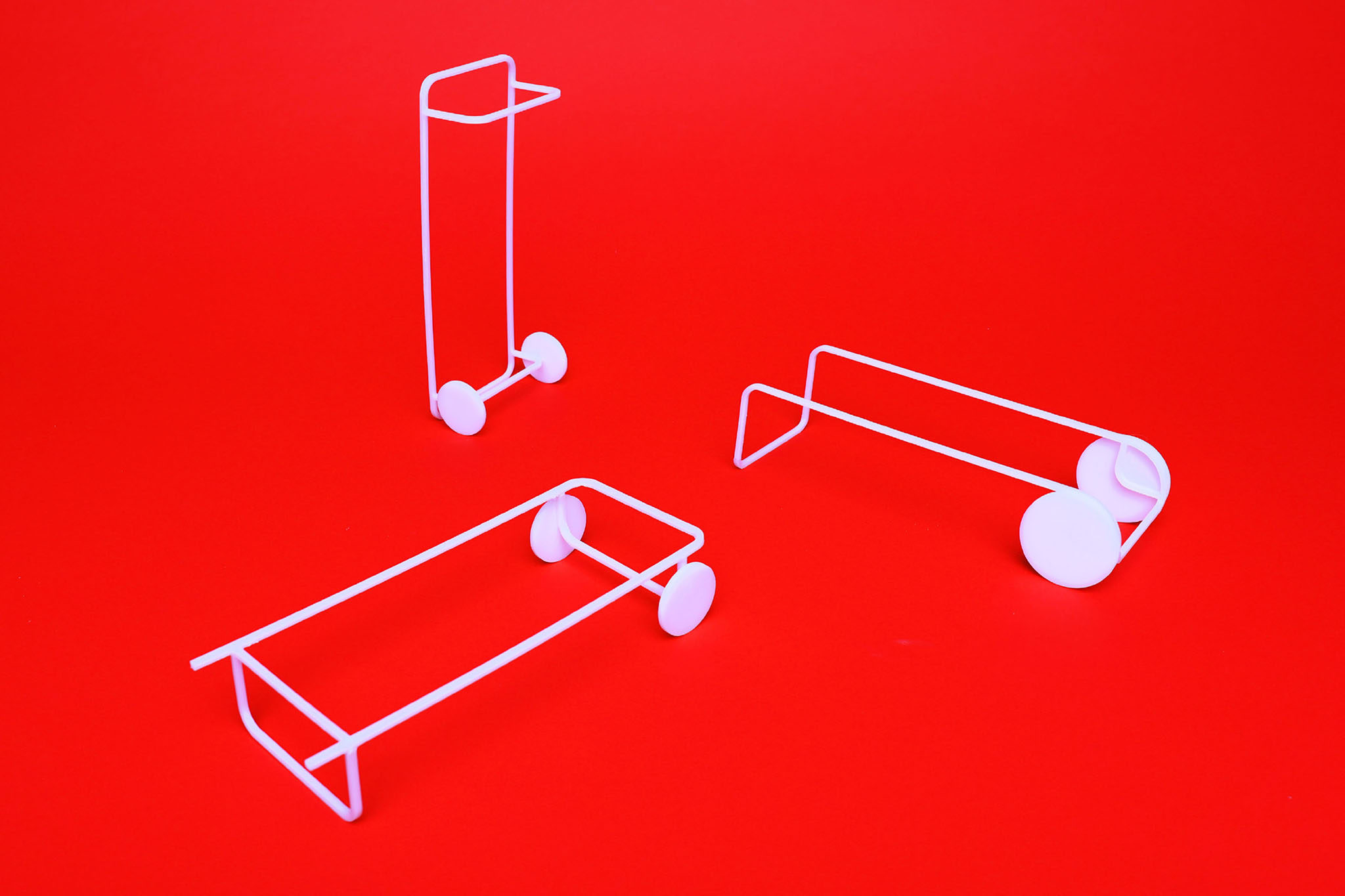

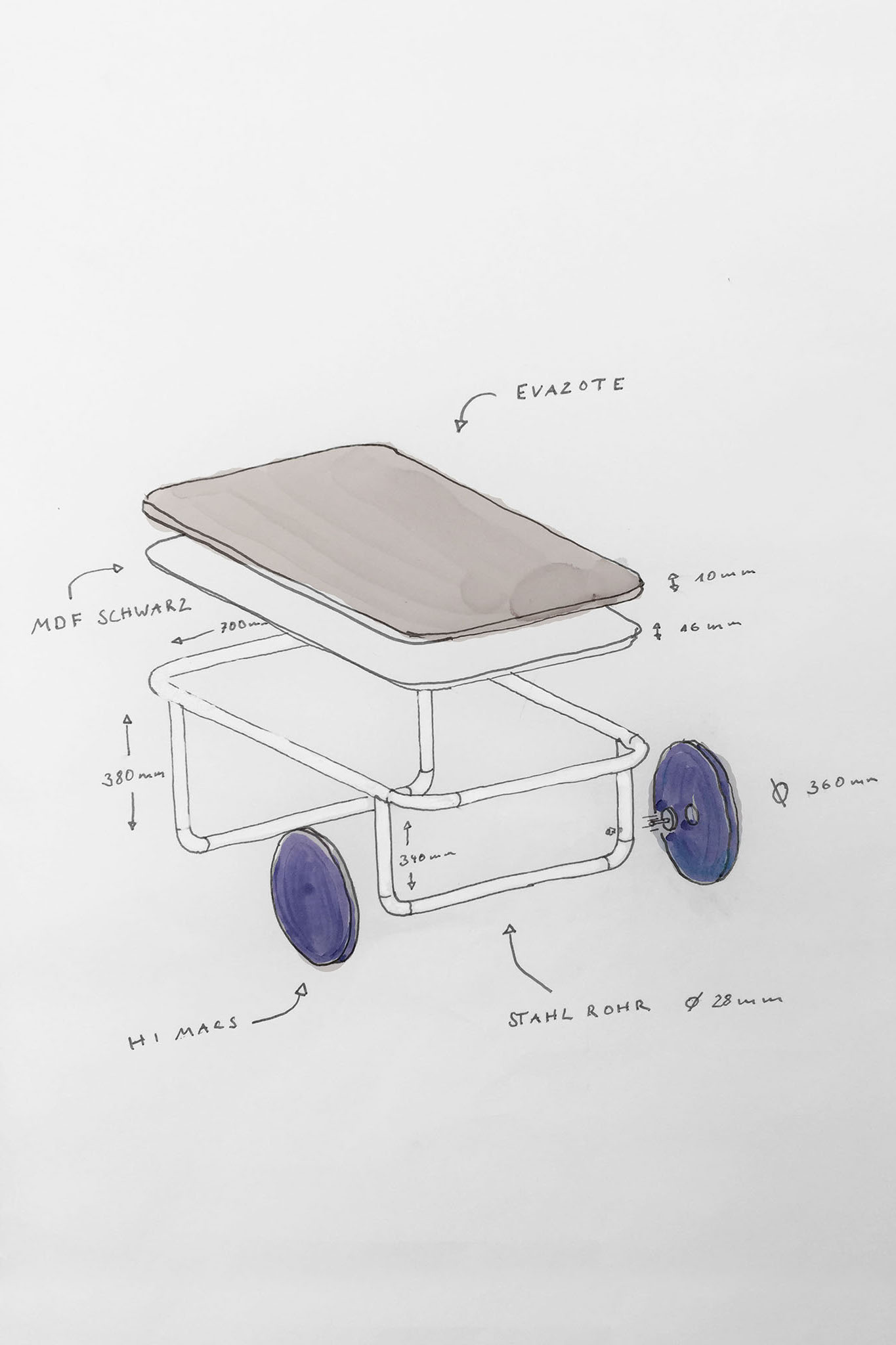

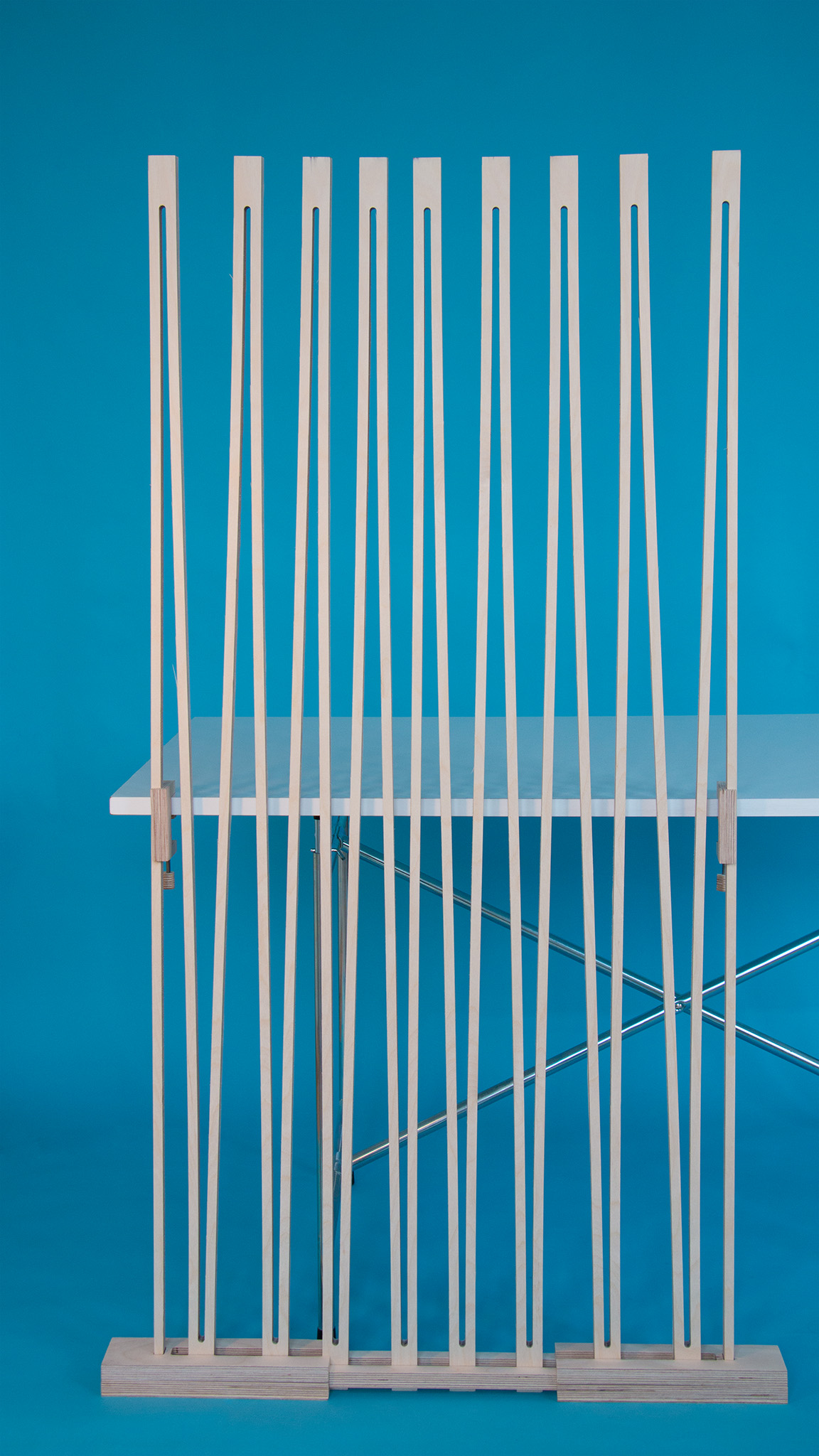

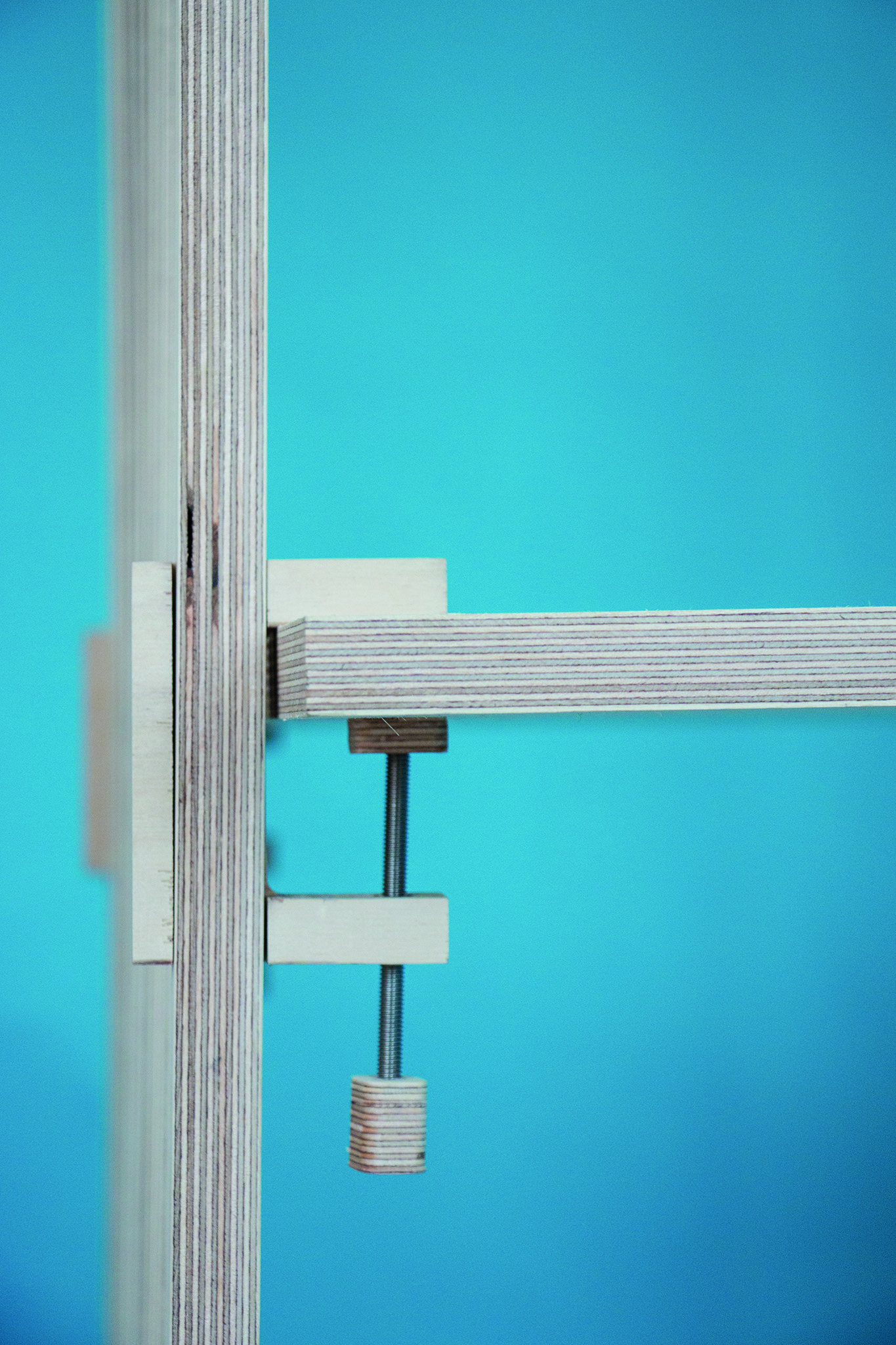

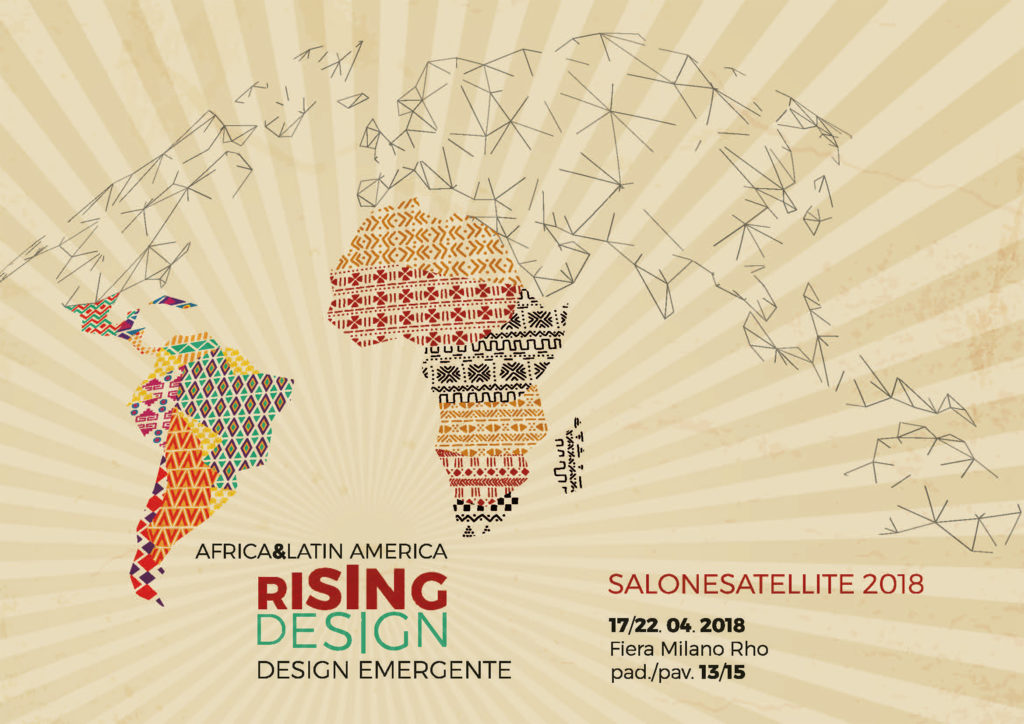

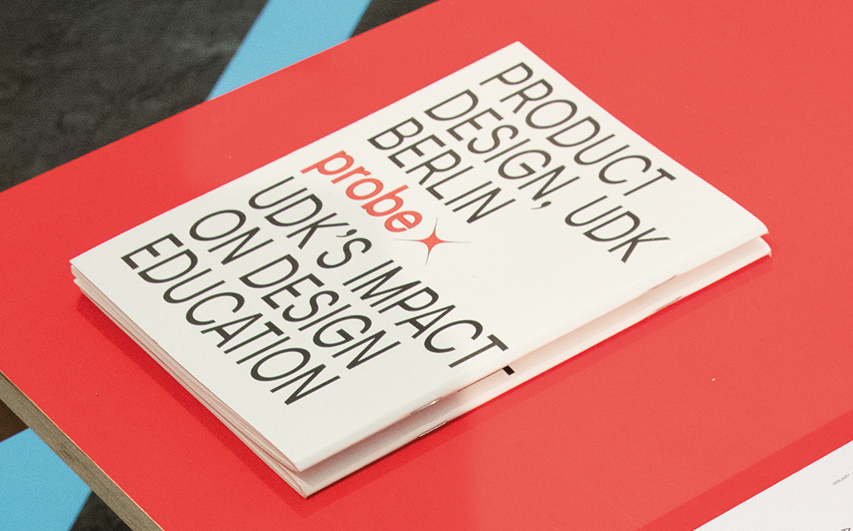

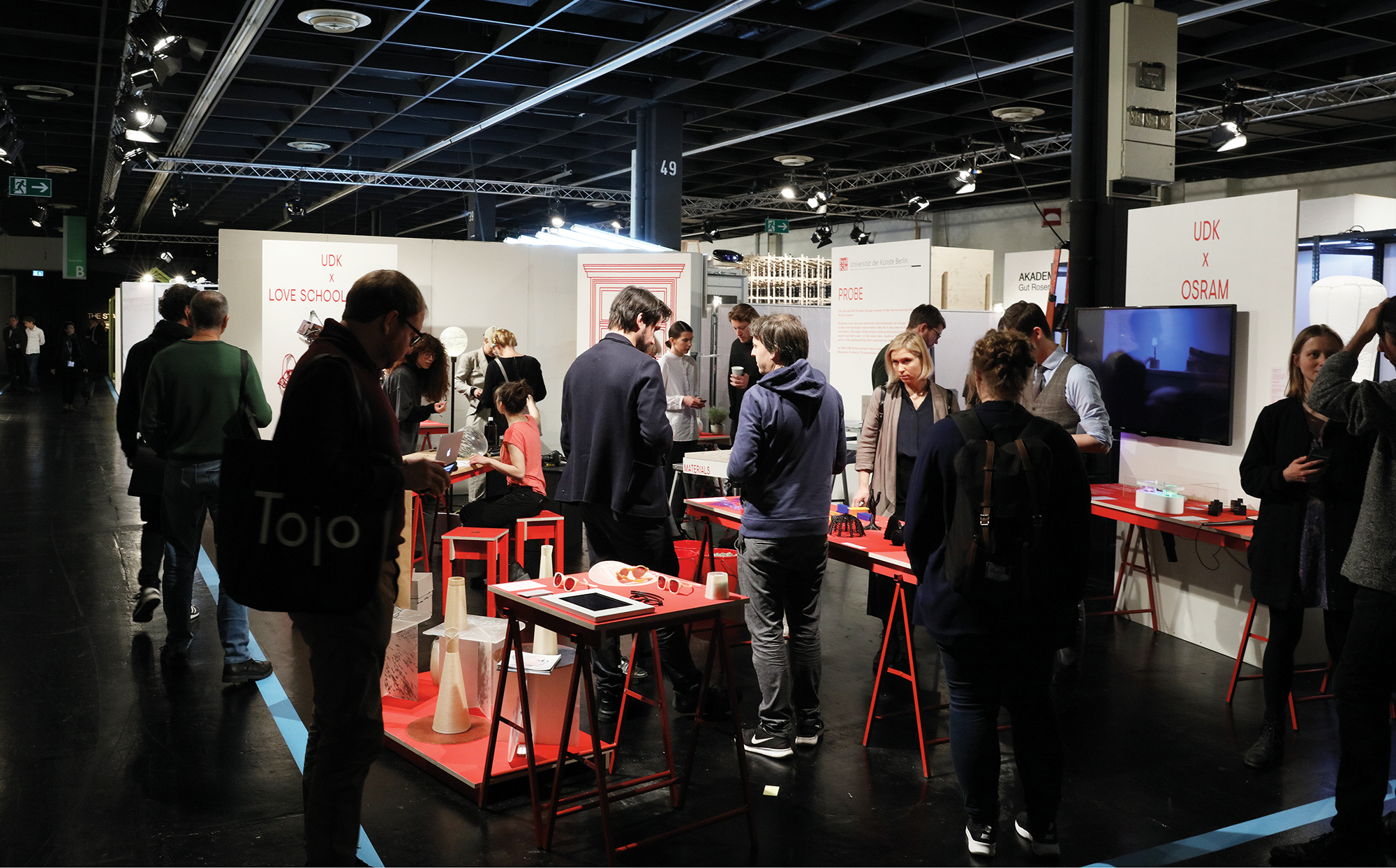

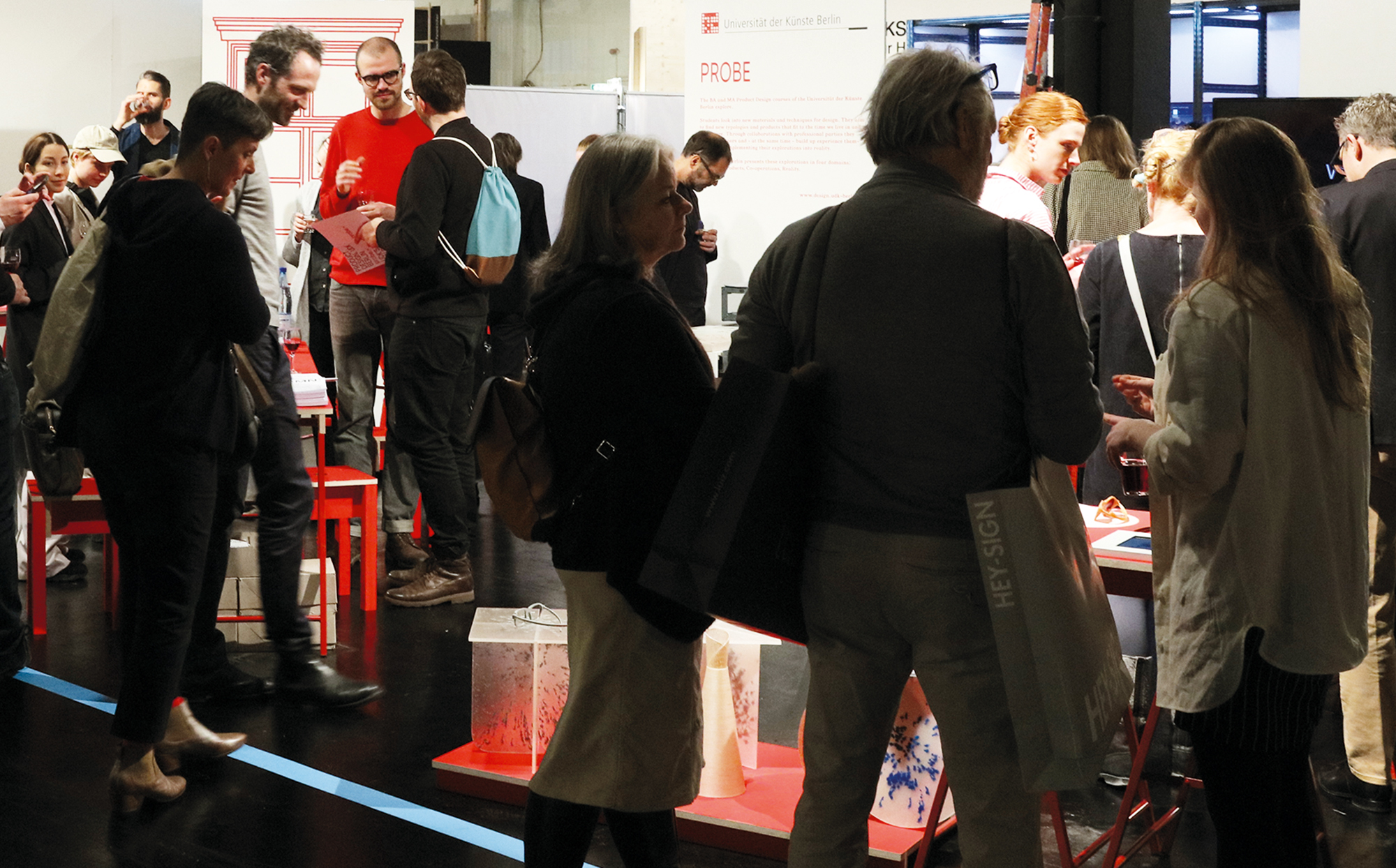

PROBE shows the presentation that Ineke Hans initially prepared with students to show UdK’s produkt design department at the IMM-fair in Cologne. It was than accompanied by a catalogue from acknowledged Berlin Studio Lambl/Homburger. At Cologne it was however selected to be present at the renown SaloneSatellite in Milan. During the Rundgang PROBE pops up a last time in Berlin with both student and graduate projects that show how UdK’s BA and MA Product Design students today explore:looking into newmaterials and techniques for design and aiming to find new typologies and products that fit to the time we live in and our future.

The Outside Showcase of designtransfer shows extracts from the EXPLORE & ACT pamphlet, that is a result from a two year Salon-project that Prof. Ineke Hans ran in London in 2015-2017 and that contains the roots that DESIGN & SOCIAL CONTEXT is based upon.

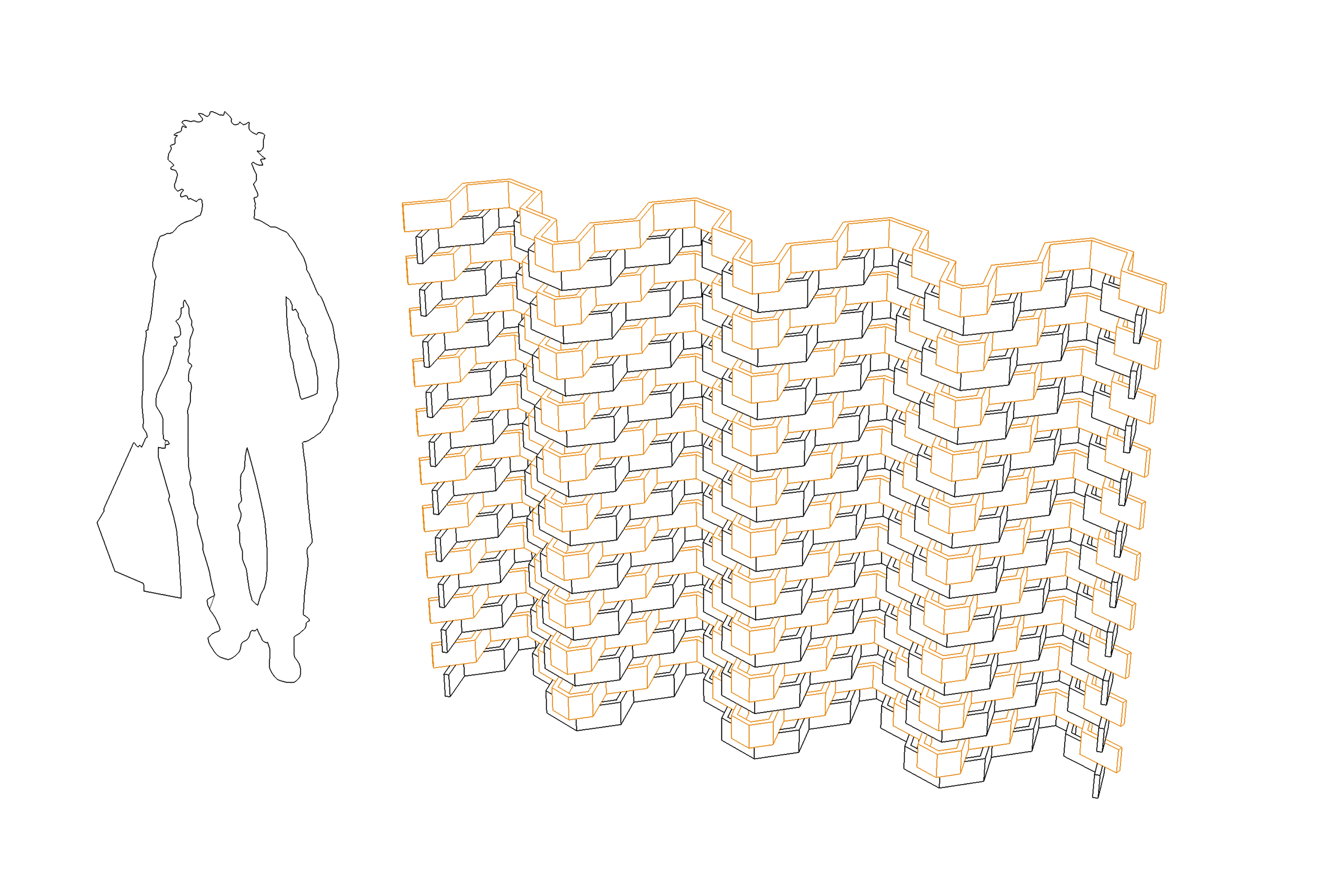

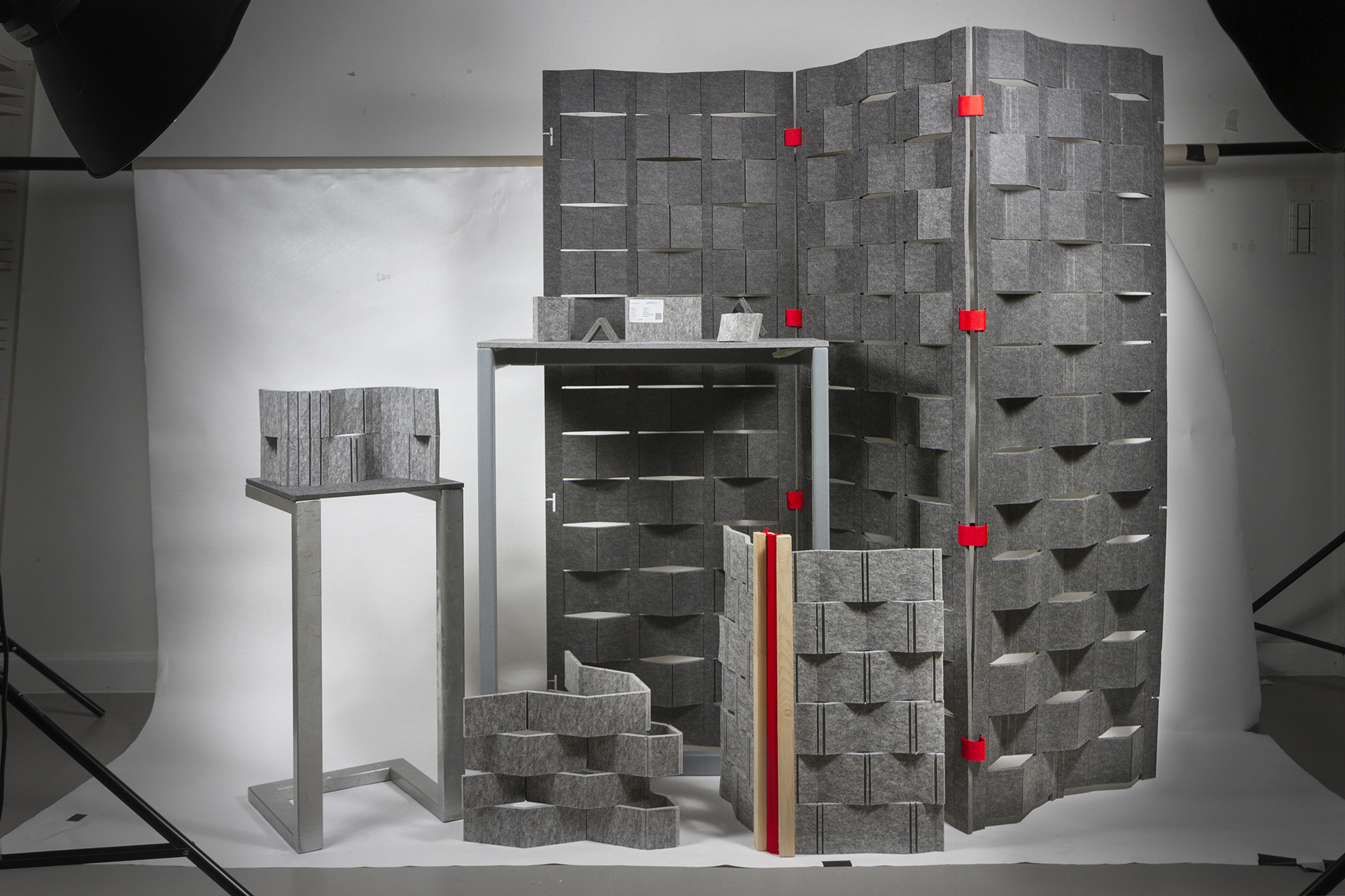

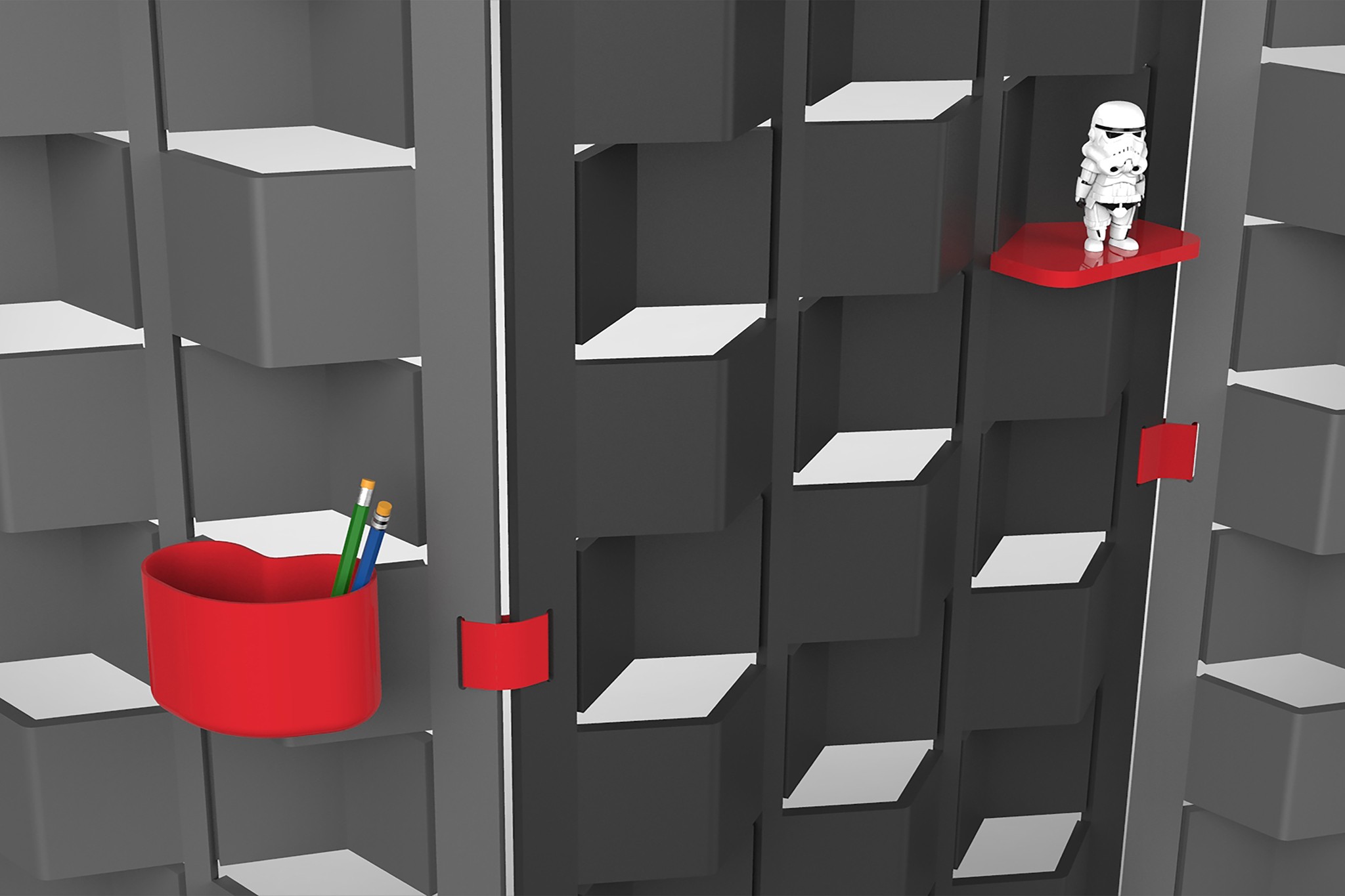

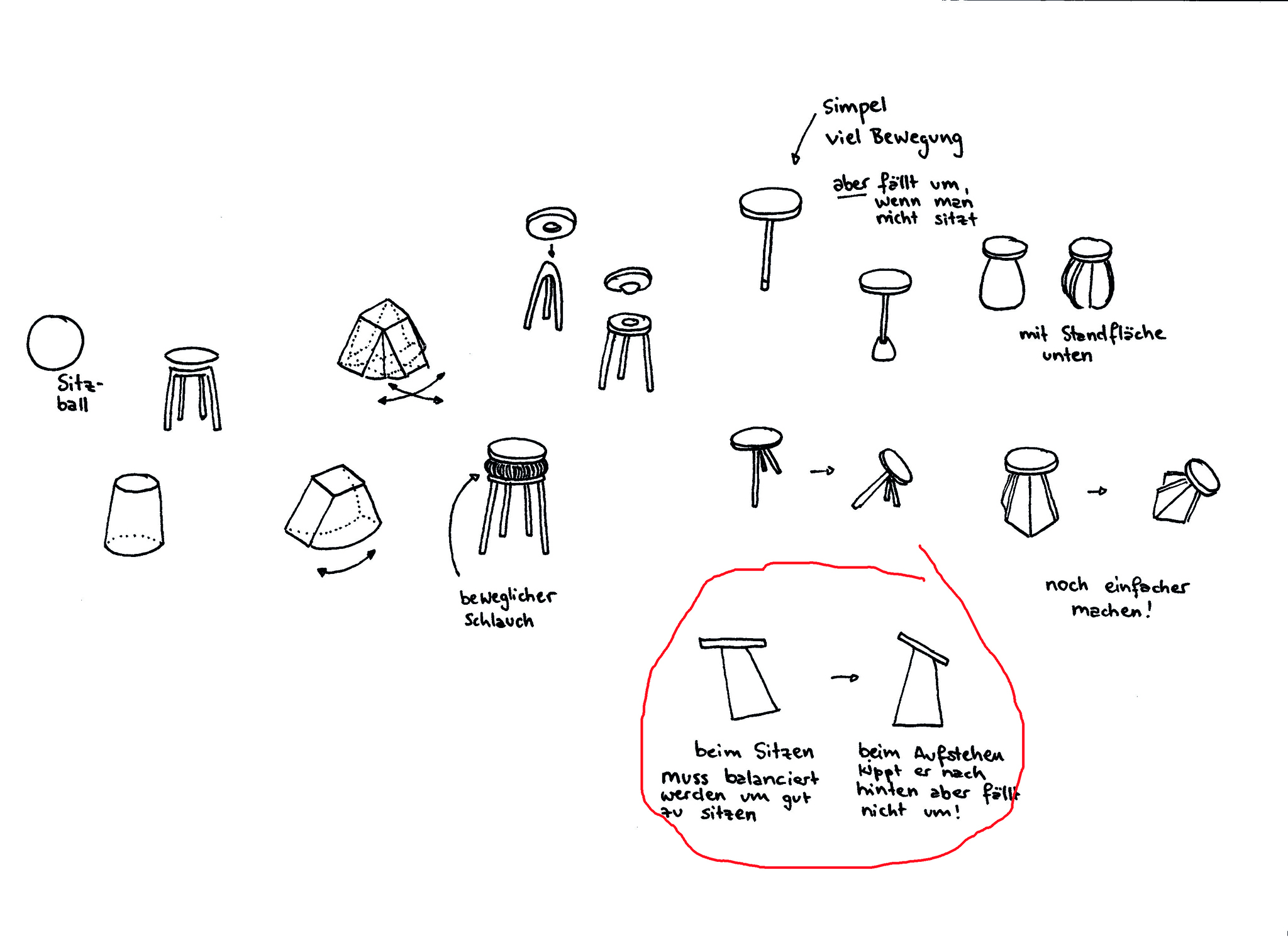

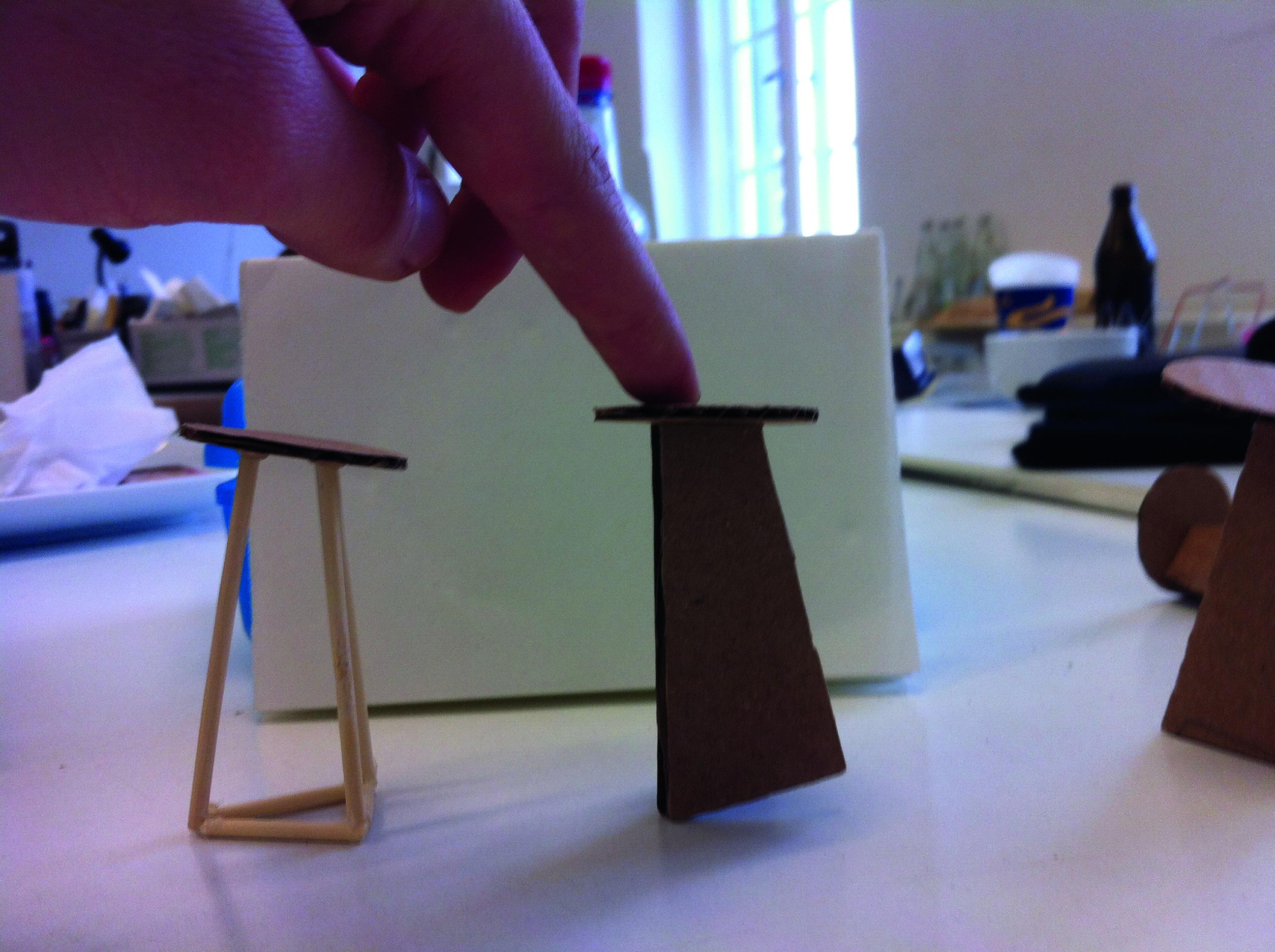

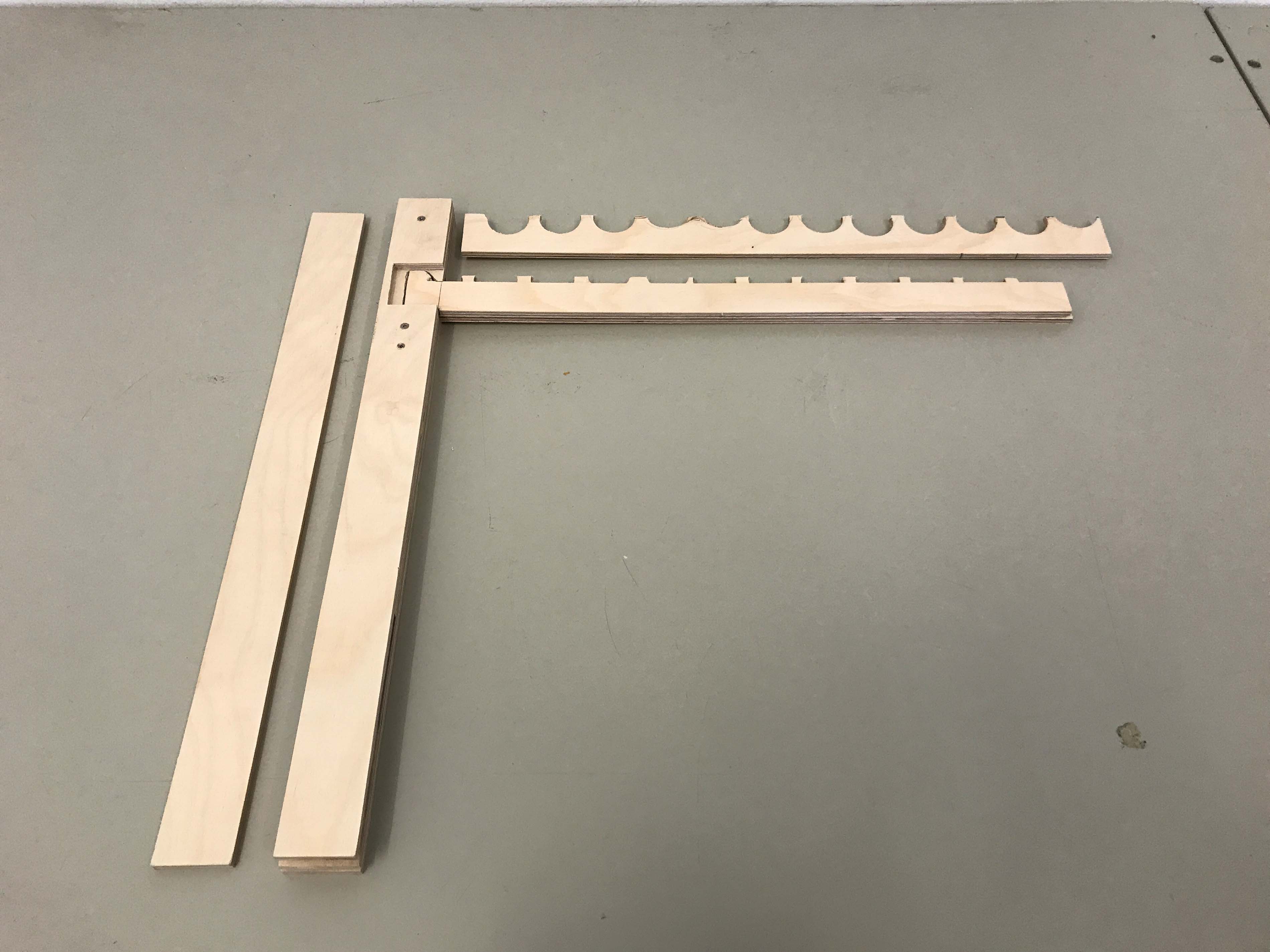

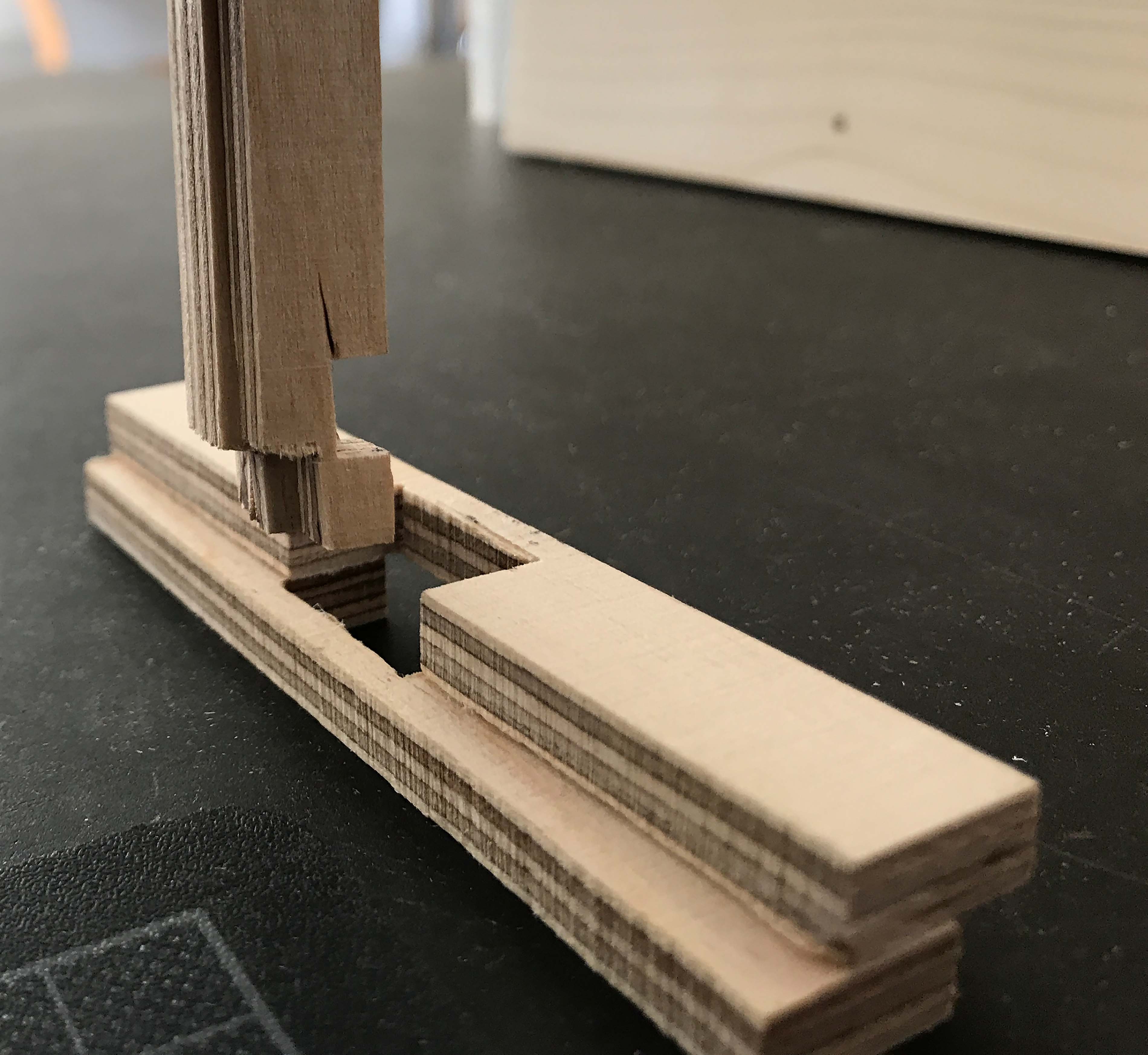

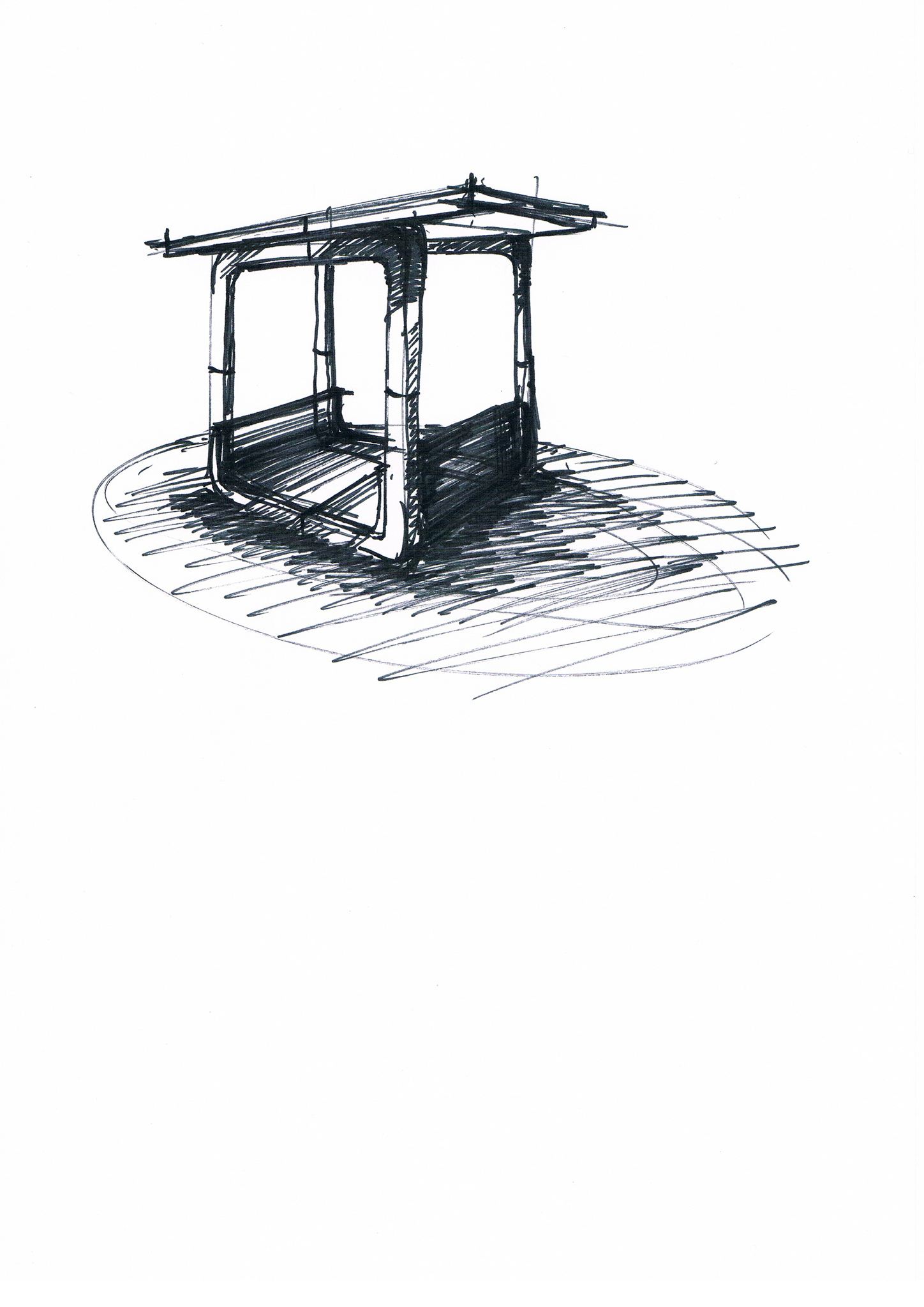

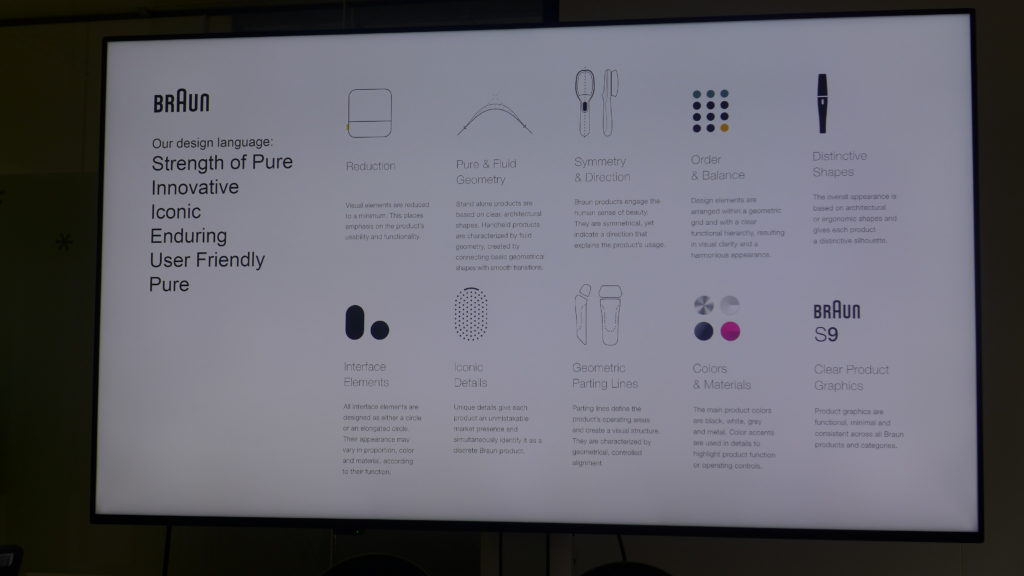

Ineke Hans’s first UdK projects WIR STELLEN UNS VOR (Digital Production / Analogue Production) and results from the DESIGN FOR WHAT MATTERS (Braun competition 2018) that took place in the Winter Semester, will be presented during Rundgang in Project Rooms 202 and 203 of Design & Social Context at Strasse des 17. Juni 118.

The exhibitions at designtransfer will close with a festive finissage on Sunday 22 July 18.00 hours after the Sense & Sustainability Symposium.

times and locations popup expo’s

Wednesday-Sunday 18-22 July, 10:00-18:00,

• designtransfer: Einsteinufer 43, Berlin

• 3D Haus room 202 and 203: Strasse des 17. Juni 118, Berlin

Festive Finnisage at designtransfer: Sunday 22 July 18:00

links

Summer Semester projects (2018):

• power house

• celebrating glass

• cafetaria project

Winter Semester projects (2017/2018):

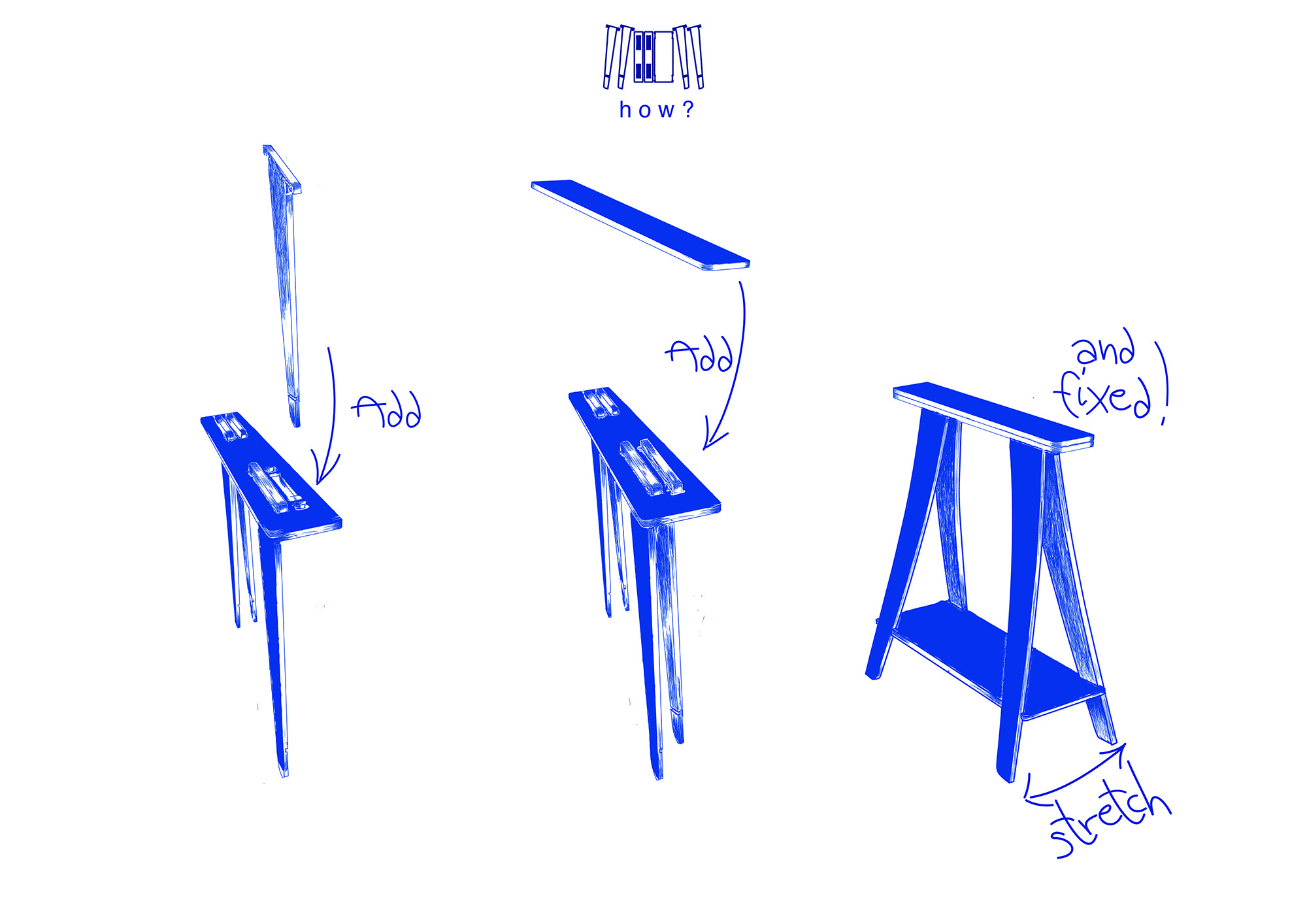

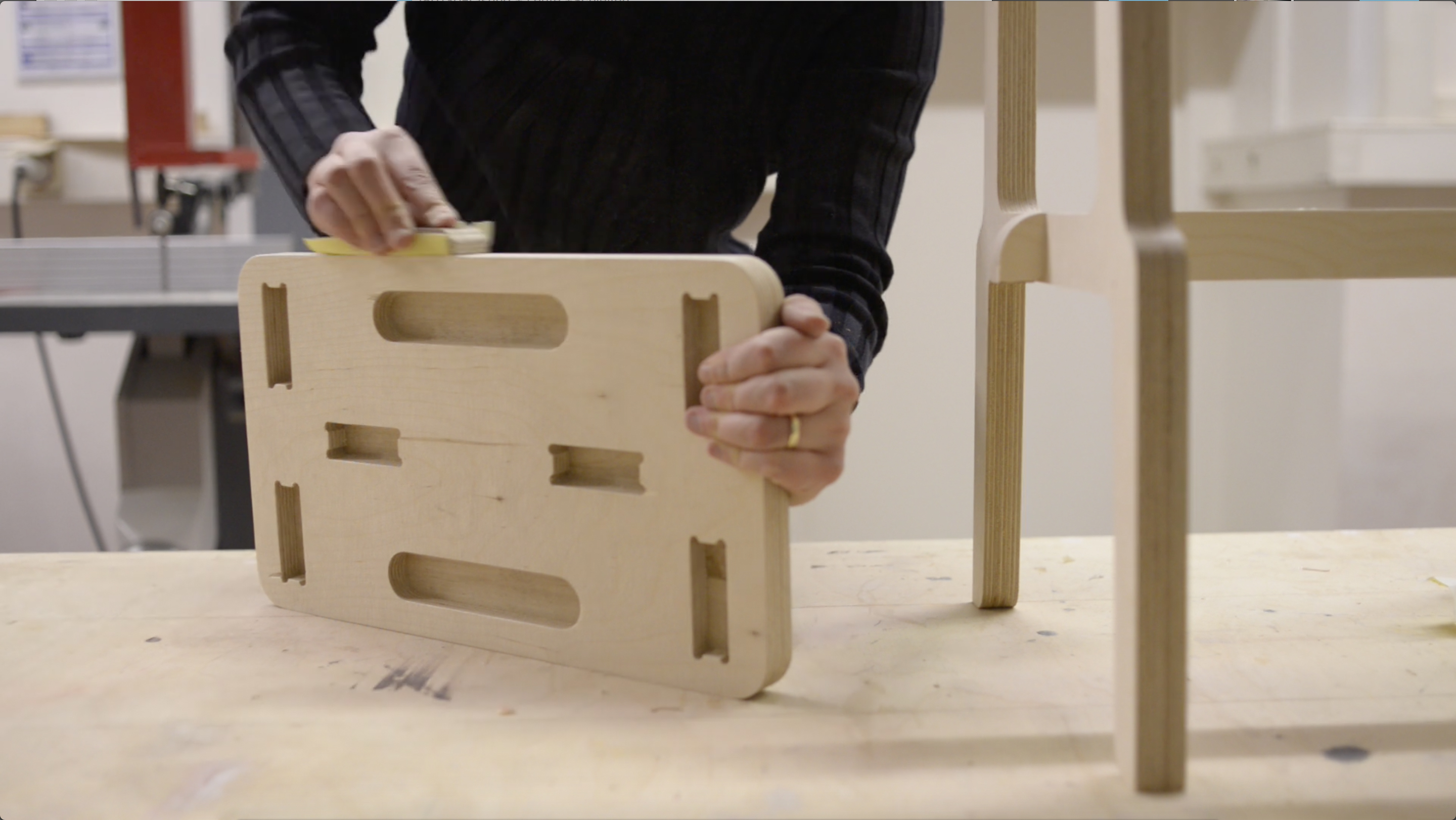

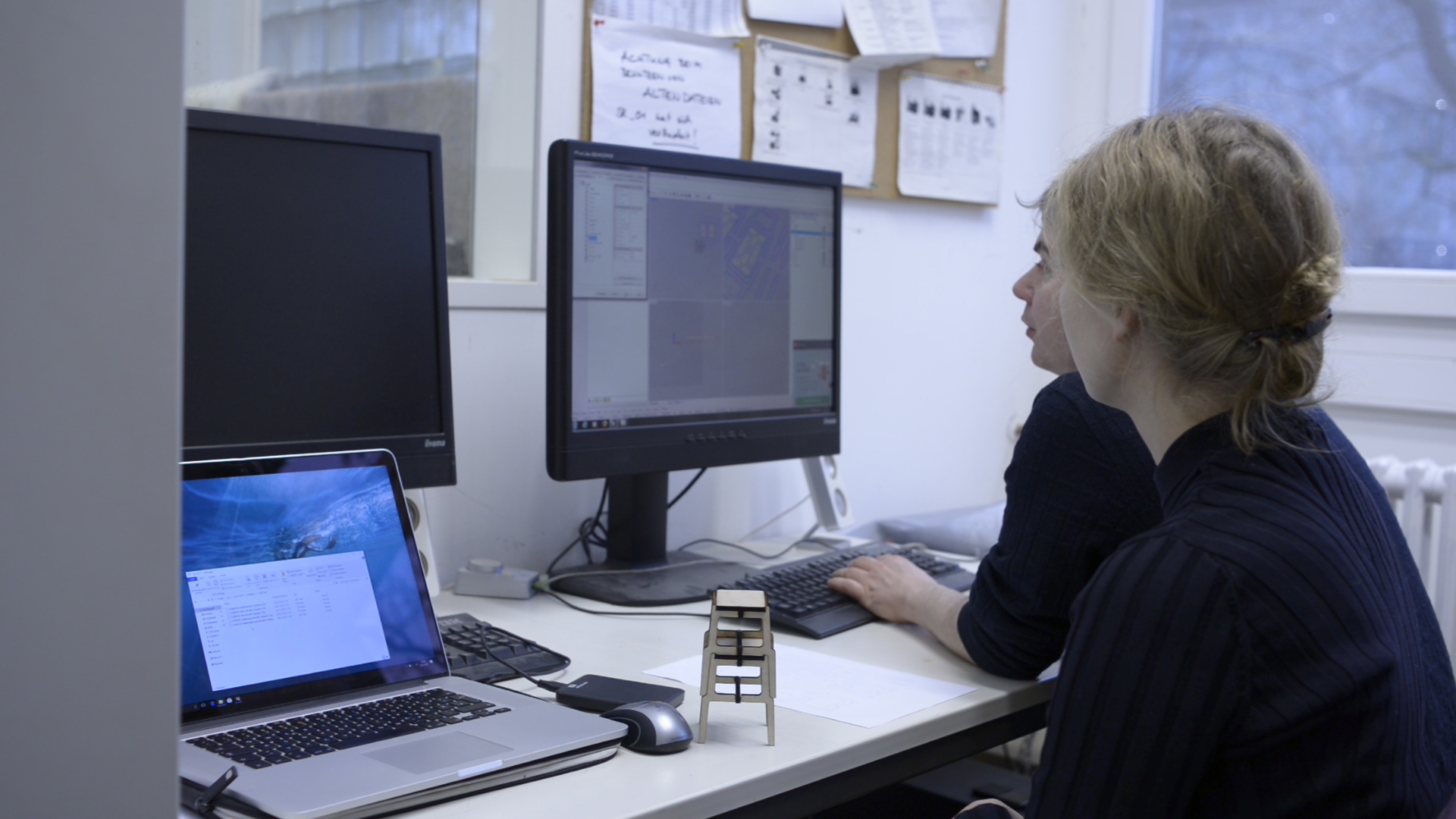

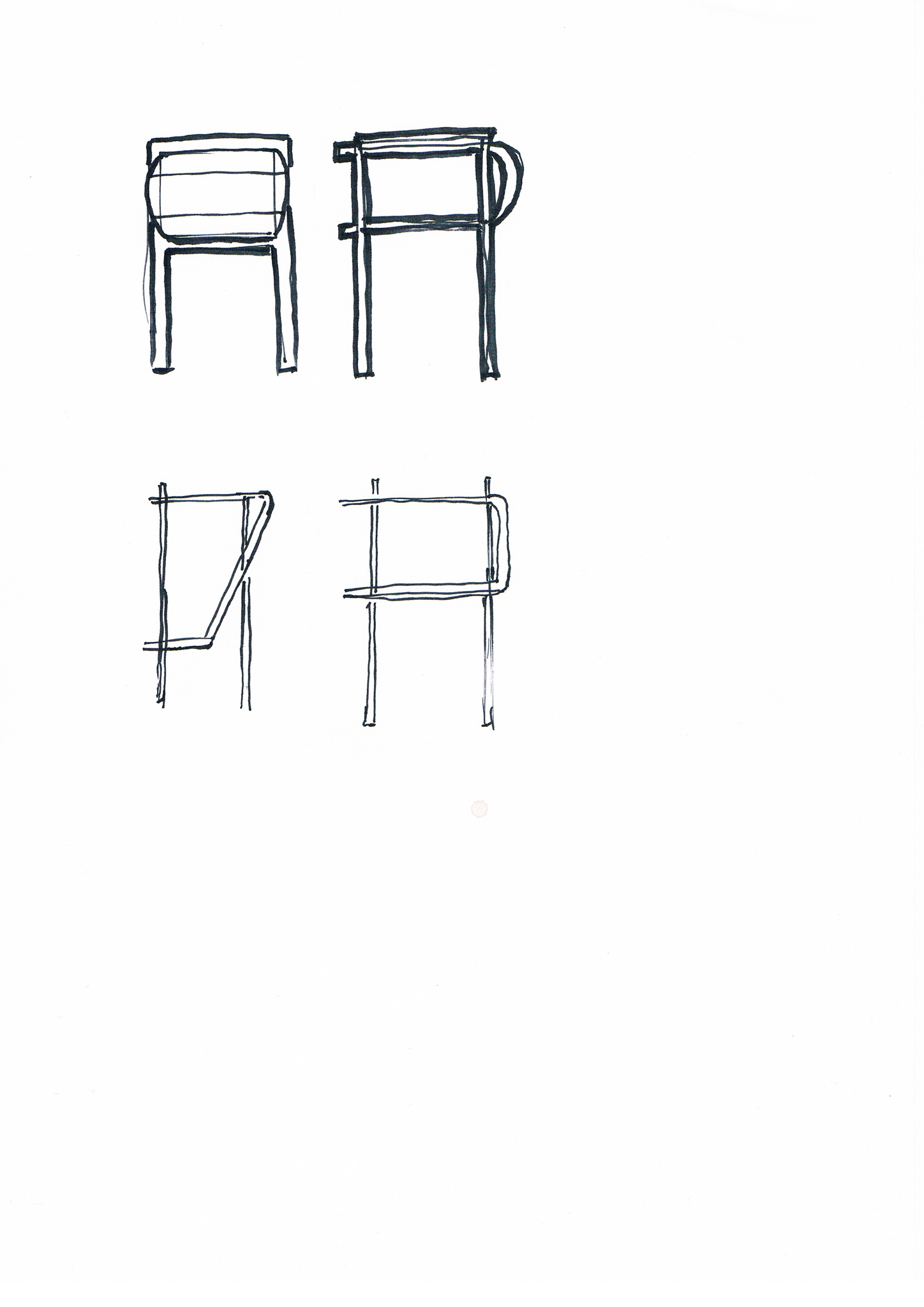

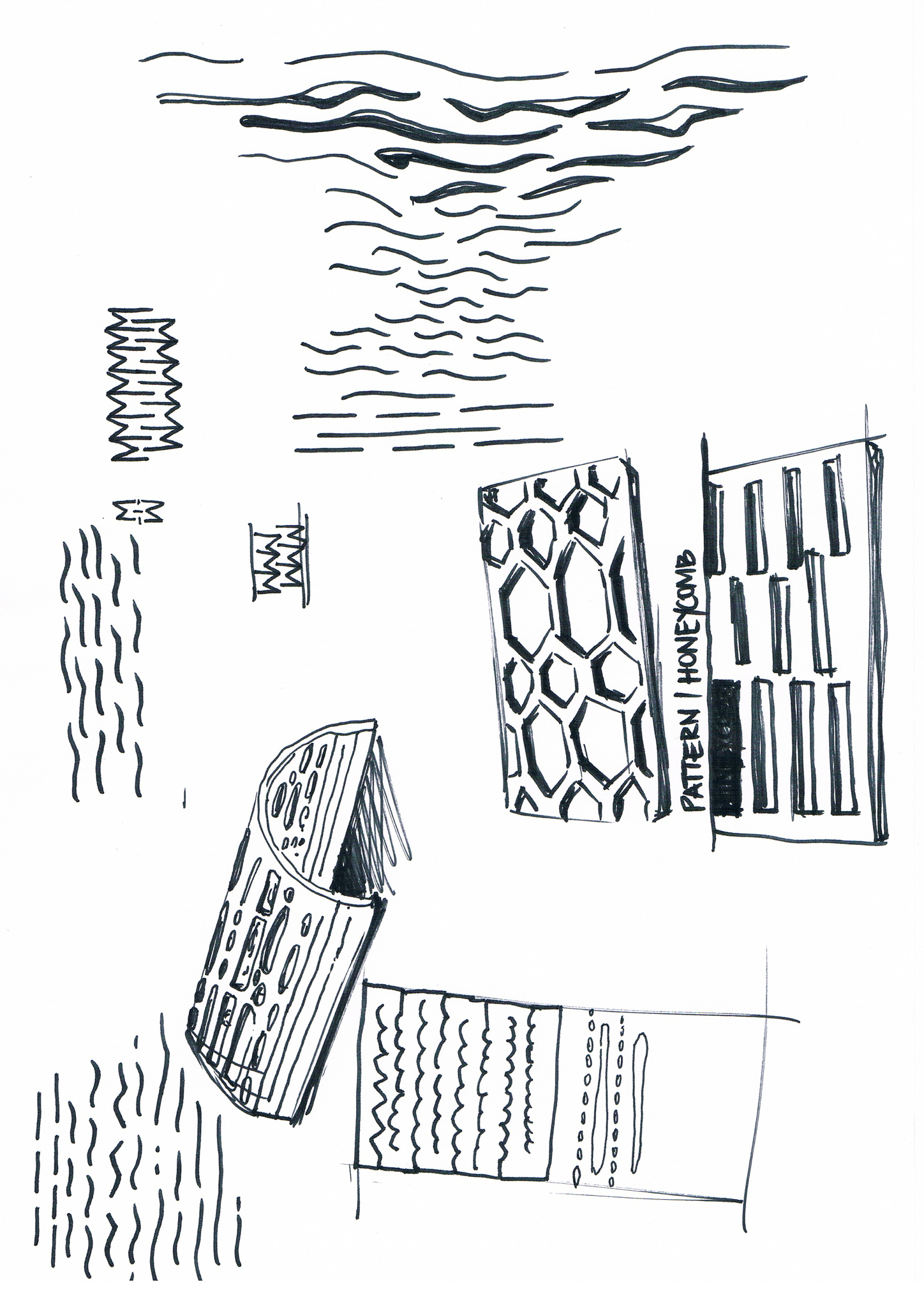

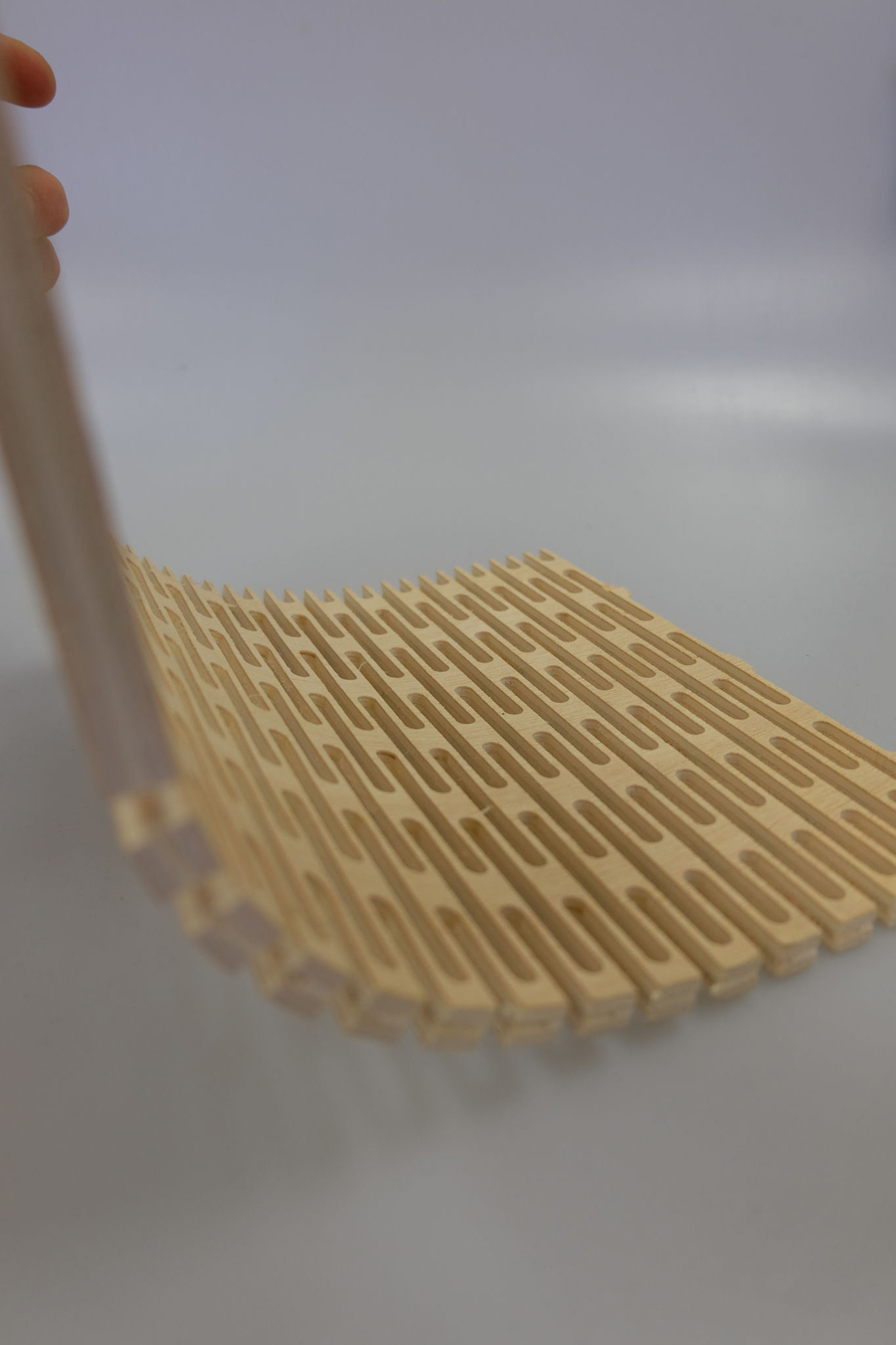

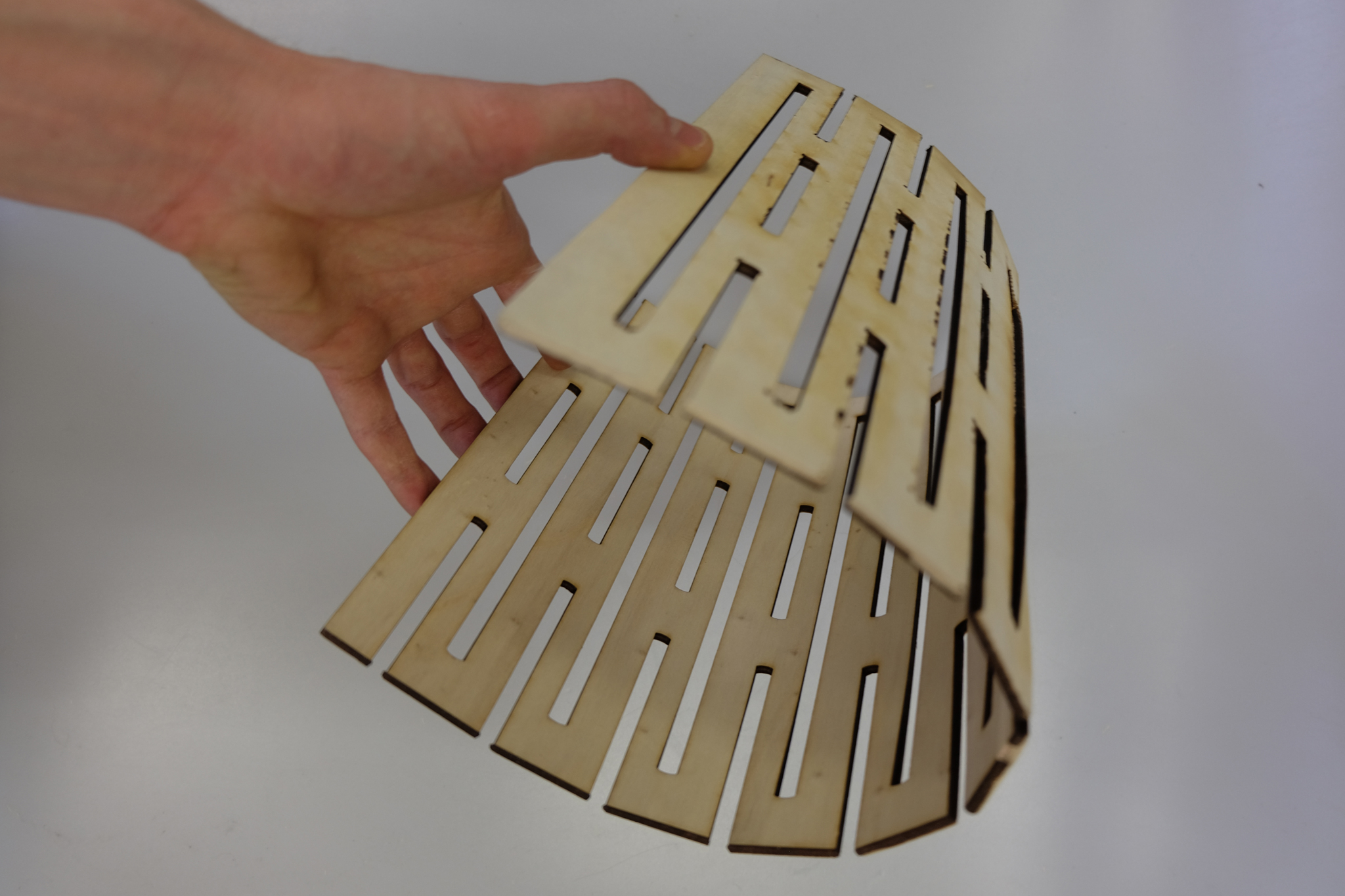

• wir stellen uns vor – digitale production

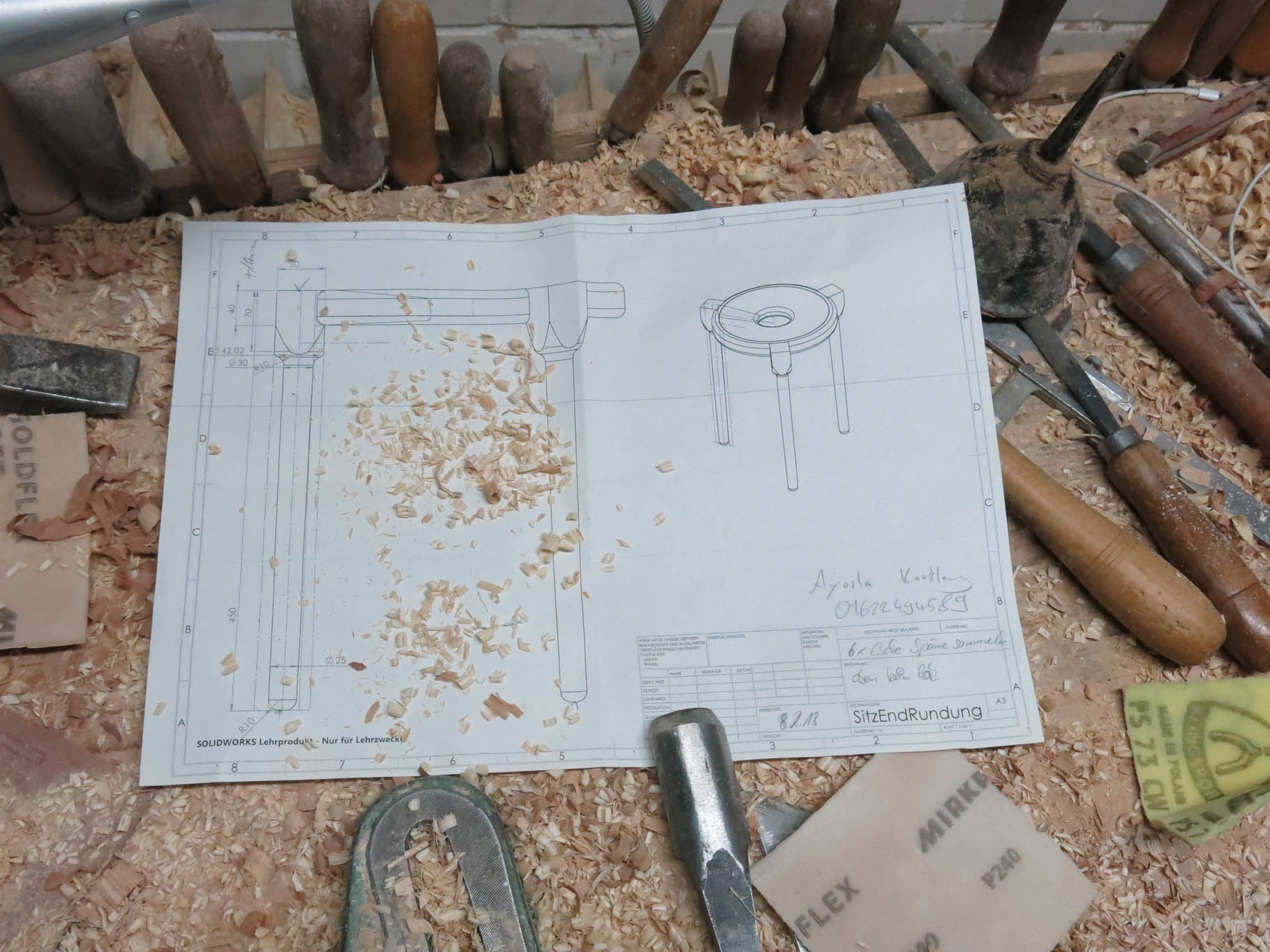

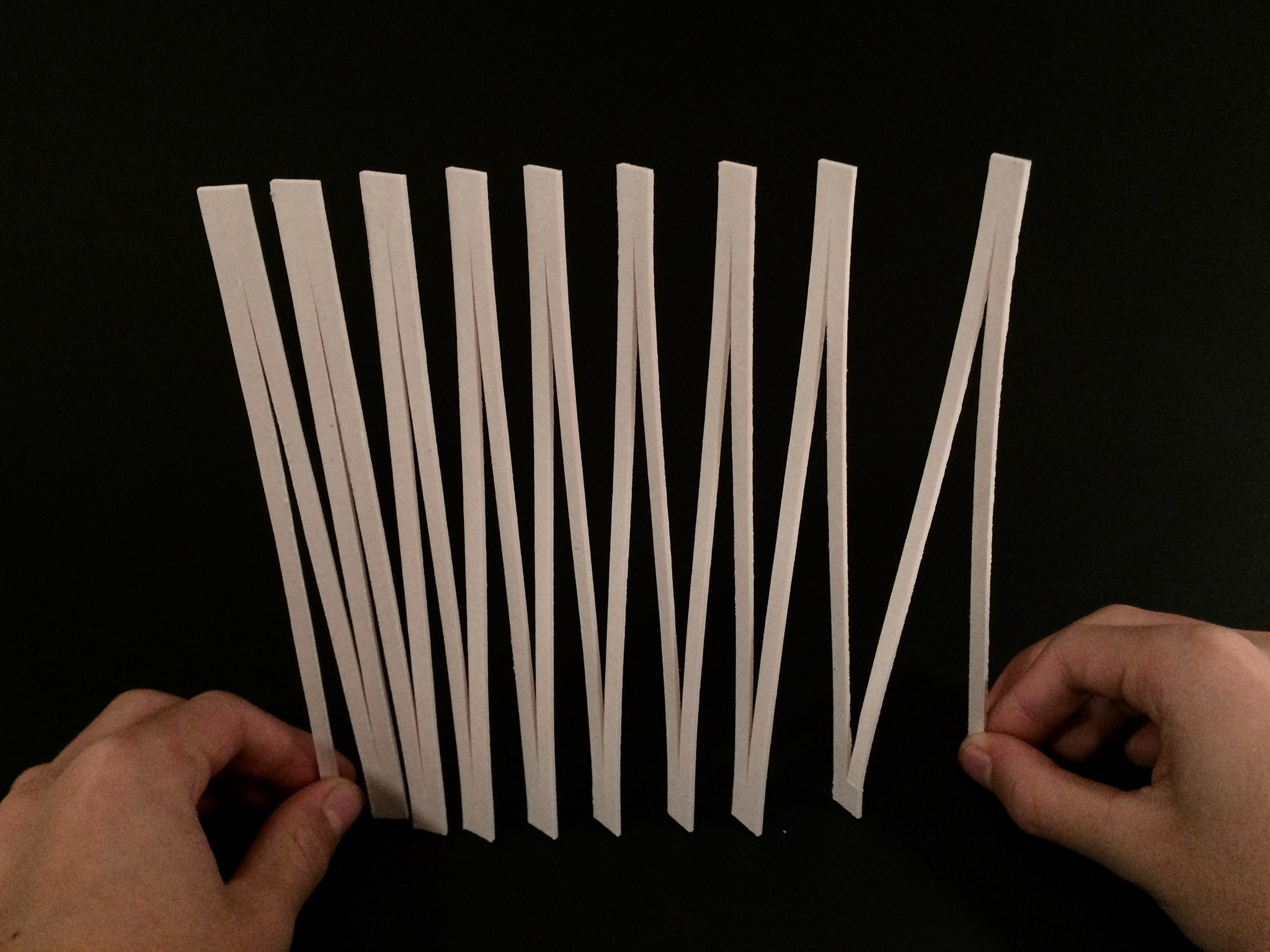

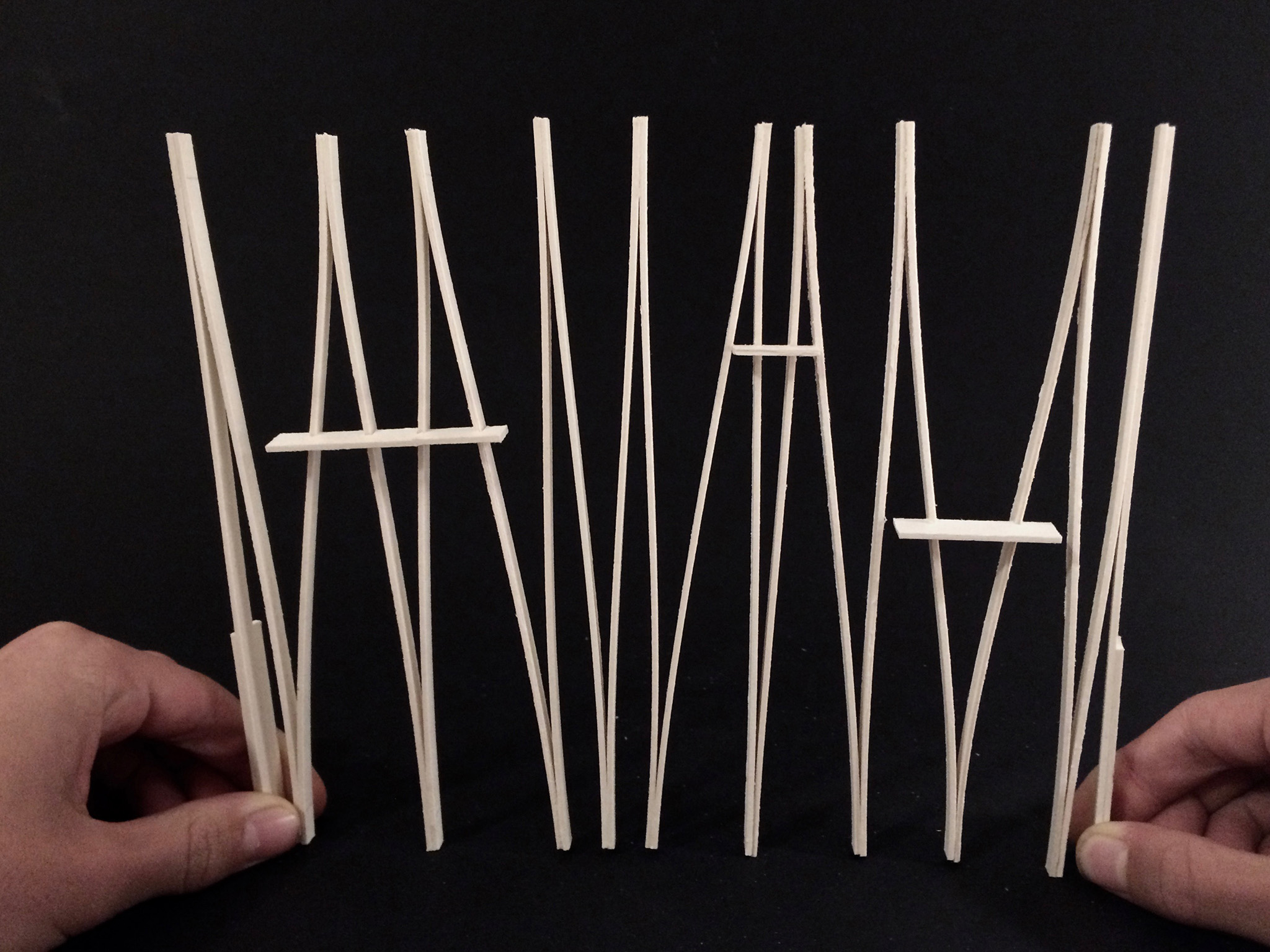

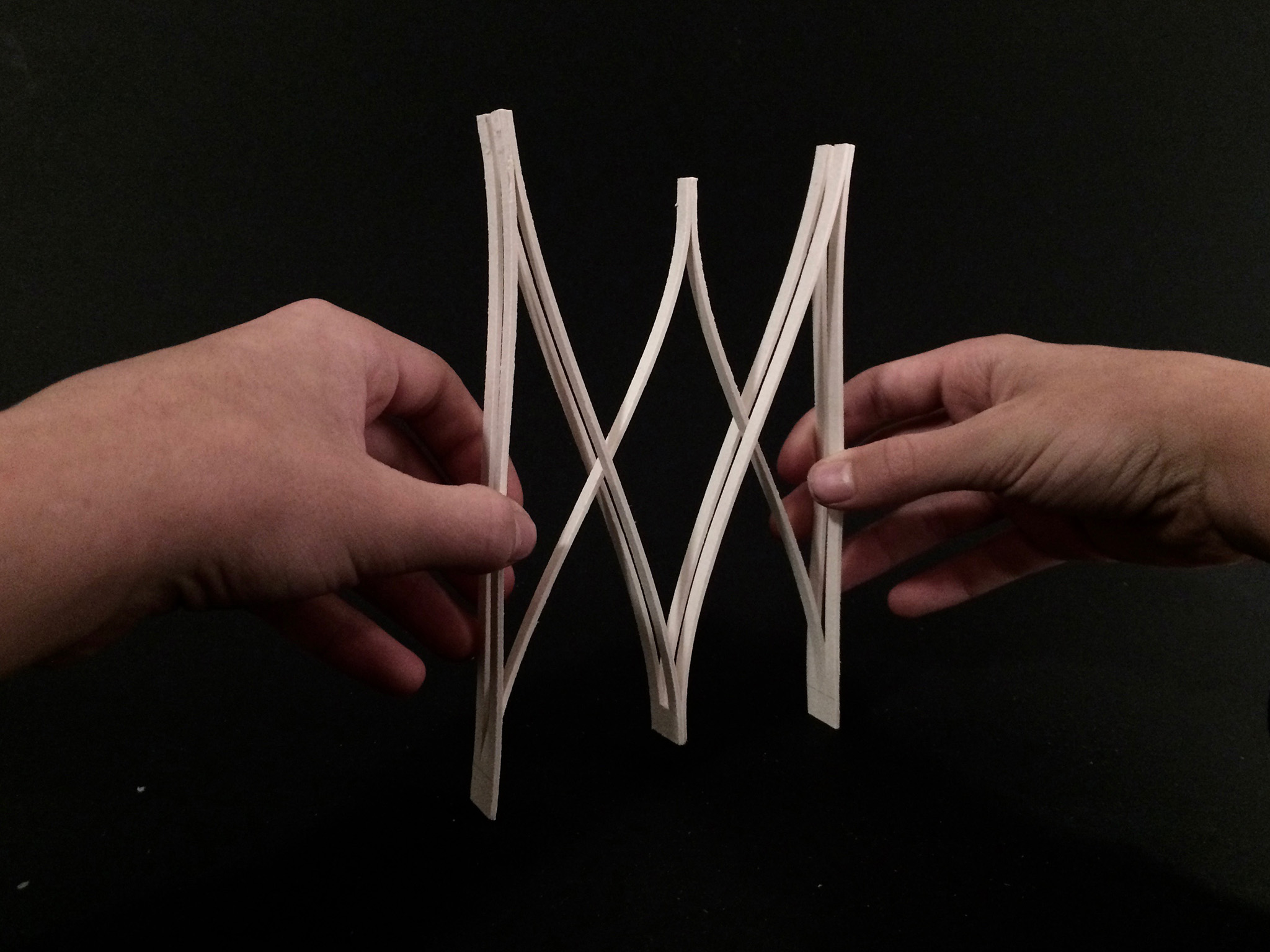

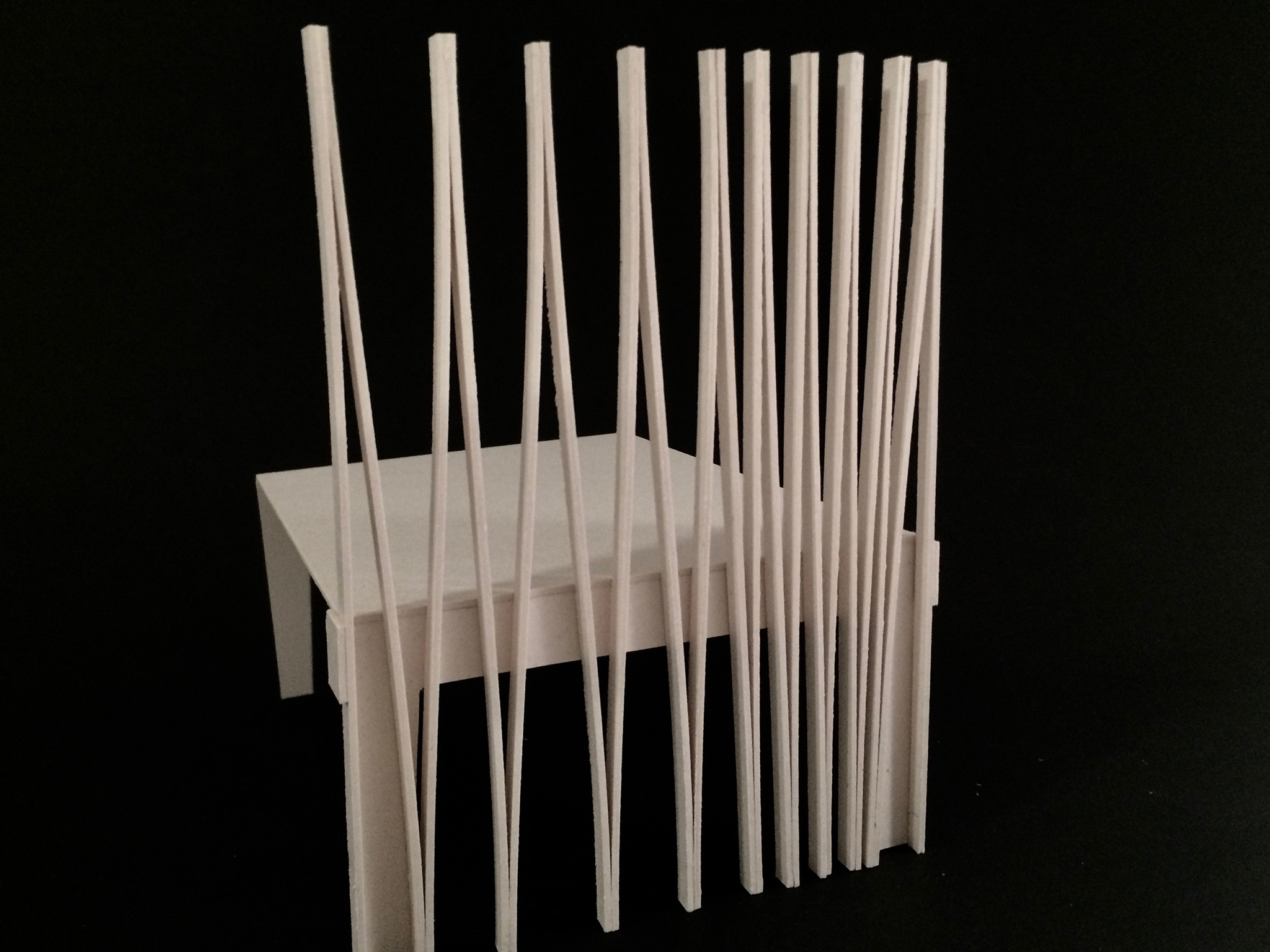

• wir stellen uns vor – analoge production

• braun – design for what matters

Other:

• probe cologne

• probe milan

• explore and act

dinner with visiting tutor Mathias Hahn

dinner with visiting tutor Mathias Hahn

breakfast at Inekes studio in London

breakfast at Inekes studio in London visit at Victoria & Albert Museum

visit at Victoria & Albert Museum

visit at Vessel Gallery

visit at Vessel Gallery

climate action challenge

climate action challenge

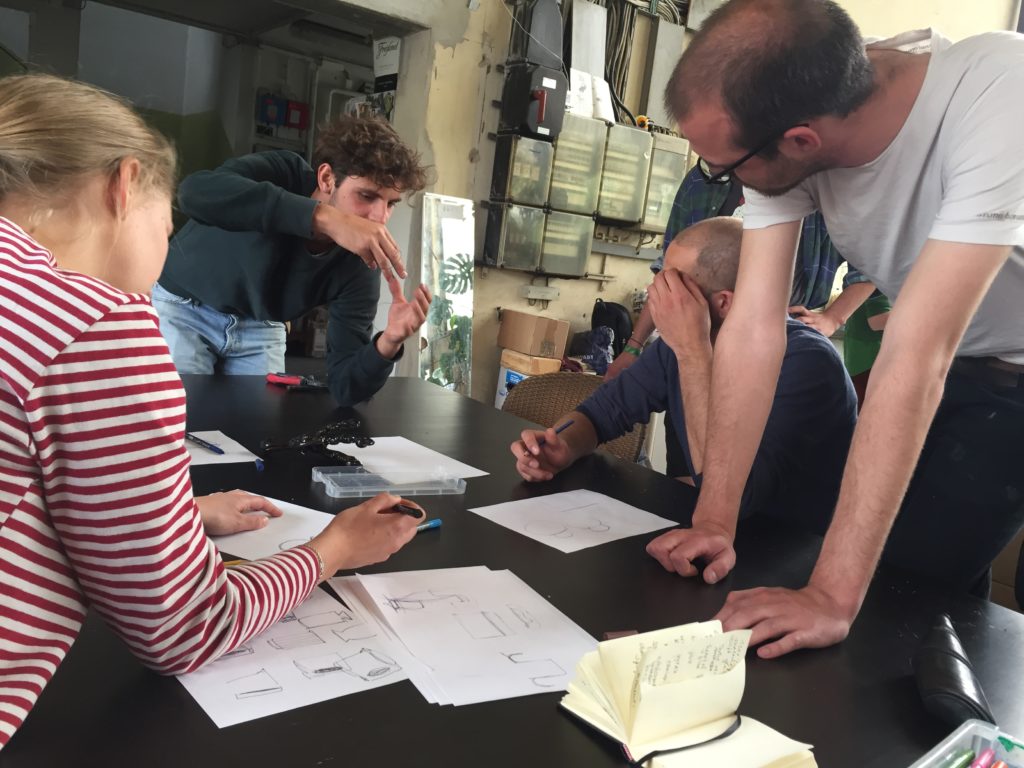

meeting with HbK Saar

meeting with HbK Saar off to meeting space with Marcus Fairs of Dezeen

off to meeting space with Marcus Fairs of Dezeen

citywalk

citywalk dutch invertuals

dutch invertuals

van abbe museum

van abbe museum

envisions

envisions

Chinese take away at STUDIO INEKEHANS Arnhem

Chinese take away at STUDIO INEKEHANS Arnhem

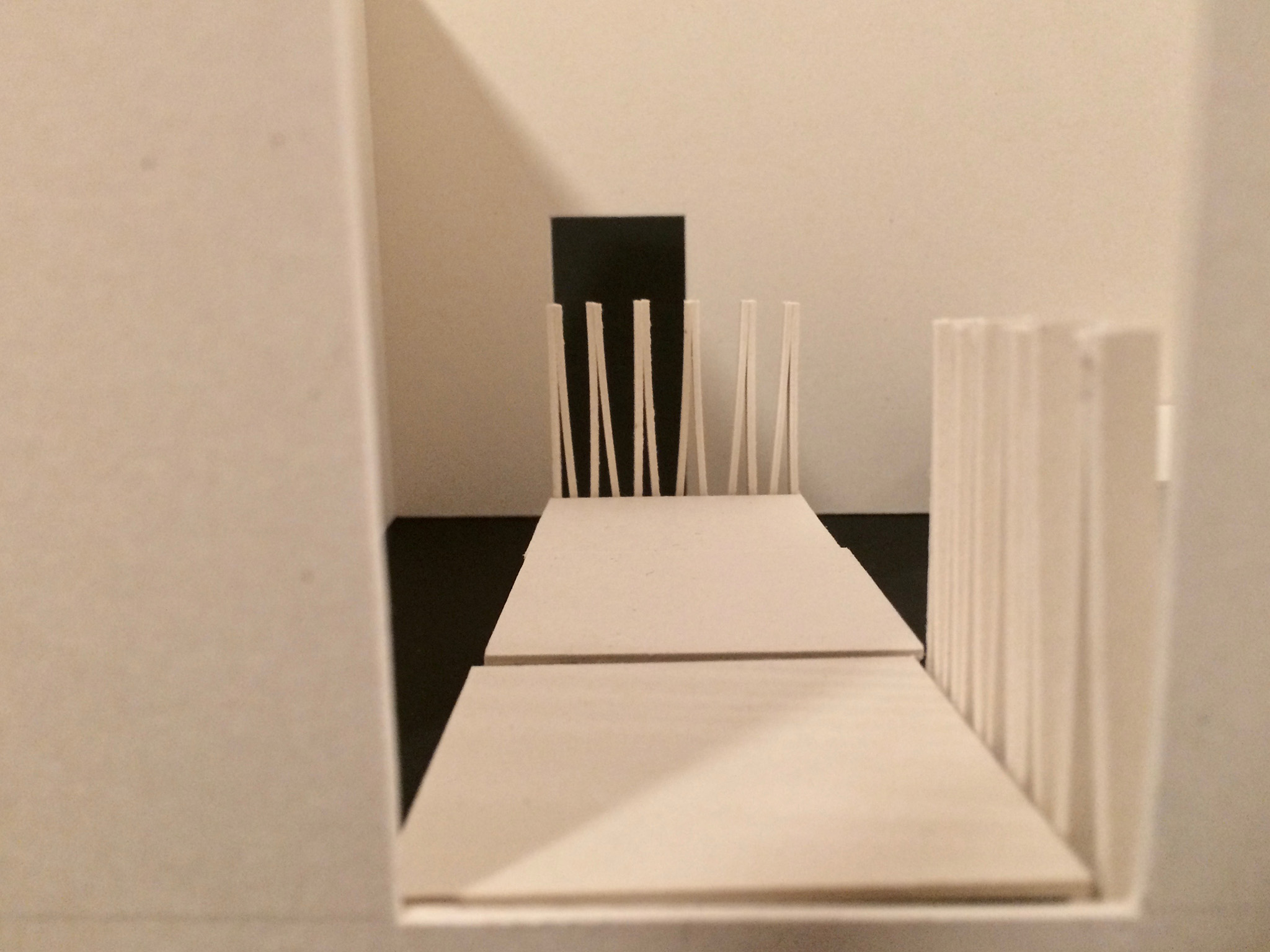

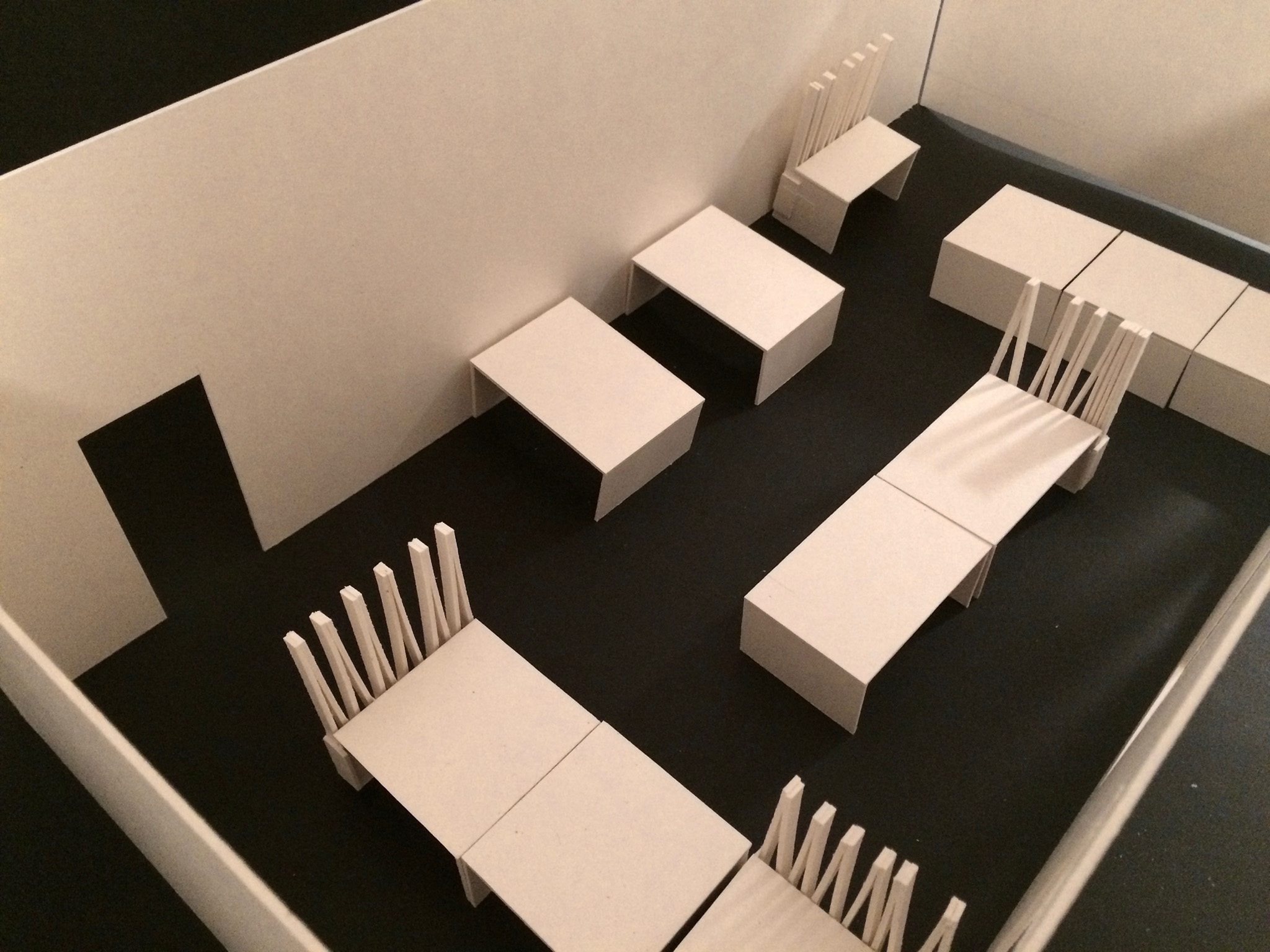

The Love School project, WiSe 2016/17

The Love School project, WiSe 2016/17

progress

progress progress

progress

guided tour through Braun modeling department

guided tour through Braun modeling department

presentation of design work at Braun today with question round

presentation of design work at Braun today with question round

at Braun museum

at Braun museum